D2CND0 D2CND0 D2TND0

D2TND0 D2TND024A4AA

Wall-mounted condensing boiler

ESIE17-09 / 2017.11

Servicing manual

27

7.2

Operating The Appliance

Switching ON

Connect the appliance to the main power supply.

Press the “Mode” button for 5 seconds to switch ON the appli

-

ance. After that, you can select an operation mode by press

-

ing the Mode button shortly.

Use of the appliance is explained in following parts of this

manual.

7.2.1

Low Water Temperature Function

Low water temperature function is a safety function that takes

place at first central heating operation after each power supply

interruption and at first central heating operation after each 90

days. When this function is active, boiler operates according

to a defined set value for around 15 minutes and the icon

blinks. After this function is ended, normal operation goes

on (for details of the function refer to page 36).

7.2.2

Electronic Gas Adaptive System Calibration

Electronic gas adaptive system calibrates itself in pre-deter

-

mined time intervals. First calibration takes place just after first

burner activation after each power ON. Calibration process

duration is around 60 seconds. After calibration is ended, boil

-

er modulates to required capacity. Calibration process has no

any effect to boiler operation.

7.3

Basic use

7.3.1

Home Screen

It is the screen that is displayed after activating the LCD sc

-

reen with one of the dials or buttons. You can use the home

screen to read out settings that are meant for daily use. What

you can see on the home screen depends on your system

configuration.

The following home screens may be possible;

•

Room temperature (Daikin room thermostat connected)

•

Central Heating set temperature

•

Virtual room temperature (with Outdoor Sensor)

•

Domestic hot water set temperature

•

System Pressure (at stand-by mode)

7.3.2

Selecting Operation Mode

The operation mode can be changed by pushing the “Mode”

button.

7.4

Description of the Operation Modes

7.4.1

Stand-by Mode

In stand-by mode both central heating and domestic hot water

operation modes are disabled. The protection functions such

as frost protection are still active at standby mode. The home

-

screen shows the system pressure, as well as the icon.

7.4.2

Summer Mode

In Summer mode, only domestic hot water operation mode

is enabled. Central heating operation mode is disabled. The

boiler will only produce heat for domestic hot water.

The domestic hot water setpoint, and the icon is shown

on the home screen.

The icon blinks if domestic hot water operation is active.

7.4.3

Winter Mode

In Winter mode, domestic hot water operation mode and cen

-

tral heating operation mode are both enabled. The boiler can

produce domestic hot water, as well as produce heat for cen

-

tral heating.

The central heating temperature setpoint, and the icon,

as well as the icon are shown on the home screen. When

domestic hot water operation is active, Domestic hot water

setpoint is shown on the homescreen.

The icon blinks if domestic hot water operation is active.

The icon blinks if central heating operation is active.

7.4.4

Central Heating Only Mode

In this mode, only central heating operation mode is enabled.

The central heating temperature setpoint and the icon is

shown on the home screen.

The icon blinks if central heating operation is active.

7.4.5

Full Off Mode

In this mode both central heating and domestic hot water op

-

eration modes are disabled. In addition, LCD display will be

darkened and will not be activated with any user interaction.

The protection functions such as frost protection are still ac

-

tive at Full off mode. Full off mode is activated and deactivated

if mode button is pressed for 5 seconds while boiler is in any

mode.

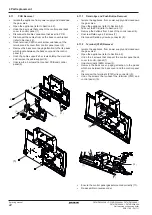

7 Operation

(5 s)

(5 s)

a

c

b

d

e

a Central heating only mode

b Standby mode

c Summer mode

d Winter mode

e Full-off mode