IM 817-7

62 www.DaikinApplied.com

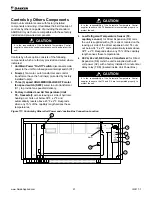

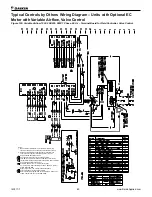

Controls by Others – Electrical

Connections

WARNING

Rigorously adhere to field wiring procedures regarding proper

lockout and tagout of components.

WARNING

To avoid electrical shock, personal injury or death:

1. Installer must be qualified, experienced technician.

2. Disconnect power supply before installation to prevent

electrical shock and damage to equipment.

3. Make all connections in accordance with electrical wiring

diagrams, and in compliance with national and local codes.

Use copper conductors only.

4. Do not exceed ratings of the device. This is a low voltage

device: Never apply more than 12VAC/VDC to any lead or

damage will result.

5. Avoid locations where excessive moisture, corrosive fumes,

or vibrations are present.

and the job-specific electrical drawings before

proceeding with field power and control wiring. See also

the wiring diagram provided on the unit ventilator right

front access panel.

Unit ventilators equipped with an optional electric

heating coil have electric heating coil power connections

at right end only.

Procedure

1 .

Provide power supply to right end compartment to

match unit nameplate.

CAUTION

Use copper conductors only. Use of aluminum conductors may

result in equipment failure and overheating hazards. All wiring in

right hand compartment must be class 1.

2 .

Wire leads provided from unit ventilator electric

connection box to load side of unit power switch

(switch provided by Daikin). The junction box has

1"(25mm) and 2"(51mm) knockouts, located 10-

1/2"(267mm) from right end of unit.

3 .

Provide ground wire from grounding screw in switch

junction box to switch ground terminal.

4 .

Wire field power supply to line side of unit power

switch. Wire ground conductor to switch ground

terminal.

5 .

Mount unit power switch in switch junction box and

install switch cover plate (provided).

6 .

On units with electric heat, the 2 pole unit power

switch is replaced by a 3 pole switch and is mounted

in the location as shown in

. (

A

) shows

switch location for valve control units and (

B

), (

C

) and

(

D

) show location for Face & Bypass control units.

(

B

) is for 208, 230 and 265 volt units. (

C

) shows

location for 460 volt units. Also, on electric heat units

with controls by others, wiring to the field mounted

controller is done in the left end compartment. See

specific wiring diagram for details. The unit comes

with wiring that requires relay controls by others

CAUTION

It is the responsibility of the Automatic Temperature Control

supplier to ensure that the proper electric heat control components

are installed, and operate correctly to protect the unit.

Figure 121: Electric Heat Unit Power Switch Locations

A

B

C

D

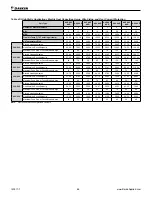

Table 41: Floor AV Electrical Data/Motor Data and Unit

Amp without Electric Heat

Unit

Series

CFM

(Nom .)

L/s

Motor

HP

Watts

Unit Current #

115V

208V

230V

265V

S07

750

354

1/4

216

2.2

1.2

1.1

1.0

S10

1000

472

1/4

277

2.8

1.6

1.4

1.3

S13

1250

590

1/4

335

3.3

1.9

1.7

1.5

S15

1500

708

1/4

445

4.4

2.6

2.3

2.0

#

Amps at unit voltage, 60 Hz, single phase

Note:

See Electric Heating on page 65, Table 40 on page

and