OM 1239

30 www.DaikinApplied.com

t

ypICal

W

IrIng

d

IagraMs

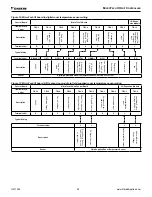

MicroTech III controller with I/O expansion module – with waterside economizer

208/230, 460, 575-60-3

COMPRESSOR

PROTECTOR

MODULE

T2

T1

S2

S1

M2

M1

COMPRESSOR

PROTECTOR

MODULE

T2

T1

S2

S1

M2

M1

LED1

SLTS

RV

LED1

GRY 46

BLU 41

BLU 40

RAT

LED2

IOEXP

COS

BLK 60

BLK 61

SEE NOTE

LED2

JP_2 JP_3 JP_4 JP_5 JP_6 JP_7 JP_8

H1

H2

N3

N2

N1

L1-3

L1-2

L1-1

H3

H5

H4

H7

H6

H8

H9

TB2

TEST-1

TB1

TB3

RUN PRG

JTAG

BLU 20

LP2

HP2

SLTS2

1

1

1

1

1

JP1

JP8

JTAG

RV2

YEL 11

RED 12

CC1

BRN 52

BRN 53

BLU 42

BLU 43

BLK 62

BLK 63

YEL 19

LP

BLK 10

YEL 8 (L2)

RED 9 (L3)

BLK 7 (L1)

R1

HP

BRN 55

BRN 54

GRN/YEL 97

FAN

MOTOR

LWT

DAT

BLK

BLU

YEL 45

BLK/RED-460V

RED-208V

ORG-230V

BLK-575V

1

JP_1

BLK 4

YEL 5

RED 6

YEL 27

BLU 28

CC2

YEL 34

BLK 33

L3

L2

L1

X2

BLK

YEL

BLU

YEL 89

BLK 81

TB2

RED

OL

T1

T2

L1

T3

L2

L3

COM

24V

X1

T1

TB1

L1

T2

L3

L2

L1

SERVICE &

DISCONNEW

L3

L2

BLK 1

YEL 2

RED 3

T3

GND

YEL 18

YEL 31

RED 32

L1

L2

L3

CM-1

BLK 30

CM-2

BLK/RED - 460V

RED - 208v

ORG - 230V

BLK - 575V

YEL

77

BLU

75

BLU

72

BLU

70

YEL

76

BLU

74

BLU

73

BLU

71

RED 35

YEL

BLU 15

YEL 14

45

2

R3

45

2

R4

87

86

TO GRY 46

10

11

85

WSE

M

EWT

COE

TO COS

R4

BLU

104

YEL

103

R3

YEL

101

BLU

102

IO Expansion Module

C - 24VAC COMMON

O - W3 - HEAT -3

G - FAN

Y1 - COOL - 1

Y2 - COOL 2

W1 - HEAT - 1

W2 - HEAT - 2

A - ALARM OUTPUT

5 - DC SIGNAL COM

4 - ROOM SENSOR/TO

3 - SETPOINT ADJUST

2 - FAN MODE/HT-CL-AUTO

1 - ROOM SENSOR LED

U - MARK IV - OCC/UNOCC

E - EMER SHTDN INPUT

R - 24VAC

Communication

Module

MicroTech III Controller

24V NO

24VAC COMMON

24V NC

Note: Switch L2/L3 fan

motor wires for

left-hand unit

Note:

Wiring diagrams are typical.

For the latest drawing version refer

to the wiring diagram located on the

inside of the controls access panel of

the unit.

Gray tinted areas in the wiring dia-

gram: Units with factory installed com-

munication module include Discharge

Air Temperature (DAT) and Return Air

Temperature (RAT) sensors shipped

loose and are field installed. The

Leaving Water Temperature (LWT)

sensor is factory installed.

Legend

Item Description

CC1

Circuit 1 Compressor Contactor

CC2

Circuit 2 Compressor Contactor

CM1

Circuit 1 Compressor

CM2

Circuit 2 Compressor

COS

Condensate Overflow Sensor

HP

Circuit 1 High Pressure Switch

HP2

Circuit 2 High Pressure Switch

IOEXP

I/O Expansion Board / Harness

LED1

LED Annunciator / Harness

LED2

LED Annunciator / Harness

*RAT

Return Air Temperature

*LWT

Leaving Water Temp Sensor

LP

Circuit 1 Low Pressure Switch

LP2

Circuit 2 Low Pressure Switch

SLTS

Circuit 1 Suction Line Temp Sensor

SLTS2

Circuit 2 Suction Line Temp Sensor

MTIII

MicroTech III Main Board

R1

Fan Motor Starter

RV

Circuit 1 Reversing Valve Solenoid

RV2

Circuit 2 Reversing Valve Solenoid

TB1

Power Terminal Block

X1

75 VA Transformer

X2

50 VA Transformer

*DAT

Discharge Air Temp Sensor

*EWT

Entering Water Temp Sensor

WSE

Waterside Economizer

TB2

Power Terminal Block

Notes: 1. “Run/Prg” Jumper to be in “Run” position for

normal operation

* Leaving Water (LWT), Discharge Air (DAT) and

Return Air Temperature (RAT) sensors are

field installed.

_ _ _ _

Denotes optional feature