www.dalemans.com

DAT420_MAN02_EN.docx • V1R1

6

DAT 420

6.

CALIBRATION OF DETECTOR

To properly calibrate the detector, the following operations must always be performed in the correct order :

1. Adjustment of the detector zero setting (ZEROING);

2. Adjustment of the detector sensitivity (CALIBRATION).

Avoid touching the transmitter circuit or any of the electronic components during the entire adjustment

procedure on the 4..20 mA transmitter inside the sensing head.

BEFORE opening the detector junction box or its sensing head :

•

Check that the hazardous area has been declassified.

•

Check, using portable equipment, that there is no dangerous gas present in the

atmosphere of the working area.

•

Wipe the junction box and the sensing head with a DAMP cloth to minimize the risk of

electrostatic discharge.

6.1

CALIBRATION MASK, GAS CYLINDER AND VOLTMETER

Calibration consists of creating a calibration atmosphere around the sensing head by injecting a reference

gas. To avoid contamination of the calibration gas by the ambient atmosphere or air draughts, always use

the calibration mask supplied by Dalemans (Figure 2 - Page 4) to inject nitrogen or calibration gas.

To apply nitrogen or calibration gas on to the detector:

1. Screw the pressure-regulator/flowmeter onto the gas cylinder and tighten the connection.

2. Undo the locking screw of the sensor housing using the 1.5 mm hexagonal key (OUT00000115).

3. Unscrew the body and top assembly of the sensor housing using the OUT00000113 spanner and

the 30 mm flat spanner (OUT00000114). The flat spanner is positioned between the base of the

sensor housing and the box.

4. Connect one end of the flexible hose to the flowmeter outlet and the other end of the flexible hose to

one of the end-fittings on the calibration mask.

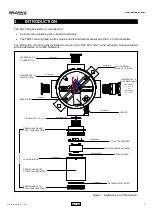

Figure 5 : Opening the FPH01 sensing head

30 mm FLAT SPANNER

OUT00000114

OUT00000113

1.5 MM HEX KEY

OUT00000115

LOCKING SCREW

SENSING HEAD

Ex