S0205015K

Page 18

Specifications for Solar 225LC-V

Return to Master Table of Contents

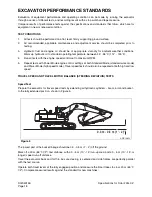

EXCAVATOR PERFORMANCE STANDARDS

Evaluation of equipment performance and operating condition can be made by running the excavator

through a series of different tests, and recording results with a stop watch and tape measure.

Compare results of performance tests against the specifications and standards that follow, which are for

equipment in new or renewed condition.

TEST CONDITIONS

1.

All tests should be performed on a flat, level, firmly supporting ground surface.

2.

All recommended, applicable maintenance and adjustment service should be completed prior to

testing.

3.

Hydraulic fluid and engine oil should be of appropriate viscosity for ambient weather conditions.

Warm up hydraulic oil to standard operating temperature, between 45° - 55°C (112° - 135°F).

4.

Run all tests with the engine speed control set to maximum RPM.

5.

Repeat tests with Power Mode engine control settings at both Standard Mode (standard work mode)

and Power Mode (high speed mode). Travel speed tests should also be repeated at both high and low

speed.

TRAVEL SPEED AND TRAVEL MOTOR BALANCE (STEERING DEVIATION) TESTS

Speed Test

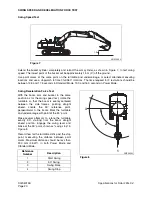

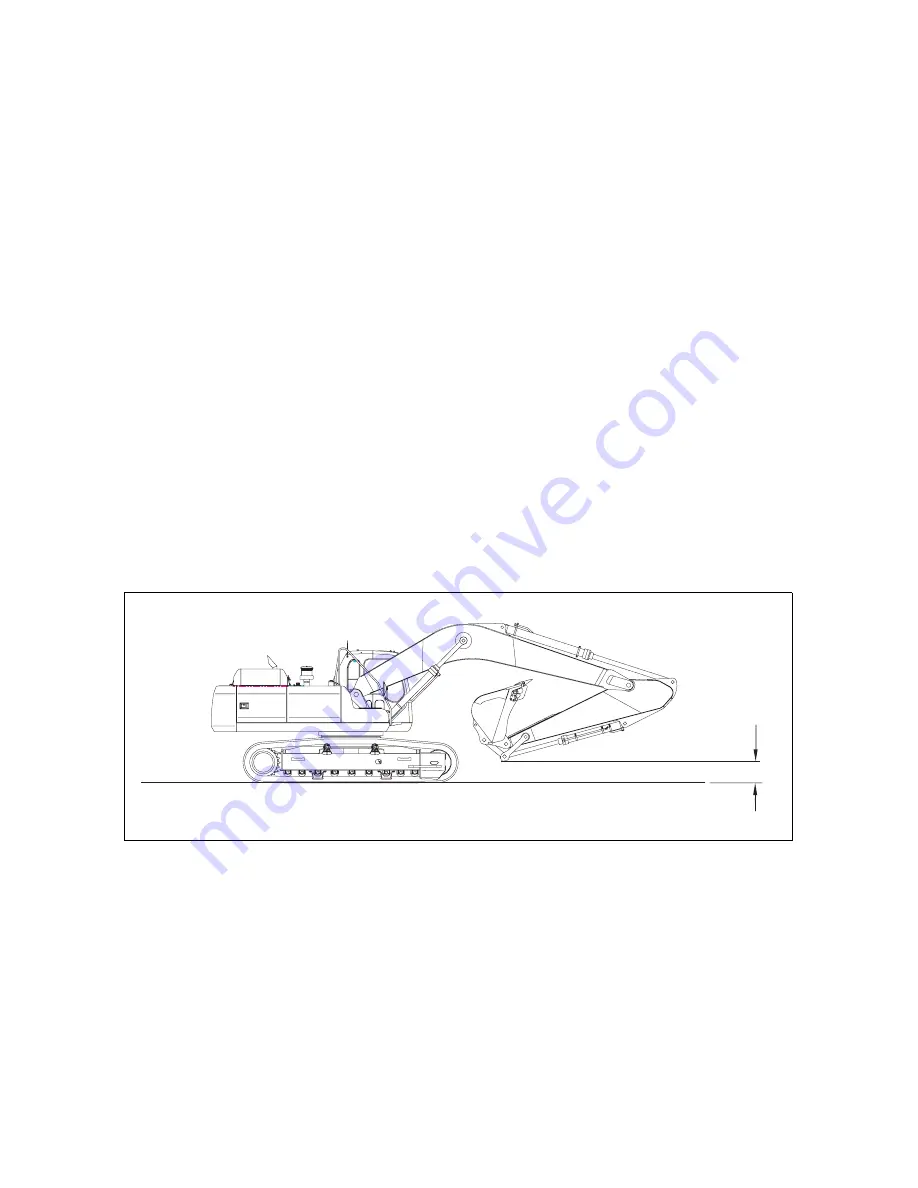

Prepare the excavator for travel speed tests by extending all hydraulic cylinders - boom, arm and bucket -

to the fully extended position, shown in Figure 5.

The lowest part of the bucket linkage should be 0.3 - 0.5 m (1' - 2') off the ground.

Mark off a 20 m (65' 7-1/2") test distance, with a 3 - 5 m (10' - 15') run-up area, and a 3 - 5 m (10' - 15', or

longer) speed run-off distance.

Travel the excavator back and forth to be sure steering is centered and side frames are perfectly parallel

with the test course.

Operate both travel levers at the fully engaged position and measure the time it takes to cross 20 m (65' 7-

1/2"). Compare measured results against the standard for new machines:

0.3 m - 0.5 m (1' - 2')

ARS1480L

Figure 5

Содержание Solar 225LC-V

Страница 2: ......

Страница 4: ......

Страница 7: ...1SAFETY ...

Страница 8: ......

Страница 46: ...S0102000 Page 38 Track Excavator Safety ...

Страница 47: ...1SPECIFICATIONS ...

Страница 48: ......

Страница 54: ...S0205015K Page 6 Specifications for Solar 225LC V Return to Master Table of Contents ...

Страница 70: ...S0205015K Page 22 Specifications for Solar 225LC V Return to Master Table of Contents ...

Страница 71: ...1GENERAL MAINTENANCE ...

Страница 72: ......

Страница 86: ...S0302000 Page 14 General Maintenance Procedures ...

Страница 99: ...1UPPER STRUCTURE ...

Страница 100: ......

Страница 102: ...S0402040K Page 2 Cab TABLE OF CONTENTS Removal 3 Installation 6 ...

Страница 110: ...S0403050K Page 2 Counterweight Return to Master Table of Contents TABLE OF CONTENTS General 3 Removal 5 Installation 7 ...

Страница 116: ...S0403050K Page 8 Counterweight Return to Master Table of Contents ...

Страница 140: ...S0407000 Page 6 Swing Bearing ...

Страница 165: ...1LOWER STRUCTURE AND CHASSIS ...

Страница 166: ......

Страница 190: ...S0505030 Page 24 Track Assembly Return to Master Table of Contents 7 Tighten plug 1 Figure 49 Figure 49 ...

Страница 192: ...S0505030 Page 26 Track Assembly Return to Master Table of Contents ...

Страница 193: ...1ENGINE AND DRIVE TRAIN ...

Страница 194: ......

Страница 205: ...S0605060K Page 11 Air Conditioner Face and Defroster ARS1300L Figure 12 ...

Страница 229: ...S0609000 Page 9 Drive Coupling Main Pump Figure 10 DRIVE COUPLING INSTALLATION UCHIDA PUMP ...

Страница 234: ...S0609000 Page 14 Drive Coupling Main Pump ...

Страница 235: ...1HYDRAULICS ...

Страница 236: ......

Страница 249: ...S0702170K Page 13 Hydraulic System Troubleshooting Testing and Adjustment ...

Страница 272: ...S0702170K Page 36 Hydraulic System Troubleshooting Testing and Adjustment ...

Страница 274: ...S0703010K Page 2 Accumulator TABLE OF CONTENTS General Description 3 Specifications 4 ...

Страница 297: ...S0705000 Page 9 Cylinders ...

Страница 301: ...S0705000 Page 13 Cylinders ...

Страница 311: ...S0705000 Page 23 Cylinders ...

Страница 312: ...S0705000 Page 24 Cylinders SLIPPER SEAL JIG ARS4770L A 2 A A 14 B B 40 5 R 1 0 R1 1 0 Figure 10 ...

Страница 315: ...S0705000 Page 27 Cylinders ...

Страница 316: ...S0705000 Page 28 Cylinders SLIPPER SEAL STRAIGHTENING JIG ARS4780L 2 R1 50 25 100 A 15 A 2 5 R 2 C 1 Figure 11 ...

Страница 324: ...S0705000 Page 36 Cylinders 17 Force out pin bushing 1 from body of cylinder Figure 28 ...

Страница 328: ...S0705000 Page 40 Cylinders ...

Страница 335: ...S0707200 Page 7 Swing Motor Return to Master Table of Contents ...

Страница 336: ...S0707200 Page 8 Swing Motor Return to Master Table of Contents PARTS LIST Model Solar 250LC V 255LC V Figure 4 ...

Страница 341: ...S0707200 Page 13 Swing Motor Return to Master Table of Contents SPECIAL TOOLS Figure 6 ...

Страница 358: ...S0707200 Page 30 Swing Motor Return to Master Table of Contents ...

Страница 368: ...S0707330 Page 10 Travel Motor With Gearbox GM35VL Return to Master Table of Contents TRAVEL MOTOR PARTS LIST Figure 12 ...

Страница 424: ...S0708320 Page 12 Main Pump With Regulator Return to Master Table of Contents PARTS LIST Main Pump Figure 13 ...

Страница 426: ...S0708320 Page 14 Main Pump With Regulator Return to Master Table of Contents Pump Regulator Figure 14 ...

Страница 432: ...S0708320 Page 20 Main Pump With Regulator Return to Master Table of Contents Model SOLAR 225LC V BBS0030L Figure 16 ...

Страница 452: ...S0708320 Page 40 Main Pump With Regulator Return to Master Table of Contents ...

Страница 458: ...S0709401K Page 6 Main Control Valve Kayaba Figure 1 ...

Страница 459: ...S0709401K Page 7 Main Control Valve Kayaba Figure 2 ...

Страница 461: ...S0709401K Page 9 Main Control Valve Kayaba ...

Страница 463: ...S0709401K Page 11 Main Control Valve Kayaba Figure 4 ...

Страница 475: ...S0709401K Page 23 Main Control Valve Kayaba Figure 16 ...

Страница 508: ...S0709401K Page 56 Main Control Valve Kayaba Figure 54 ...

Страница 558: ...S0792105K Page 4 Hydraulic Schematic Solar 225LC V 225NLC V Return to Master Table of Contents SOLAR 225LC V Figure 2 ...

Страница 559: ...S0792105K Page 5 Hydraulic Schematic Solar 225LC V 225NLC V Return to Master Table of Contents BBS0070L SOLAR 225LC V ...

Страница 560: ...S0792105K Page 6 Hydraulic Schematic Solar 225LC V 225NLC V Return to Master Table of Contents SOLAR 225NLC V Figure 3 ...

Страница 561: ...S0792105K Page 7 Hydraulic Schematic Solar 225LC V 225NLC V Return to Master Table of Contents BDS0110L SOLAR 225NLC V ...

Страница 562: ...S0792105K Page 8 Hydraulic Schematic Solar 225LC V 225NLC V Return to Master Table of Contents ...

Страница 563: ...1ELECTRICAL SYSTEM ...

Страница 564: ......

Страница 618: ...S0802220K Page 54 Electrical System ...

Страница 637: ...S0802220K Page 73 Electrical System ...

Страница 644: ...S0892105K Page 4 Electrical Schematic Solar 225LC V 225NLC V Return to Master Table of Contents SOLAR 225LC V Figure 2 ...

Страница 647: ...S0892105K Page 7 Electrical Schematic Solar 225LC V 225NLC V Return to Master Table of Contents BDS0190L S225NLC V ...

Страница 648: ...S0892105K Page 8 Electrical Schematic Solar 225LC V 225NLC V Return to Master Table of Contents ...

Страница 649: ...1ATTACHMENTS ...

Страница 650: ......

Страница 665: ...S0904015K Page 7 Bucket 5 Roll the new O ring 1 Figure 9 into the O ring groove BBO0022L 1 Figure 9 ...

Страница 670: ......