D2CND0 D2CND0 D2TND0

D2TND0 D2TND024A4AA

Wall-mounted condensing boiler

ESIE17-09 / 2017.11

Servicing manual

35

Explanations of parameters related with weather compen

-

sation are given in “Service parameters” and “User settings

menu” sections.

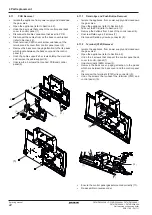

7.10.6.2 Effect of Heating Slope to CH Temperature

The effect of heating slope is illustrated on the graph below;

7.10.7 Scot Parameters (C) Safety combustion techno

-

logy system

The PCB of the appliance provides continuous control of com

-

bustion efficiency and combustion performance by means of

SCOT system. Due to SCOT system, gas valve operation is

independent of fan, so there is no need to gas valve adjust

-

ment for gas/air ratio optimization.

Ionization electrode senses a current from the flame which is

on the surface of the burner, and transmits the current to the

PCB at the level of µA.

PCB evaluates the transmitted current as a “point” value. This

value is defined as the “ion” in SCOT software.

By controlling ionization continuously, SCOT system ensures

the fuel / air mixture homogenously for each gas type.

Frequently occuring combustion and ignition

related errors can be resolved by optimizing the

parameters. C parameters are explained in detail

at following section.

INFORMATION

When the flue duct is not installed properly, SCOT

system breakdown errors occur often. Make sure

that flue duct is mounted properly on the boiler for

smooth operation.

WARNING

7.10.7.1 Detailed Explanations of C Parameters

C00:

This parameter is used to switch between fuel types. If

natural gas is to be used as supply gas, parameter must be

adjusted to “0” (zero). If LPG is to be used as supply gas, pa

-

rameter must be adjusted to “1” (one).

C01:

If a gas valve is at the limits of production tolerances,

starting gas/air ratio will be far from average value which may

also result in ignition problems (delayed or loud ignition). If

such problems are present, C02 parameter must be optimized

first. If C02 parameter change is not helping the ignition prob

-

lem, offset parameter can be the real reason. Increasing the

offset value will enrich the starting gas mixture which will help

delayed ignition problems.

7 Operation

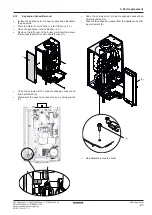

a

b

c

d

f

g

e

+

+

+

=

a Outdoor Temperature

b ODS correction P02

c Building estimation P01

d CH water temp. calculation

e Target CH water temperature

f Heating slope U01

g Virtual room temp. setpoint

(5)

(6)

(8)

(10)

(12)

(16)

(20)

(24)

(30)

10

20

0

-10

-20

-3030

40

50

60

70

80

Resultant boiler set point (ºC)

Room set point 22 (ºC)

Outside temperature (ºC)

min. (ºC)

Array of heating slopes max. (ºC)

Following parameters have impact to weather compensation

calculation:

•

•

Outdoor sensor correction (Parameter P02 )

•

Building estimation (Parameter P01)

•

Heating slope (Parameter U01)

•

Virtual room temperature set point

Calculation of CH temperature set point in principal is shown

below;

7.10.6.1 Weather compensation calculation

The required central heating temperature is calculated ac

-

cording to the outside temperature and the virtual room tem

-

perature set point, which is adjusted by left dial.

Note:

If the outside temperature falls, the central heating tem

-

perature will be increased.

SCOT PARAMETER SETTINGS

Parame-

ter No

Description

Unit

Fac-

tory

setting

Range

C00

Gas type

none 0

0 - 1

C01

Adjustment of gas

start offset

%

0

-9 - 20

C02

Adjustment of startup

capacity

%

0

-8 - 7

C03

Flue duct adjustment %

0

-5 - 10

C04

Adjustment minimum

capacity

%

0

0 - dyn.

max.

C05

Gas control offset

%

29.3

17 - 44

C06

Flame ionization

signal

pts

-

0 - 100

C07

Gas valve control

PWM

%

-

0 - 100

C08

Actual capacity value

%

-

0 - 100

C09

Ionization base value pts

-

0 - 255

C10

Minimum start ioniza

-

tion value

pts

-

0 - 255

C11

Ignition time

s

-

0 - 4.5

C12

Reducing ion base

value

pts

-

-5 - 10

C13

Reducing ion at mini

-

mum capacity

pts

-

-5 - 10

CE

Password entry

none -

0 - 999