E(D/B)(H/L)Q011~016BB

Unit for air to water heat pump system

4PW67904-1 – 01.2011

Installation manual

22

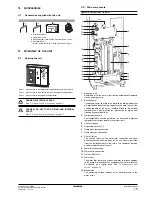

Door 2 electrical parts of the hydraulic compartment

A11P................ Main PCB

A12P................ User interface PCB (remote controller)

A3P.................. Thermostat (EKRTW*, EKRTR*)(PC=Power Circuit)

A3P.................. Solar pump station PCB (EKSR3PA)

A4P.................. Digital I/O PCB (EKRP1HB)

A4P.................. Receiver PCB (EKRTR*)

E11H,E12H...... Backup heater element 1, 2

E13H................ Backup heater element 3 (only for W1 models)

E4H.................. Booster heater

E5H.................. Switch box heater

E6H.................. Expansion vessel heater

E7H.................. Plate heat exchanger heater

F1B .................. Fuse backup heater

F1T .................. Thermal fuse backup heater

F2B .................. Fuse booster heater

FU1.................. Fuse 3.15 A T 250 V for PCB

FU2.................. Fuse 5 A T 250 V

FuS,FuR .......... Fuse 5 A 250 V for digital I/O PCB

K1M ................. Contactor backup heater step

K3M ................. Contactor booster heater

K4M ................. Pump relay

K5M ................. Contactor for backup heater all pole disconnection

M1P ................. Pump

M2S ................. 2-way valve for cooling mode

M3S ................. 3-way valve: floor heating/domestic hot water

PHC1 ............... Optocoupler input circuit

Q1DI,Q2DI....... Earth leakage circuit breaker

Q1L.................. Thermal protector backup heater

Q2L.................. Thermal protector 1 booster heater

Q3L.................. Thermal protector 2 booster heater

(only for W1 models)

R1H ................. Humidity sensor (EKRTR*)

R1T.................. Ambient sensor (EKRTW*, EKRTR*)

R2T.................. External sensor (floor or ambient) (EKRTETS)

R5T.................. Domestic hot water thermistor (EKHW*+EKHTS)

R11T................ Outlet water heat exchanger thermistor

R12T................ Outlet water backup heater thermistor

R13T................ Refrigerant liquid side thermistor

R14T................ Inlet water thermistor

S1L .................. Flow switch

S1S.................. Solar pump station relay

S1T .................. Thermostat switch box heater

S2S.................. Benefit kWh rate power supply contact

S2T .................. Thermostat expansion vessel heater

S3S.................. Dual set point 2 contact

S3T .................. Thermostat plate heat exchanger

S4S.................. Dual set point 1 contact

SS1.................. DIP switch

TR1.................. Transformer 24 V for PCB, for relays and valves

V1S,V2S .......... Spark suppression 1, 2

X1M~X11M...... Terminal strips

X2Y~X5Y,X9B.. Connector

NOTES

1.

THIS WIRING DIAGRAM ONLY APPLIES TO THE HYDROMODULE

SWITCH BOX

2.

USE A DEDICATED POWER CIRCUIT FOR THE BACKUP HEATER

AND BOOSTER HEATER. NEVER USE A POWER CIRCUIT

SHARED BY OTHER APPLIANCE.

3.

: FIELD WIRING

NO/NC

: NORMAL OPEN/NORMAL CLOSED

SPST

: SINGLE POLE SINGLE THROW

4.

: TERMINAL STRIP

: CONNECTOR

: TERMINAL

: PROTECTIVE EARTH

5.

DO NOT OPERATE THE UNIT BY SHORT-CIRCUITING ANY

PROTECTION DEVICE

6.

COLOURS:

BLK

: BLACK

PNK

: PINK

BLU

: BLUE

RED

: RED

BRN

: BROWN

VIO

: VIOLET

GRN

: GREEN

WHT

: WHITE

GRY

: GREY

YLW

: YELLOW

ORG

: ORANGE

7.

FOR *KHWSU*V3, REFER TO OPTION MANUAL

8.

FOR *KSOLHWAV1, REFER TO OPTION MANUAL

9.

MAXIMUM LOAD: 0.3 A - 250 V AC MINIMUM LOAD: 20 mA -

5 V DC

10.

230 V AC OUTPUT MAXIMUM LOAD: 0.3 A

11.

BACKUP HEATER KW REDUCTION. REFER TO INSTALLATION

MANUAL

12.

FOR BENEFIT kWh RATE POWER SUPPLY INSTALLATION, REFER

TO INSTALLATION MANUAL

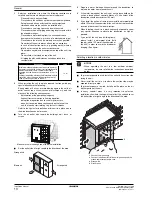

POWER SUPPLY

POWER SUPPLY

Only for benefit kWh rate

power supply installation:

use normal kWh rate

power supply for E5H,

E6H, E7H.

Only for benefit kWh rate power supply

installation: use normal kWh rate power supply

for E5H, E6H, E7H.

FROM COMPRESSOR

MODULE SWITCH BOX

FROM COMPRESSOR MODULE SWITCH

BOX

To bottom plate heater

To bottom plate heater

E5H, E6H, E7H, internally

powered (Standard)

E5H, E6H, E7H, internally powered (Standard)

POSITION OF PARTS

POSITION OF PARTS

HYDROMODULE

SWITCH BOX

HYDROMODULE SWITCH BOX

domestic hot water tank

domestic hot water tank

change-over to boiler

output

change-over to boiler output

Solar pump connection

Solar pump connection

Alarm output

Alarm output

cooling/heating on/off

output

cooling/heating on/off output

Solar input

Solar input

Standard 6 kW

Standard 6 kW

Reduced 3 kW

Reduced 3 kW

Dual set point application

(refer to installation

manual)

Dual set point application

(refer to installation manual)

3 wire type (SPST)

3 wire type (SPST)

NO valve

NO valve

NC valve

NC valve

user interface

user interface

OUTSIDE UNIT

OUTSIDE UNIT

only for... option

only for... option

electric heater fuse

electric heater fuse

*KHW* kit fuse

*KHW* kit fuse

WIRING DEPENDENT ON MODEL

FIELD WIRING

OPTION

FIELD WIRING

PCB

WIRE COLOUR