RADIANT PANEL OR OTHER “LOW TEMPERATURE” SYSTEM

The First Hour Ratings published in this manual are based on a boiler supply temperature of 180F. If, for

any reason, the boiler water temperature going to the heating system is held to levels under 180F, special piping

is needed to provide boiler water to both the Maxi-Therm and the heating system at the proper temperatures.

Two ways of doing this are with a heat exchanger or a 4-way valve.

In either system, the Maxi-Therm must be connected to the boiler before any means are used to control the

temperature of the water going to the system. The temperature of the water going through the Maxi-Therm coil

is thus limited only by the boiler high limit setting, which should be set at 180F or higher.

Figure 9 illustrates the use of a heat exchanger to control the temperature of the water going to the “low

temperature” system. The low temperature system water is completely isolated from the water passing through

the boiler and Maxi-Therm. For this reason, the low temperature system must be equipped with its own

expansion tank, fill, and air removal apparatus. The temperature in this system may be controlled through the

use of an aquastat in the low temperature side.

Figure 10 illustrates the use of a 4-way valve to control maximum heating zone temperature while allowing

180F boiler water to enter the Maxi-Therm zone. The four way valve may be manually set to provide the

maximum allowable temperature to the heating zone or it may be provided with a motor to control the valve in

response to some parameter (outdoor temperature for example).

MAXI-THERM MANIFOLD PIPING (BOILER SIDE)

Multiple Maxi-Therm installations must be done in the “reverse-return” manner illustrated in Figure 11. The

reason for this is to create the same pressure drop (and therefore the same flow) through the coil of each Maxi-

Therm. The boiler manifold piping must be sized so that each coil has the flow rate called for in Table 1. For

example, if two MT040G’s are to be manifold together, the circulator and zone piping common to both tanks

must be capable of moving 16 GPM (2 x 8 GPM)

Because the pressure drop through Maxi-Therm coils varies from size to size, it is hard to predict the flow

rate that will be developed through each coil when two Maxi-Therms of different sizes are placed in the same

manifold. For this reason it is best not to mix Maxi-Therms of two different sizes in the same zone.

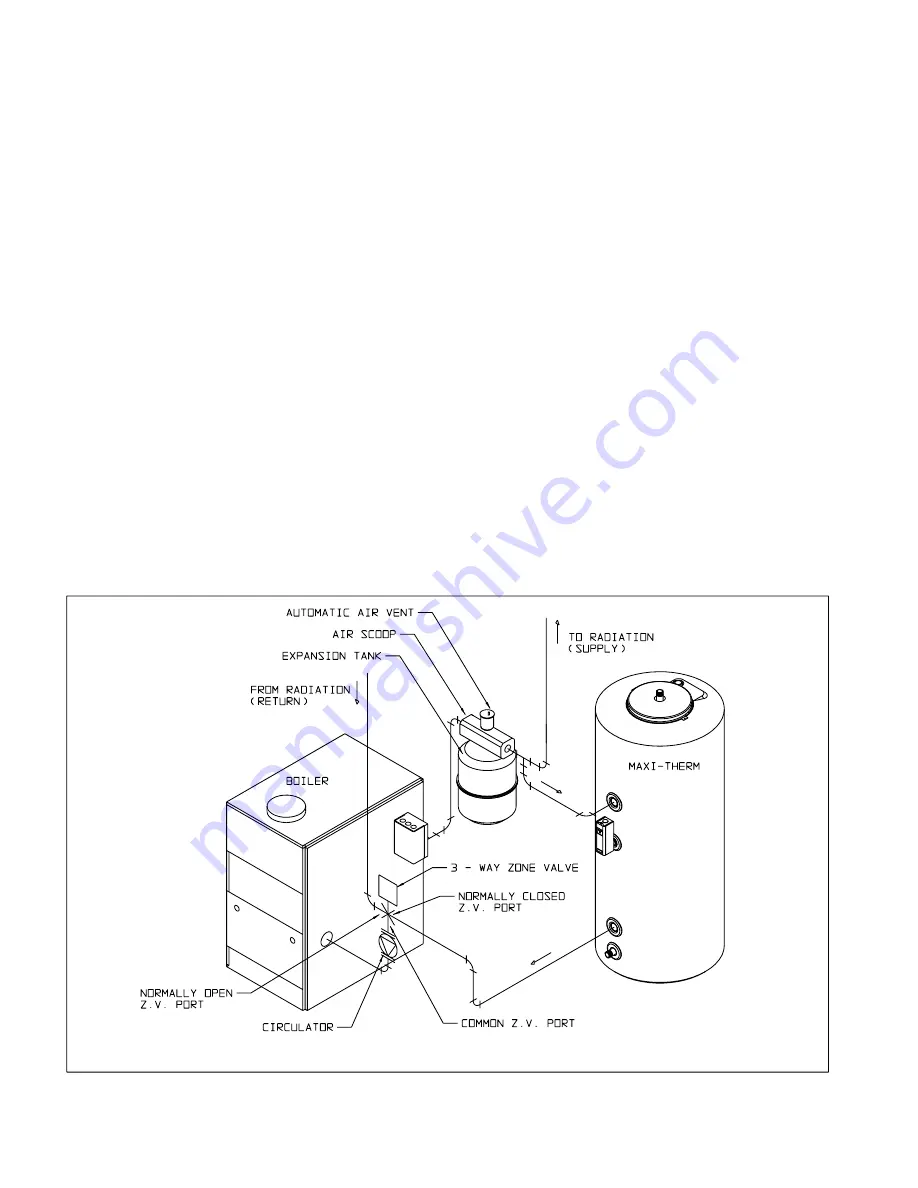

Figure 8: Boiler-Side Piping a 3-Way Zone Valve

22

Содержание MAXI-THERM MT040G

Страница 4: ...3 Figure 1b MT079G and MT100G General Configuration Figure 1a MT040G and MT050G General Configuration...

Страница 22: ...Figure 6 Boiler Side Piping Using Circulator Zones Figure 7 Boiler Side Piping Using Zone Valves 2 Way 21...

Страница 28: ...Figure 12 Basic Domestic Side Piping Figure 13 Domestic Side Piping Using a Mixing Valve 27...

Страница 30: ...Figure 15 Domestic Side Piping for Multiple Maxi Therms 29...

Страница 32: ...Figure 16 Non Priority Circulator Zoning Using Honeywell R845a s Figure17 PriorityCirculatorZoning 31...