6

4. a. If the pump is furnished with threaded discharge

fi ttings, unscrew the pipe coupling or fl ange

(295) from the top end of the discharge pipe

then remove the top pipe nut (294) and unscrew

the lower pipe nut to the end of the threads.

Unscrew the discharge pipe (161) from the

discharge elbow (105).

b. If the pump is furnished with combination elbow

(105), remove the cap screws and nuts (267)

and (268) at the pump discharge fl ange.

5. Liquid end disassembly

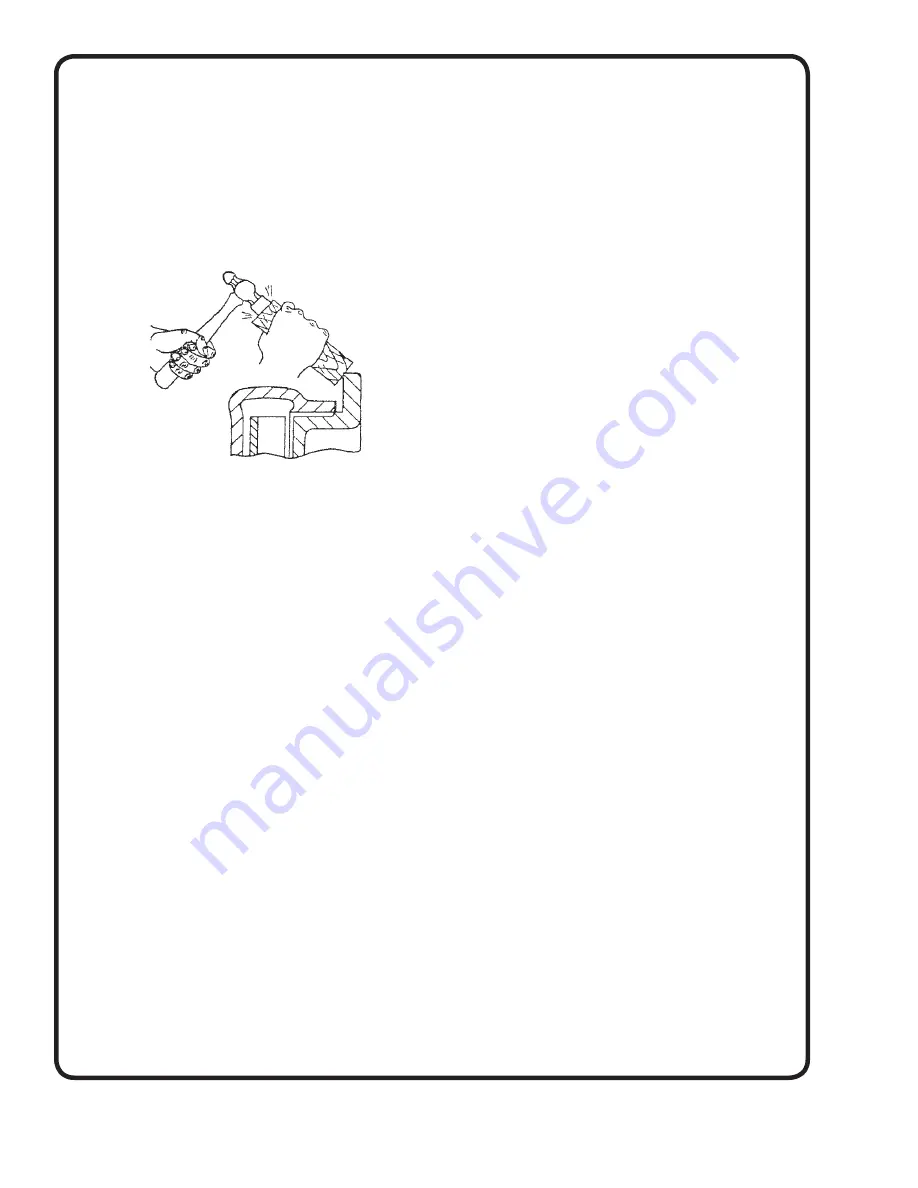

a. Remove cap screws (215), then place a block

of wood against the fi nished fl ange or back

of the suction cover (9) and tap the block lightly

with a hammer to loosen the suction cover.

Remove the suction cover and the gasket (73).

b. Bend and remove the cotter pin (269) and the

castellated impeller nut (24). Hold shaft with a

wrench at the coupling (42) and unscrew the

impeller nut (24) by turning counter clockwise,

also remove the impeller washer (270).

c.

To remove impeller (2) from the shaft (6) it will

be necessary to make 3 special jackscrews

depending upon the size of the liquid end as

follows:

1.) If the discharge outlet of the casing (1)

is threaded 1”, 1½” or 2½” and the

impeller diameter is 6” or less, the

required jackscrews are 3/8” x 16NC,

1¾”

long.

2.) For all other sizes of liquid ends the

required jackscrews are 1/2” x 13NC, 3”

long.

Thread the jackscrews into the 3 tapped holes

in the impeller shroud and tighten alternating

jackscrews, until the impeller is forced from

the shaft. Lift impeller key (32) from its seat.

d. The casing (1) and throttle housing (99) may be

removed from the column pipe (101) after

removing cap screws (212).

e. Inspect the throttle bushing (252) for excessive

wear and replace by unscrewing the cap screw

(218) and pressing the bushing from the

housing. Press new bushing into the throttle

housing (99), aligning the slot with the cap screw

(218) then tighten cap screw until fi rm. Slide

defl ector (40) from the shaft.

L - TO INSPECT BALL BEARINGS &

SEALS OR SHAFT

1. Remove Liquid end assembly.

2. Remove coupling (42) and key (46) from shaft (6).

3. Remove cap screws (221) and nuts (261) and lift

driver pedestal (81) from frame (19).

4. Remove cap screw (213). Unscrew the 3 lock nuts

(204) until against the head of the jackscrew (286)

then remove jackscrews. Slide bearing cover (37)

with seal (49) off the top end of the shaft (6). Inspect

the seal and replace if worn.

5. Bend tape on bearing lock washer (69) then unscrew

and remove the bearing lock nut (22) and bearing

lock washer (69).

6. Replace the jackscrews (286) in the bearing housing

fl ange and toghten the jackscrews to raise the

bearing housing (33) and ball bearing (18) from the

top of the frame (19). A pry bar may be required to

assist in removing the bearing housing. Carefully

press the ball bearing from the bearing housing.

7. Carefully withdraw the pump shaft and ball bearing

(16) upward through the frame (19). Remove the

bearing (16) from the shaft.

8. Inspect the bearing cover seal (47) and if worn

replace with new seal. Bearing cover (35) and seal

may be removed from the frame using a piece of

pipe or tubing inserted through the top of the frame

to force the bearing cover from the frame.

M - TO REASSEMBLE BALL

BEARINGS AND SEALS

1. Slide bearing (16) onto the shaft. Position the

bearing so that the inner bearing race is against the

shaft

shoulder.

CAUTION:

Apply force only to the

inner bearing race.

2. If the bearing cover (35) and the seal (47) were

removed from the frame, apply suffi cient grease to

fi ll the space below the ball bearing (16). Press

bearing cover with seal into the frame from the

impeller end until the bearing cover is fl ushed with

the frame. Be sure that seal (47) is installed with the

spring side of the seal toward the impeller.

Содержание DEMING 5460 Series

Страница 12: ...Notes ...