Troubleshooting Guide and FAQ

OM 1085-6 • MICROTECH III CONTROLLER

BACnet Communication Module Only

The following section applies only to the BACnet MS/TP

communication module.

Light Emitting Diodes (LEDs)

The BACnet communication module has four LEDs that

indicate the status of the module, the connection to the unit

controller and/or BACnet network. These LEDs are useful for

verifying communication between the unit controller and the

network, as well as diagnosing a potential problem.

provides a description of the LED activity. For more details, see

.

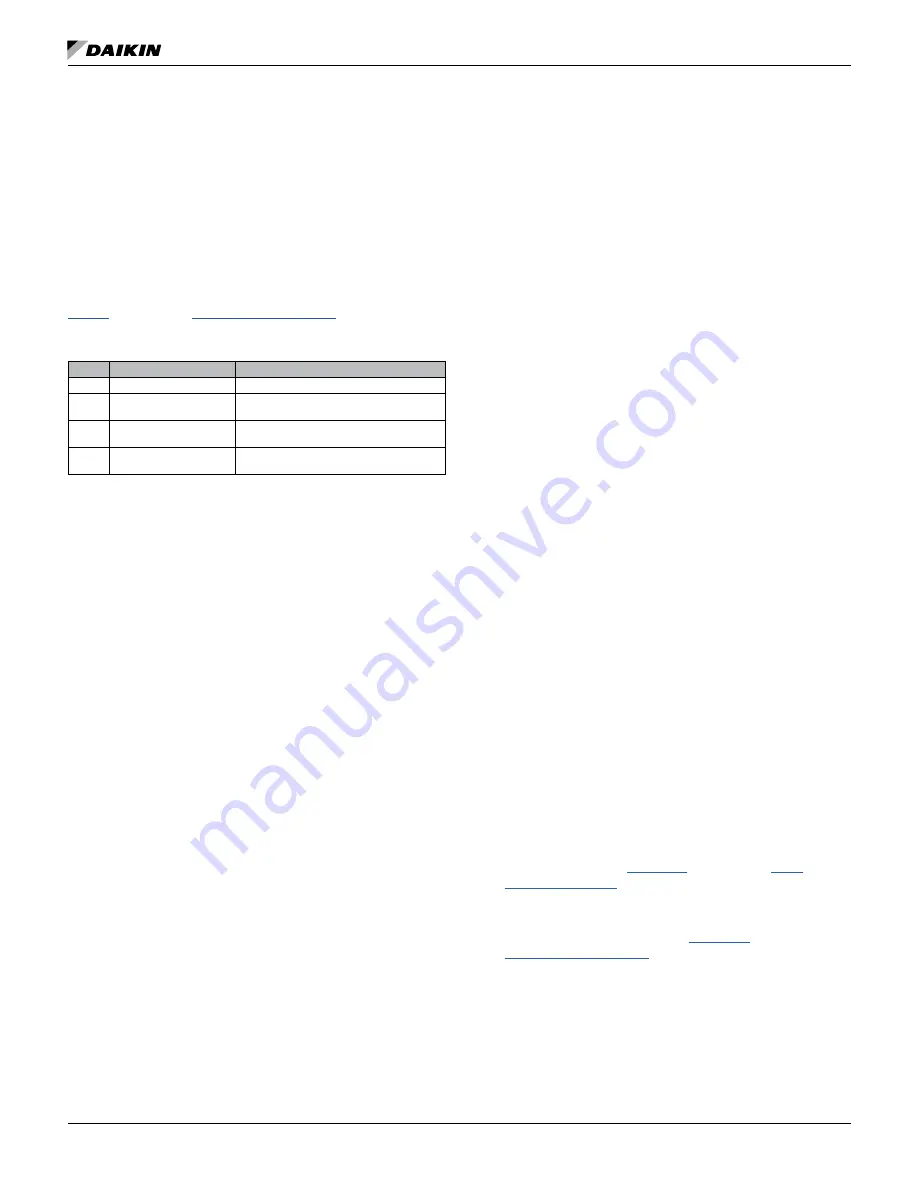

Table 17: BACnet Communication Module - LED Activity

LED

Function

Description

D1

Program Running

Program main loop activity

D2

Unit Controller Message SPI Activity, LED on during unit controller

message

D3

MS/TP Transmit

Flashes on when transmitting a MS/TP

message

D4

MS/TP Receive

Flashes on when receiving a MS/TP

message

Q:

No LEDs are lit

A:

The communication module may not be properly installed or

may not have the BACnet application software loaded.

• Remove the communication module and then reinstall

it, verifying that the connector lands on all of the pins (it

is very easy to either miss just one pin or all of the pins

even with the standoffs).

• If the communication module is properly installed, try it

on a different, functioning unit. If the LEDs still do not

function properly, replace the communication module.

• Re-download the BACnet software in the communication

module.

Contact the Controls Customer Support

group at 866-462-7829 before proceeding with this

option .

Q:

All four LEDs are lit

A:

The BACnet application software has not been properly

downloaded.

• Re-download the BACnet software in the communication

module.

• Replace the BACnet communication module.

Q:

Program LED (D1) never blinks

A:

The BACnet software is not running correctly in the

communication module.

• Re-download the BACnet software in the communication

module.

• Replace the BACnet communication module.

Q:

SPI Comm LED (D2) never blinks

A:

The communication module is not communicating with the

unit controller.

• Verify that the programming jumper on the baseboard is

in the RUN position and not the PRG position.

• Verify that unit controller is controlling the water source

heat pump unit.

• Re-download the unit controller application code.

• Re-download the BACnet software in the communication

module.

•

Install the communication module on a different,

functioning unit to determine if the problem is associated

with the unit controller or the communication module.

Q:

RX LED (D4) never blinks

A:

The communication module is not communicating with the

network.

• Verify the BACnet MS/TP settings through the serial port

on the communication module (check baud rate and any

potential addressing conflicts).

• Verify proper network wiring.

• Re-download the BACnet software in the communication

module.

• If the network settings are correct and the application

software is functioning properly, this could indicate a

hardware defect. Replace the communication module, if

necessary.

Q:

CRC errors

A:

The BAS indicates “CRC errors” at the workstation.

• Upgrade the communication module to the newest

version of BACnet software. It is not necessary to

upgrade the unit controller or I/O expansion module

software.

Q:

Communication module cannot be configured through

serial port

A:

This could be caused by an incorrect or defective cable

used to configure the communication module, software

installation error, a previous change in the serial port

settings, or potentially defective hardware.

• Verify that the communication module is connected with

a DB9 female-female (modem-modem) serial cross-over

cable. Refer to the MicroTech III WSHP Unit Controller

, available on

•

Confirm that the serial terminal device application settings

are correct. . Refer to the MicroTech III WSHP Unit

• Verify that the LED activity is normal. See

.

• Try resetting the communication module back to original

default settings.

• Re-download the BACnet software in the communication

module.

• Replace the communication module, if necessary.

Содержание MicroTech III

Страница 39: ......