S0309000

Page 9

Standard Torques

TORQUE WRENCH EXTENSION TOOLS

Very large diameter, high grade fasteners (nuts, bolts, cap screws, etc.) require a great deal of turning

force to achieve recommended tightening torque values.

Common problems that could occur as a result are:

•

Recommended torque exceeds the measuring capacity of the torque wrench.

•

Specialized sockets do not fit the adapter on the front end (nose) of the torque wrench.

•

Generating adequate force on the back end (handle) of the wrench is difficult or impossible.

•

Restricted access or an obstruction may make use of the torque wrench impossible.

•

A unique application requires fabrication of an adapter or other special extension.

Most standard torque wrenches can be adapted to suit any one of the proceeding needs or situations, if

the right extension tool is used or fabricated.

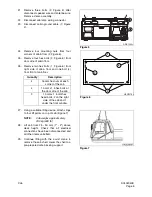

TORQUE MULTIPLICATION

A wrench extension tool can be used to

increase the tightening force on a high capacity

nut or bolt.

For example, doubling the distance between the

bolt and the back (handle) end of the torque

wrench doubles the tightening force on the bolt.

It also halves the indicated reading on the scale

or dial of the torque wrench. To accurately

adjust or convert indicated scale or dial

readings, use the following formula:

I = A x T / A + B where:

I = Indicated force shown on the torque wrench

scale or dial.

T = Tightening force applied to the nut or bolt (actual Torque).

A = Length of the torque wrench (between the center of the nut or bolt and the center of the handle).

B = Length of the extension.

As an example, if a 12" extension is added to a 12" torque wrench, and the indicated torque on the dial

reads "150 ft lb," the real force applied to the bolt is 300 ft lb:

NOTE:

The formula assumes that there is no added deflection or "give" in the joint between the

extension and torque wrench. Readings may also be inaccurate:

•

If the extension itself absorbs some of the tightening force and starts to bend or bow out.

•

If an extension has to be fabricated that is not perfectly straight (for example, an extension

made to go around an obstruction, to allow access to a difficult to tighten fastener), the

materials and methods used must be solid enough to transmit full tightening torque.

I =

A x T

=

12 x 300

=

3600

= 150

A + B

12 + 12

24

Figure 1

Содержание Solar 225LC-V

Страница 2: ......

Страница 4: ......

Страница 7: ...1SAFETY ...

Страница 8: ......

Страница 46: ...S0102000 Page 38 Track Excavator Safety ...

Страница 47: ...1SPECIFICATIONS ...

Страница 48: ......

Страница 54: ...S0205015K Page 6 Specifications for Solar 225LC V Return to Master Table of Contents ...

Страница 70: ...S0205015K Page 22 Specifications for Solar 225LC V Return to Master Table of Contents ...

Страница 71: ...1GENERAL MAINTENANCE ...

Страница 72: ......

Страница 86: ...S0302000 Page 14 General Maintenance Procedures ...

Страница 99: ...1UPPER STRUCTURE ...

Страница 100: ......

Страница 102: ...S0402040K Page 2 Cab TABLE OF CONTENTS Removal 3 Installation 6 ...

Страница 110: ...S0403050K Page 2 Counterweight Return to Master Table of Contents TABLE OF CONTENTS General 3 Removal 5 Installation 7 ...

Страница 116: ...S0403050K Page 8 Counterweight Return to Master Table of Contents ...

Страница 140: ...S0407000 Page 6 Swing Bearing ...

Страница 165: ...1LOWER STRUCTURE AND CHASSIS ...

Страница 166: ......

Страница 190: ...S0505030 Page 24 Track Assembly Return to Master Table of Contents 7 Tighten plug 1 Figure 49 Figure 49 ...

Страница 192: ...S0505030 Page 26 Track Assembly Return to Master Table of Contents ...

Страница 193: ...1ENGINE AND DRIVE TRAIN ...

Страница 194: ......

Страница 205: ...S0605060K Page 11 Air Conditioner Face and Defroster ARS1300L Figure 12 ...

Страница 229: ...S0609000 Page 9 Drive Coupling Main Pump Figure 10 DRIVE COUPLING INSTALLATION UCHIDA PUMP ...

Страница 234: ...S0609000 Page 14 Drive Coupling Main Pump ...

Страница 235: ...1HYDRAULICS ...

Страница 236: ......

Страница 249: ...S0702170K Page 13 Hydraulic System Troubleshooting Testing and Adjustment ...

Страница 272: ...S0702170K Page 36 Hydraulic System Troubleshooting Testing and Adjustment ...

Страница 274: ...S0703010K Page 2 Accumulator TABLE OF CONTENTS General Description 3 Specifications 4 ...

Страница 297: ...S0705000 Page 9 Cylinders ...

Страница 301: ...S0705000 Page 13 Cylinders ...

Страница 311: ...S0705000 Page 23 Cylinders ...

Страница 312: ...S0705000 Page 24 Cylinders SLIPPER SEAL JIG ARS4770L A 2 A A 14 B B 40 5 R 1 0 R1 1 0 Figure 10 ...

Страница 315: ...S0705000 Page 27 Cylinders ...

Страница 316: ...S0705000 Page 28 Cylinders SLIPPER SEAL STRAIGHTENING JIG ARS4780L 2 R1 50 25 100 A 15 A 2 5 R 2 C 1 Figure 11 ...

Страница 324: ...S0705000 Page 36 Cylinders 17 Force out pin bushing 1 from body of cylinder Figure 28 ...

Страница 328: ...S0705000 Page 40 Cylinders ...

Страница 335: ...S0707200 Page 7 Swing Motor Return to Master Table of Contents ...

Страница 336: ...S0707200 Page 8 Swing Motor Return to Master Table of Contents PARTS LIST Model Solar 250LC V 255LC V Figure 4 ...

Страница 341: ...S0707200 Page 13 Swing Motor Return to Master Table of Contents SPECIAL TOOLS Figure 6 ...

Страница 358: ...S0707200 Page 30 Swing Motor Return to Master Table of Contents ...

Страница 368: ...S0707330 Page 10 Travel Motor With Gearbox GM35VL Return to Master Table of Contents TRAVEL MOTOR PARTS LIST Figure 12 ...

Страница 424: ...S0708320 Page 12 Main Pump With Regulator Return to Master Table of Contents PARTS LIST Main Pump Figure 13 ...

Страница 426: ...S0708320 Page 14 Main Pump With Regulator Return to Master Table of Contents Pump Regulator Figure 14 ...

Страница 432: ...S0708320 Page 20 Main Pump With Regulator Return to Master Table of Contents Model SOLAR 225LC V BBS0030L Figure 16 ...

Страница 452: ...S0708320 Page 40 Main Pump With Regulator Return to Master Table of Contents ...

Страница 458: ...S0709401K Page 6 Main Control Valve Kayaba Figure 1 ...

Страница 459: ...S0709401K Page 7 Main Control Valve Kayaba Figure 2 ...

Страница 461: ...S0709401K Page 9 Main Control Valve Kayaba ...

Страница 463: ...S0709401K Page 11 Main Control Valve Kayaba Figure 4 ...

Страница 475: ...S0709401K Page 23 Main Control Valve Kayaba Figure 16 ...

Страница 508: ...S0709401K Page 56 Main Control Valve Kayaba Figure 54 ...

Страница 558: ...S0792105K Page 4 Hydraulic Schematic Solar 225LC V 225NLC V Return to Master Table of Contents SOLAR 225LC V Figure 2 ...

Страница 559: ...S0792105K Page 5 Hydraulic Schematic Solar 225LC V 225NLC V Return to Master Table of Contents BBS0070L SOLAR 225LC V ...

Страница 560: ...S0792105K Page 6 Hydraulic Schematic Solar 225LC V 225NLC V Return to Master Table of Contents SOLAR 225NLC V Figure 3 ...

Страница 561: ...S0792105K Page 7 Hydraulic Schematic Solar 225LC V 225NLC V Return to Master Table of Contents BDS0110L SOLAR 225NLC V ...

Страница 562: ...S0792105K Page 8 Hydraulic Schematic Solar 225LC V 225NLC V Return to Master Table of Contents ...

Страница 563: ...1ELECTRICAL SYSTEM ...

Страница 564: ......

Страница 618: ...S0802220K Page 54 Electrical System ...

Страница 637: ...S0802220K Page 73 Electrical System ...

Страница 644: ...S0892105K Page 4 Electrical Schematic Solar 225LC V 225NLC V Return to Master Table of Contents SOLAR 225LC V Figure 2 ...

Страница 647: ...S0892105K Page 7 Electrical Schematic Solar 225LC V 225NLC V Return to Master Table of Contents BDS0190L S225NLC V ...

Страница 648: ...S0892105K Page 8 Electrical Schematic Solar 225LC V 225NLC V Return to Master Table of Contents ...

Страница 649: ...1ATTACHMENTS ...

Страница 650: ......

Страница 665: ...S0904015K Page 7 Bucket 5 Roll the new O ring 1 Figure 9 into the O ring groove BBO0022L 1 Figure 9 ...

Страница 670: ......