Maintenance Section

-163-

5.

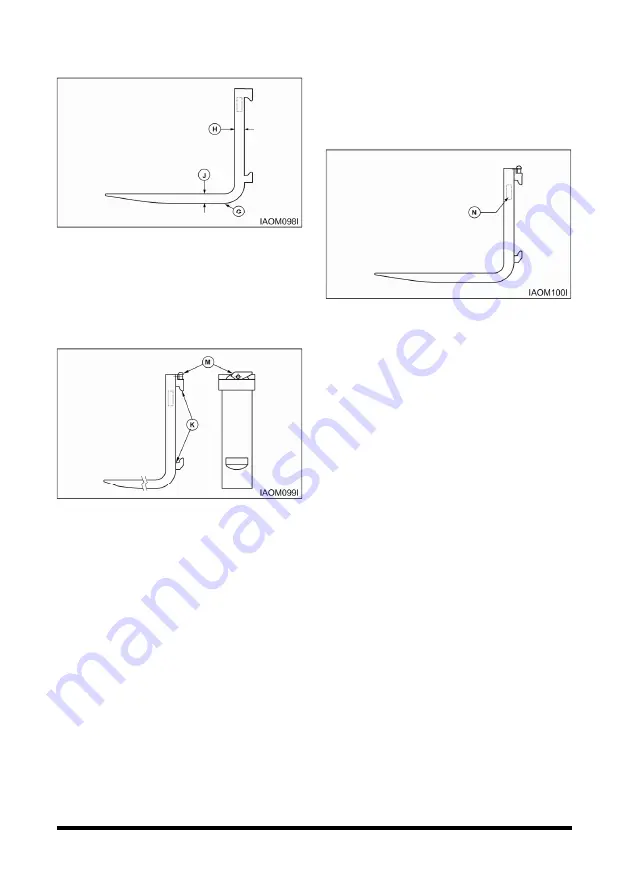

Check the fork blade (J) and shank (H) for wear with

special attention to the heel (G). The fork should be

withdrawn from service if the thickness is reduced to

90 percent or less of the original thickness.

Fork blade length may also be reduced by wear,

especially on tapered forks and platens. Remove the

forks from service when the blade length is no

longer adequate for the intended loads.

6.

Check the fork mountings (K) for wear, crushing and

other local deformation, which can cause excessive

side to side wobble of the forks. Excessive

clearance on hook type forks may allow them to fall

from the carrier. Forks which show visible signs of

such damage should be removed from service.

7.

Check the positioning lock and other fork retention

devices to make sure they are in place and working.

Hook type forks use a spring loaded pin (M),

located in the top hook, to engage notches in the

top carriage bar to hold the fork in place.

When adjusting the fork spacing, the forks are

prevented from sliding off the end of the carriage by

stop blocks. These stop blocks are at both ends of

the carriage and in the path of the bottom fork hook.

The load backrest extension may be used in place

of the stop blocks in some cases.

Shaft mounted forks may use set collars or spacers

on the shaft to either side of the fork. They may

also use U bolts, pins, or similar devices which

engage the fork through the top structure of the

carriage.

8.

Check fork markings (N) for legibility. Renew

markings as required to retain legibility.

9. a.

Lift the mast and operate the tilt control lever, until

the top surface of the forks is parallel with the

floor. Place two straight bars that are the same

width as the carriage, across the forks as shown.

b.

Measure the distance from the bottom of each

end of the two bars to the floor. The forks must

be parallel within 3 mm (.12 in) for Full Tapered

and Polished (FTP) forks, all other forks 6.4 mm

(.25 in), for their complete length.

c.

Put one fork, one third from the tip, under a

fixture that will not move. Then operate the tilt

control with caution until the rear of the truck lifts

just off the floor. Follow the same procedure

with the second fork. Repeat Step a.

Содержание D35S-2

Страница 31: ...Safety Section 29 Lean away from the direction of fall Lean forward...

Страница 39: ...General Section 37 Capacity Chart...

Страница 40: ...General Section 38 Capacity Chart...

Страница 41: ...General Section 39 Capacity Chart with Side Shifter...

Страница 42: ...General Section 40 Capacity Chart with Side Shifter...

Страница 43: ...General Section 41 Capacity Chart...

Страница 44: ...General Section 42 Capacity Chart...

Страница 45: ...General Section 43 Capacity Chart with Side Shifter...

Страница 46: ...General Section 44 Capacity Chart with Side Shifter...

Страница 47: ...General Section 45 Capacity Chart D G 50C 2...

Страница 48: ...General Section 46 Capacity Chart with Side Shifter D G 50C 2...