E(D/B)(H/L)Q011~016BB

Unit for air to water heat pump system

4PW67904-1 – 01.2011

Installation manual

20

7.

C

HARGING

WATER

1

Connect the water supply to a drain and fill valve (see

"5.2. Main

components" on page 10

).

2

Make sure the automatic air purge valve is open (at least

2 turns).

3

Fill with water until the manometer indicates a pressure of

approximately 2.0 bar. Remove air in the circuit as much as

possible using the air purge valves. Air present in the water

circuit might cause malfunctioning of the backup heater.

4

Check that the backup heater vessel is filled with water by

opening the pressure relief valve. Water must flow out of the

valve.

8.

P

IPING

INSULATION

The complete water circuit, inclusive all piping, must be insulated to

prevent condensation during cooling operation and reduction of the

heating and cooling capacity as well as prevention of freezing of the

outside water piping during winter time. The thickness of the sealing

materials must be at least 13 mm with 0.039 W/mK in order to

prevent freezing on the outside water piping.

If the temperature is higher than 30°C and the humidity is higher than

RH 80%, then the thickness of the sealing materials should be at

least 20 mm in order to avoid condensation on the surface of the

sealing.

9.

E

LECTRICAL

WIRING

WORK

9.1.

Precautions on electrical wiring work

INFORMATION

■

During filling, it might not be possible to remove all air

in the system. Remaining air will be removed through

the automatic air purge valves during first operating

hours of the system. Additional filling with water

afterwards might be required.

■

The water pressure indicated on the manometer will

vary depending on the water temperature (higher

pressure at higher water temperature).

However, at all times water pressure should remain

above 1 bar to avoid air entering the circuit.

■

The unit might dispose some excessive water through

the pressure relief valve.

■

Water quality must be according to EU directive

98/83 EC.

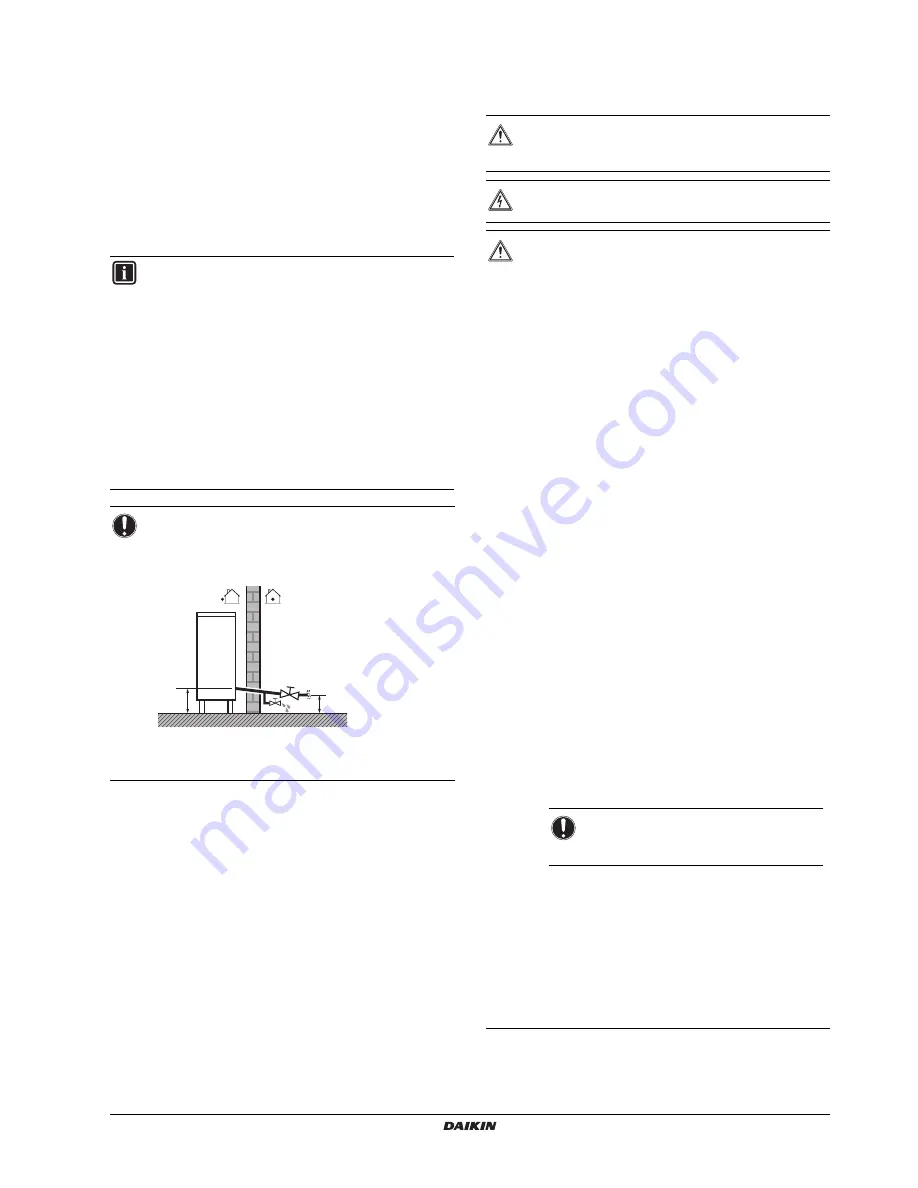

NOTICE

If no glycol is in the system in case of a power supply

failure or pump operating failure, drain the system (as

suggested in the figure below).

When water is at standstill inside the system, freezing is

very likely to happen and damaging the system in the

process.

A

<A

WARNING: Electrical installation

All field wiring and components must be installed by an

installer and must comply with the applicable legislation

DANGER: ELECTRICAL SHOCK

See

"2. General safety precautions" on page 2

.

WARNING

■

All field wiring must be carried out in accordance with

the wiring diagram supplied with the unit and the

instructions given below.

■

Electrical connections shall be made to fixed wiring.

■

A main switch or other means for disconnection,

having a contact separation in all poles, must be

incorporated in the fixed wiring in accordance with

relevant local laws and regulations.

■

Use only copper wires.

■

For W1

Make sure to connect power supply cables in normal

phase. If connected in reverse phase, the remote

controller of the unit indicates "

U1

" and the equipment

cannot operate. Change any two of the three power

supply cables (L1, L2, L3) to correct phase.

■

Never squeeze bundled cables. Secure the electrical

wiring with cable ties as shown in

figure 2

so that it

does not come into contact with the piping

(particularly on the high-pressure side) or sharp

edges.

Make sure no external pressure is applied to the

terminal connections.

■

Power supply wires must be attached securely.

■

If the power supply has a missing or wrong N-phase,

equipment will break down.

■

Be sure to establish an earth. Do not earth the unit to

a utility pipe, surge absorber, or telephone earth.

Incomplete earth may cause electrical shock.

■

Be sure to install an earth leakage circuit breaker in

accordance with the applicable legislation. Failure to

do so may cause electric shock or fire.

■

When installing the earth leakage circuit breaker

make sure that it is compatible with the inverter

(resistant to high frequency electrical noise) to avoid

unnecessary opening of the earth leakage circuit

breaker.

■

As this unit is equipped with an inverter, installing a

phase advancing capacitor not only will deteriorate

power factor improvement effect, but also may cause

capacitor abnormal heating accident due to high-

frequency waves. Therefore, never install a phase

advancing capacitor.

■

Be sure to use a dedicated power circuit; never use a

power supply shared by another appliance.

■

Be sure to install the required fuses or circuit

breakers.

NOTICE

The earth leakage circuit breaker must be a

high-speed type breaker of 30 mA (<0.1 s).