IM 817-4

Page 55 of 60

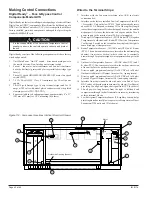

Figure 134 - Oiling Point

Figure 135 - Oiling Point for 1500 cfm units

Unit Ventilator Start-up

1. Before proceeding inspect the fan system, ensure all parts are

aligned properly and move freely. Inspect fans and fan discharge

area for obstructions. Rotate fan manually. Check that a clean filter

is installed and area in front of unit ventilator is free of debris (see

figure 124). All panels should be in place and properly fastened.

Check for outdoor air leaks and condensation. Ensure the coil section

is properly sealed using the insulating foam donuts supplied.

2. After the unit ventilator has been properly installed, activate unit

electrical power and applicable chilled water/hot water/steam/

refrigerant systems.

3. Using the applicable control, activate the unit ventilator. Depending

on the operating mode selected, the dampers, fans, and other

components should operate as needed.

4. Run the unit ventilator for ten minutes, listening and observing.

Fans should be operating correctly, and rotating in the proper

direction, without unusual noise. Likewise, the unit should be free

of sheet metal rattles and / or unusual noises. All panels should

be in place and properly fastened, and checked for air leaks and

condensation.

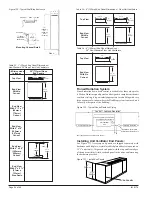

End Panel

YC-1934

End of Unit

1/4-20 Tinnerman Nut,

Clip on End Panel

1/4-20 x 1/2 Screw & 1/4 Flat Washer

1/4-20 Tinnerman Nut, Clip

Over Lower Hole in Unit

Corner Angle.

1/4-20 x 1/2 Screw & 1/4 Flat Washer

5"

Access To Fan Shaft Bearing Through Left Top Access Door

Bearing Oiler Cap

Tinnerman Clips

Tinnerman Clips

Screws

(insert through end

panel and thread into

tinnerman clips on unit

subbase)

Screws

(insert through upper mounting holes inside unit end

compartment, and thread into tinnerman clips on end panel)

End Panel w/Cut out

Figure 132 - Install End Panels With Provided Hardware

(1" End Panel Shown)

Figure 133 - Install End Panels With Provided Hardware

(6" End Panel Shown)

NOTICE

Remove debris, dust, dirt, and any obstruction from the area in

front of the return air intake grille at the floor as this will affect

unit performance. If a draftstop system has been installed be

sure that all draftstop intake grilles are unobstructed.

NOTICE

CAUTION

For 1500 cfm units, access to the fan shaft bearing is through

the center front panel. It is located between the third and fourth

fan housing from the right (Figure 135).

NOTICE

1. Position (YC-1934) bracket on wall so angle is 5" from end of unit

and near bottom (see figure 133).

2. Mark and drill required hole for fastening device (not included).

3. Attach bracket to wall.

4. Attach end panel. Bracket should prevent movement of end panel

toward end of unit when pressure is applied to end panel, readjust

bracket if necessary.

Prepare Unit Ventilator(s) for Start-up

Oiling the Fan Shaft End Bearing:

Do not attempt to operate the unit fans until the fan bearings

have been oiled. Oiled bearings provide smooth, and quiet

operation of the fan system.

See Figure 134 for oiling point. Access to fan shaft bearing is through

left top access door (750, 1000, 1250 cfm units only). Lift the oiler

cap. Oil, using a few drops of high grade SAE 20 or 30 nondetergent

oil. Do not over-oil.

G.E. motor manufacturer recommends not oiling the fan motor.

Bearing Oiler Cap