13

English

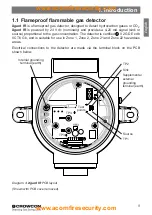

3.1 Commissioning procedure

1. Open the junction box of the detector by unscrewing the lid in an anti-clockwise

direction (having loosened the retaining grub-screw first).

2. Check that all electrical connections have been made and are correct, as shown in

Diagram 5.

3. Measure the voltage across the ‘+’ and ‘-’ terminals and check a minimum supply of

10 V d.c. is present.

4. Leave the detector to stabilise for at least 45 minutes.

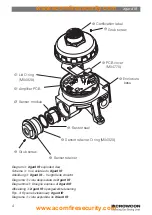

5. Remove the PCB cover and check the amplifier balance by connecting a Digital Volt

Meter (DVM) set to the dc mV range to test points TP3 and TP4 (see Diagram 4).

Adjust potentiometer VR3 so that the DVM reads ‘0.00 mV’. The PCB cover can now

be re-fitted.

6. To zero the detector, connect the DVM to the test points marked ‘TP1’ and ‘TP2’ on

the amplifier PCB, as shown in Diagram 4.

Note: At the test points, Zero will read 40 mV = 4 mA.

Full scale deflection will read 200 mV = 20 mA. There is a current clamp of 25 mA

on the 4-20 mA output.

Zeroing the detector

7.

Hydrocarbon detectors:

ensure the detector is in clean air. Adjust the ‘ZERO’

potentiometer (accessible via a hole in the PCB cover) until the DVM reads 40 mV.

Check that the control panel display reads 0%LEL.

Carbon Dioxide detectors:

as air contains 300/400ppm of CO

2

normally, the sen-

sor must be zeroed using 100% nitrogen test gas.

Apply 100% N

2

gas

at a flow-rate

of 0.5 litres per minute via a flow adaptor (part number C03005). Adjust the ‘ZERO’

potentiometer (accessible via a hole in the PCB cover) until the DVM reads 40 mV.

Check that the control panel display reads 0%. Remove the zero gas.

Calibrating the detector

8. Apply calibration gas (concentration should ideally be at least 50% of full scale

concentration) to the detector at a flow rate of 0.5–1 litre/minute via a flow adaptor

(Part No. C03005)

. Contact Crowcon for the supply of calibration gas.

WARNING

Prior to carrying out any work ensure local regulations and site procedures are

followed. Never attempt to open the detector or junction box when flammable

gas is present. Ensure that the associated control panel is inhibited so as to

prevent false alarms.