FIG. 7

KEEP THE TOOL POINTED AWAY FROM YOURSELF AND

OTHERS WHEN LOADING FASTENERS. FAILURE TO DO

COULD RESULT IN POSSIBLE SERIOUS PERSONAL INJURY.

NEVER LOAD FASTENERS WITH THE WORKPIECE

CONTACT OR TRIGGER ACTIVATED. DOING SO COULD

RESULT IN POSSIBLE SERIOUS PERSONAL INJURY.

REMOVING THE NAILS:

Disconnect air supply.

Press magazine latch and pull magazine to open

position(FIG 5).

Grasp the head of the nail strip and remove from

magazine.

1.

2.

3.

6

WARNING

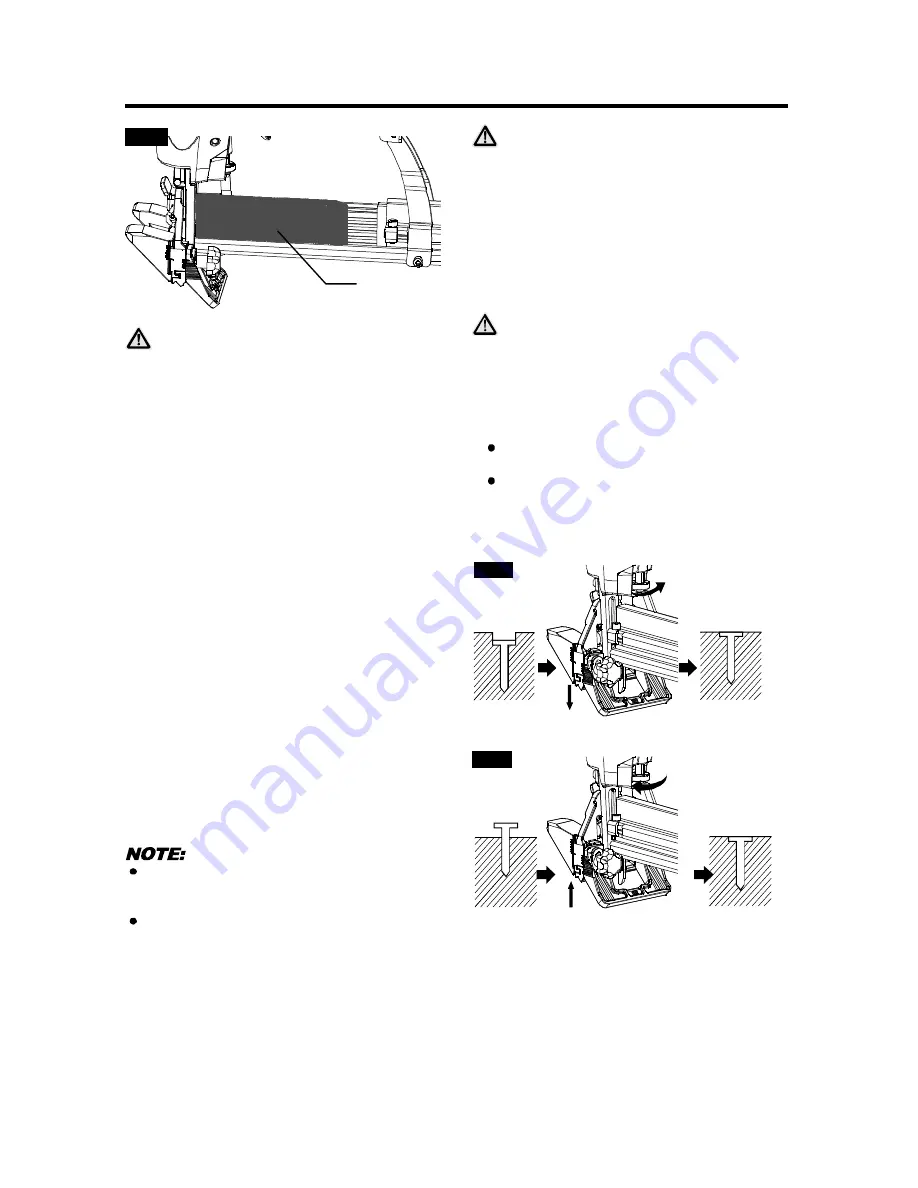

METHODS OF OPERATION

This tool is equipped with the safety and does not operate

unless the safety is depressed.

The methods of operation to drive nails with this tool is

sequential actuation mechanism.

1).Position the nail outlet on the workpiece with finger off

the trigger.

2).Depress the safety firmly until it is completely

depressed.

3).Pull the trigger to drive a nail.

4).Remove finger from the trigger.

Always handle nails and package carefully. If nails are

dropped, collating bent may be broken, which will cause

mis-feeding and jamming.

After nailing:

1).Disconnect air hose from the tool.

2).Remove all nails from the tool.

3).Supply 5-10 drops of pneumatic tool lubricant into

the air plug on the tool.

4).Open the petcock on the air compressor tank to drain

any moisture.

COLD WEATHER OPERATION

When using the tool in cold conditions the tool will cycle

slower than usual while driving the first nails. The cycle rate

will increase as the tool warms up. Keep tool warm to avoid

reduced cycle rate.

DO NOT USE A FROZEN TOOL.

Allow tool to thaw before

using. Moisture frozen in the tool may impede internal

components resulting in the risk of injury and/or tool

damage.

WARNING

To continue nailing a separate location, move the tool

along the wood, repeating steps (2-4) as required.

Staple

18Ga.

ADJUSTING THE NAILING DEPTH

Disconnect the tool from the air source before making

adjustments.

Such precautionary safety measures reduce

the risk or unintentional tool operation.

Disconnect tool from air supply.

Remove nails from the tool.

Adjust tool driving depth:

To reduce the nail depth , turn the adjustment knob

counter clockwise (FIG 8).

To drive the nail deeper, turn the adjustment knob

clockwise (FIG 9).

Reload nails as described in the "Loading Nails" section

of this manual.

Reconnect air supply.

1.

2.

3.

4.

5.

WARNING

Too Deep

Flush

Turn the adjustment knob counter clockwise

FIG. 8

Flush

Too Shallow

Turn the adjustment knob clockwise

FIG. 9

The nailer is equipped with an adjustable depth for flooring,

and available for wooden floors of different shapes. This

feature allows the user to determine how deep a fastener

will be drivned into the flooring surface.

1. Loose the screws(FIG.10,FIG.11).

2. Adjust the plastic cover to the extend desired(FIG.12).

3. Tighter the screws(FIG.13,FIG14).