10

Crathco

®

Model 3311 Beverage Freezer

Cleaning and Maintenance (continued)

Disassembly and Cleaning

NOTICE:

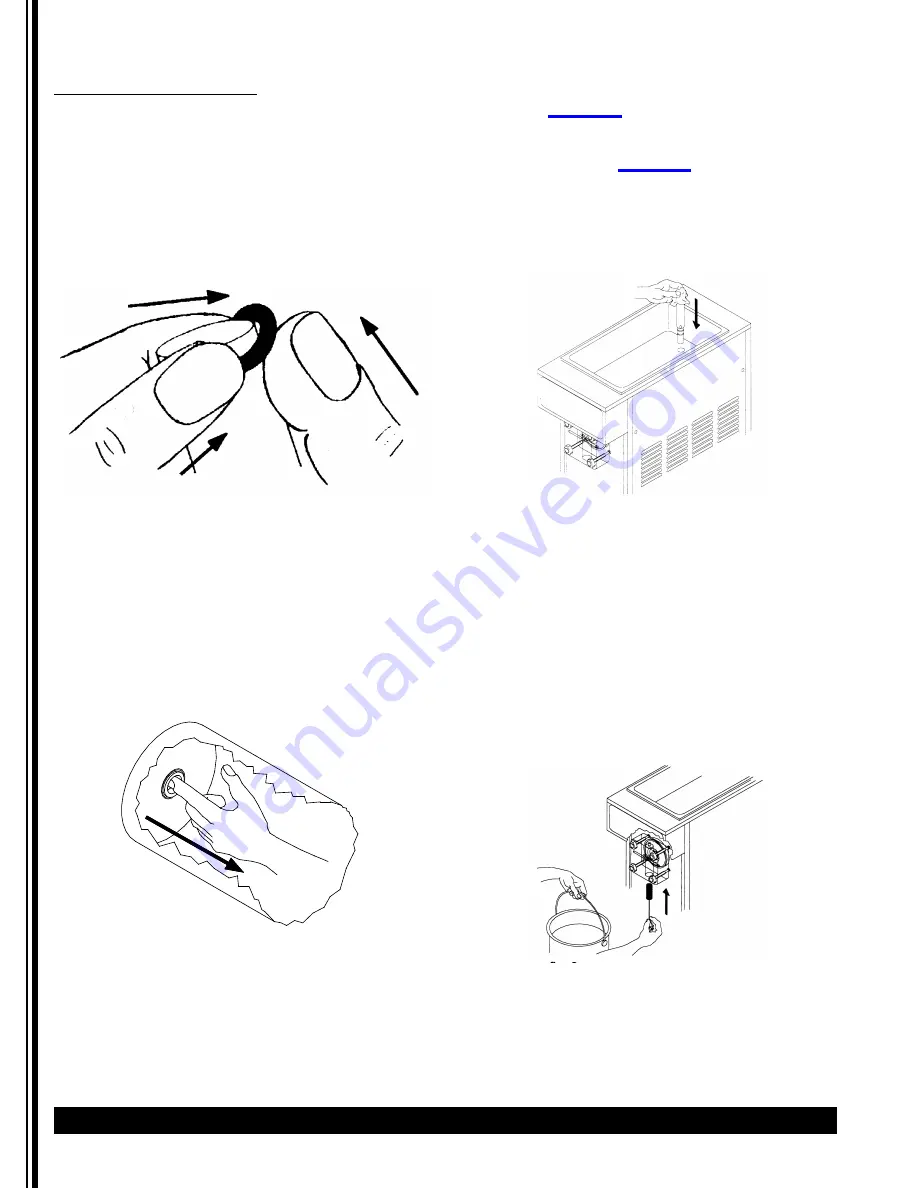

The best way to remove an O-ring is to first

wipe off all of the lubricant using a clean paper towel.

Pinch the O-ring upward with a dry paper towel

between your index finger and thumb. When a loop is

formed in the O-ring, roll it out of the groove with your

other thumb. Always remove the O-ring farthest from

the end of the plunger first. Be careful not to pull or

tug excessively on O-rings. O-rings can be distorted and

will deteriorate sealing performance.Carefully inspect

the O-rings and replace if necessary. (See Figure Q)

3. Remove the dasher assembly from inside the

freezing cylinder taking care to avoid damaging

the rear seal assembly at the back of the

freezing cylinder. Disassemble the dasher

assembly by removing the stator rod and front

and rear stator rod bearings.

4. Remove stationary half of the shaft seal

assembly from the back end of the freezer

cylinder. This is accomplished by reaching into

the cylinder and pulling seal out with your

index finger. (See Figure R)

5. Slide the rotary half of the seal off the dasher

shaft. Inspect both seal components carefully

for nicks or cracks. Replace seal if defective.

NOTICE:

To prevent leakage the surfaces of the rotary

seal and the stationary seal must be smooth with no

chips or cracks.

NOTICE:

All units are shipped with a standard ceramic

seal (Part #

) unless otherwise specified.

Certain products contain coconut oil which requires a

different sealing material. For these products use the

coconut oil seal (Part #

). The stationary half

of the standard seal has a white polished surface. The

stationary half of the coconut oil seal has a glossy black

surface.

6. Remove carb tube from bottom of hopper and

remove O-rings. (See Figure S).

7. Remove drip tray and empty contents.

8. Take all components to the cleaning area.

9. Prepare 1 gallon solution of hot tap water and

common dishwashing detergent.

10. Thoroughly wash all components in a warm,

mild detergent solution including the inside of

the freezing cylinder and the mix storage

hopper.

DO NOT WASH COMPONENTS IN A

DISHWASHER.

11. Use a medium sized brush to clean the bottom

of the valve body and the inside of the plunger

bore with detergent solution taking care to

remove only remaining lubricant. (Figure T)

12. The exterior of the freezer should be cleaned as

needed with a cloth towel.

NOTICE:

Coarse rags, abrasive cleaners

and excessive force can damage and/or

scratch the surfaces of the freezer.

Figure Q

Ring Removal

Figure R

Removal of stationary half of seal

Figure S

Carb Tube

Figure T

Clean Valve Body

Содержание Standard 3311

Страница 34: ...34 Crathco Model 3311 Beverage Freezer Spinner Hook Up Model 3311 AC WC Units 115V Model Model 3311 220V Model...

Страница 38: ...38 Crathco Model 3311 Beverage Freezer Refrigeration Schematic Model 3311 115 220V Air Cooled Models...

Страница 39: ...Model 3311 Beverage Freezer Crathco 39 Refrigeration Schematic continued Model 3311 Water Cooled Models...