OM 1239

9

www.DaikinApplied.com

CAUTION

The MicroTech III circuit board incorporates static sensitive

devices. A static charge from touching the device can damage the

electronic components. To help prevent damage during service,

use static discharge wrist straps.Static discharge wrist straps are

grounded to the heat pump chassis through a 1 Mohm resistor.

Replacing a MicroTech III

circuit board:

1 .

Connect wrist strap to unit.

2 .

Remove faulty board and place on static protected

surface.

3 .

Remove replacement board from static protected

bag.

Note: Do not touch circuit board; hold by edges.

4 .

Holding board in grounded hand, install board in

unit.

5 .

Insert faulty board in empty static bag for return.

Initial power-up

Pre start check list:

A random start delay time between 300 and 360 seconds

is generated at power up.

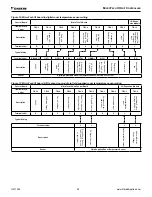

Figure 5: Location of configuration jumpers on the

MicroTech III control board

Note:

Table 6 are the settings of the hardware configuration jumpers that are read when the controller is powered.

Any changes to the jumper settings require cycling power to the controller or sending a controller a reboot

command through the network communications.

Table 6: MicroTech III controller configuration jumper settings

Baseboard Description

Jumper(s)

Jumper Setting

Function

Normal / Test Mode

JP1

Open

Normal Operation

Shorted

Service / Test Mode

Fan Operation

JP2

Open

Continuous Fan Operation (On), when not operating in the unccupied mode.

Shorted

Cycling Fan Operation (Auto)

Loop Fluid

JP3

(see warning)

Open

Water Loop Fluid - Water freeze protection (factory default setting)

Shorted

Glycol Loop Fluid - Systems with anti-freeze protection

Freeze Fault Protection

JP4

Open

None

Shorted

Freeze fault protection enabled

Room Sensor Setpoint

Potentiometer Range

JP5

Open

Short Range: -5 to +5 ºF (-2.78 to +2.78 ºC)

Shorted

Long Range: 55 to 95ºF (12.78 to 35ºC)

Thermostat / Room Sensor

JP6

Open

Thermostat Control

Shorted

Room Sensor Control

Compressor Availability

JP7 & JP8

JP7 Open

Both Compressors Available (default)

JP8 Open

JP7 Shorted

One Compressor Available

JP8 Open

JP7 Open

No Compressors Available

JP8 Shorted

WARNING

Jumper JP3 is factory provided in the open position. Extended range units require freeze protection down to 15 degrees. Jumper JP3 must

be field configured.

M

ICro

t

eCh

III u

nIt

C

ontroller