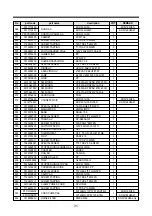

31

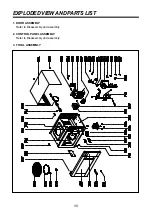

No

part code

part name

description

Q'TY

REMAKR

A00

3511710430

DOOR AS

KOR-164H0A

1

KOR-164H0A

3511710440

KOR-164H9A10

KOR-164H9A27

B00

PKCPSWKN00

CONTROL PANEL AS

KOR-161H0A

1

F01 3510802400 CABINET

PCM

T0.6

1

F02

7112401011

SCREW TAPPING

T1 TRS 4*10 MFZN

3

F03

7122401211

SCREW TAPPING

T2S TRS 4*12 MFZN

1

F04

7112403011

SCREW TAPPING

T1 TRS 4*30 MFZN

2

F05

3963822720

MOTOR SAHDED POLE

120V 60Hz MW15XA-K04

1

F06 3512514200 GUIDE

WIND

PP

1

F07 3511800500 FAN

PP

GF20

1

F08

3513003200

HOLDER CAPACITOR

SECC T0.6

1

F09

7S422X4081

SPECIAL SCREW

TT2 TRS 5*8 SE MFZN

1

F10

3518400400

DIODE HV

HVR-1X-3AB 12KV #187

1

F11

3518302200

CAPACITOR HV

2100VAC 0 .98UF #187

1

F12

3513601500

LAMP

BL 125V 25W T25 C5A H187

1

F13 3513815900 LOCK

PP

1

F14

4415A17352

SW MICRO

VP-533A-OF SPNO #187 200G

1

F15 4415A66910 SW

MICRO

VP-531A-OF/SZM-V16-FA-6

1

F16

4415A17352

SW MICRO

VP-533A-OF SPNO #187 200G

1

F17 4415A66910

SW

MICRO

VP-531A-OF/SZM-V16-FA-6

1

F18 3513702600 LEVER

LOCK

POM

1

F19

3512714600

HARNESS MAIN

KOR-161H0A

1

KOR-164H0A

3512714601

KOR-161H0A FILTER

KOR-164H9A27

F20

3516003800

SPECIAL SCREW

T2 FLANGE 5*8 MFZN

1

F21 3518002900 MAGNETRON

2M218J(MF)P

1

F22 3510311800 BASE

SBHG

T0.8

1

F23

3516003700

SPECIAL SCREW

TT3 HEX 4*9 FLG MFZN

4

F24 3518113800 TRANS

HV

DY-N95A0-16T

1

F25

7121400611

SCREW TAPPING

T2S PAN 4*6 MFZN

1

F26

3966820200

MOTOR SYNCRO

120V 2W GM-16-12F17

1

F27 3513003400 HOLDER

THERMOSTAT

PBT

1

F28

3518905300

THERMOSTAT

OFF : 75 ON : 65 H #187 NB

1

F29 3512101400 FOOT

DASF-310

4

F30

7112401011

SCREW TAPPING

T1 TRS 4*10 MFZN

5

F31

7S422X4081

SPECIAL SCREW

TT2 TRS 4*8 SE MFZN

1

F32

3515202800

STOPPER HINGE UNDER AS

KOR-121M0A

1

F33 3517400620 COUPLER

ZAREC

1

F34 3514700710 ROLLER

TEFLON

3

F35 3512517200 GUIDE

ROLLER

PP

1

F36 4419W88004 TRAY

GLASS

1350G

1

F37

3515202900

STOPPER HINGE TOP AS

KOR-121M0A

1

F38

3511403200

COVER WAVE GUIDE

HEATPROOF PP

1

F39

3516003700

SPECIAL SCREW

TT3 HEX 4*8 FLG MFZN

2

F40

3516109800

CAVITY

AS KOR-161H0A 1

F41

7122401211

SCREW TAPPING

T2S TRS 4*12 MFZN

2

F42

7122401211

SCREW TAPPING

T2S TRS 4*12 MFZN

1

F43

4413A90012

CLAMP POWER CORD

NYLON 66

1

F44

7112401011

SCREW TAPPING

T1 TRS 4*10 MFZN

1

F45

35113U6W0L

CORD POWER AS

3X14AWG 120*120 120-RTML

1

KOR-164H0A

35113UANT5

3X14AWG 60*60 120-RTML

KOR-164H9A27

F46

3518606840

NOISE-FILTER

DWEF-M29

1

KOR-164H0A only

Содержание KOR-164H0A

Страница 5: ...4 EXTERNAL VIEW 1 OUTER DIMENSION ...

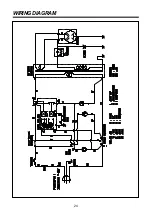

Страница 25: ...24 WIRING DIAGRAM ...

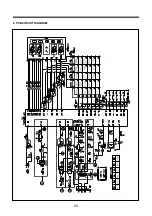

Страница 27: ...26 ...

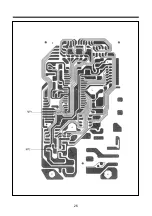

Страница 29: ...28 2 PCB CIRCUIT DIAGRAM ...