7

4. During power black-outs, discontinue water

consumption to prevent sewage from backing up.

5. Prevent

infi ltration or direct fl ow of rain or run-off water

into the system to minimize pump cycling.

This will prevent overloading the treatment facility, and

will facilitate swift transportation of sewage.

6. Always keep the shut-off valve completely open when

system is in operation, (unless advised otherwise by the

proper

authorities).

7. Keep the control panel locked or confi ned to prevent

unauthorized access to it.

8. If the pump is idle for long periods of time, it is

advisable to start the pump occasionally by adding

water to the system.

9. Before removing the pump from the system, be sure

to close the shut-off valve. (This prevents backfl ow

from the pressure sewer.)

10. Make sure level controls are provided at time of

installation.

11. Recommended starts per hour, 6 to 8, no more than 10.

D-3) Start-Up Report:

Included at the end of this manual are two start-up report

sheets, these sheets are to be completed as applicable.

Return one copy to Barnes Pumps and store the second

in the control panel or with the pump manual if no control

panel is used. It is important to record this data at initial

start-up since it will be useful to refer to should servicing

the pump be required in the future.

D-3.1) Identifi cation Plate:

Record the numbers from the pump’s identifi cation plate

on both START-UP REPORTS provided at the end of the

manual for future reference.

SECTION E: SERVICE AND REPAIR

NOTE: All item numbers in ( ) refer to Figures 8 & 9.

WARNING ! - Electrical power to the pump

motors must be disconnected and locked out

to prevent any dangerous electrical hazards

or personnel danger before any service work

is done to the pump.

CAUTION ! - Operating pump builds up heat

and pressure; allow time for pump to cool

to room temperature before handling or

servicing.

E-1) Lubrication:

Anytime the pump is removed from operation, the oil in

the seal chamber (27) should be checked visually for oil

level and contamination.

E-1.1) Checking Oil:

With a fl ashlight, visually inspect the oil in the seal

chamber (27) to make sure it is clean and clear, light

amber in color and free from suspended particles.

Milky white oil indicates the presence of water. Oil must

completely fi ll the seal chamber.

E-1.2) Testing Oil:

1. Place pump on it’s side, remove pipe plug (27) on and

drain oil into a clean, dry container.

2. Check oil for contamination using an oil tester with a

range to 30 Kilovolts breakdown.

3. If oil is found to be clean and uncontaminated

(measure above 15 KV. breakdown), refi ll seal

chamber housing as per section E-1.3.

4. If oil is found to be dirty or contaminated (or measures

below 15 KV. breakdown), the the pump must be

carefully inspected for leaks at the shaft seals (5) &

(12), pipe plug (27), O-rings (11) & (20) before refi lling

with oil. To locate the leak, perform a pressure test as

per section E-1.4. After leak is repaired, refi ll with new

oil as per section E-1.3.

E-1.3) Replacing Oil:

Seal Chamber- Set unit on its side with fi ll plug (27)

downward, (located on intermediate coupling 6), remove

plug (27) and drain all oil from seal chamber. Set unit on

its side, with plug (27) upward, and refi ll completely with

(see parts list for amount) new oil as per Table 1. Apply

pipe thread compound to threads of pipe plug (27) and

assemble to intermediate coupling (6).

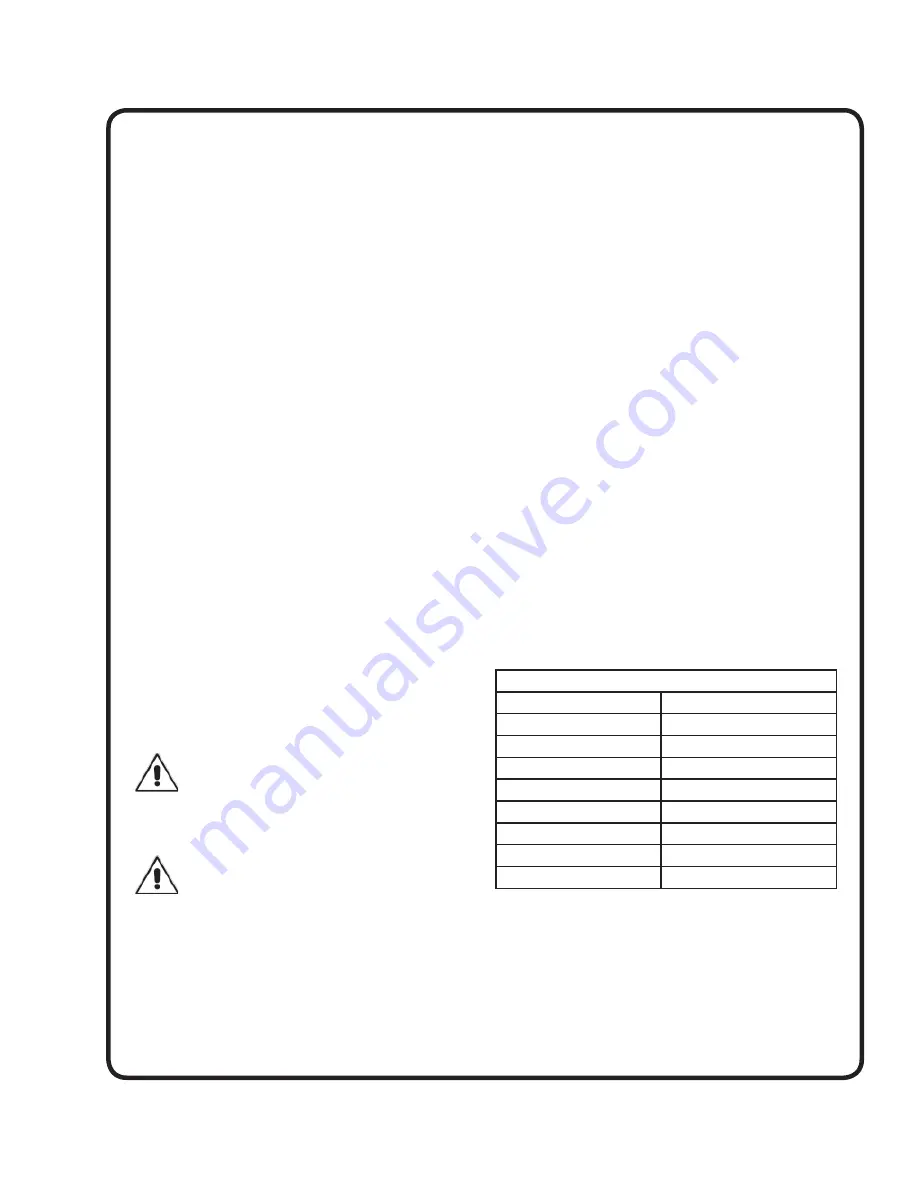

TABLE 1 - COOLING OIL - Dielectric

SUPPLIER

GRADE

BP

Enerpar SE100

Conoco

Pale Paraffi n 22

Mobile

D.T.E. Oil Light

G & G Oil

Circulating 22

Imperial Oil

Voltesso-35

Shell Canada

Transformer-10

Texaco

Diala-Oil-AX

Woco

Premium 100

E-1.4) Pressure Test:

Seal Chamber -

Remove pipe plug (27) from

Intermediate Coupling (6) and check that the seal

chamber is full of oil. Apply pipe sealant to pressure

gauge assembly and tighten into hole in Intermediate

Coupling (6).

Содержание DGV2042

Страница 12: ...12 FIGURE 8 ...

Страница 13: ...13 FIGURE 9 ...