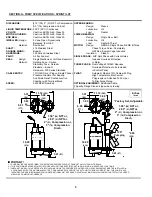

F-2.3 Bearing:

Place bearing (26) in bearing installation tool (Fig. 8) and place

in position on an arbor press. Place motor rotor over bearing,

align and press down until retaining ring is seated against

bearing.

F-2.4 Rotor:

Place drive end bell (29) with bearing side up on arbor press,

align rotor assembly with bearing and retaining ring installed,

over center of drive end bell, lower rotor thru bearing bore

taking care not to damage seal seat on opposite side. When

bottom of bearing comes into contact with bearing bore, square

up shaft and press rotor assembly into drive end bell until

bearing is seated.

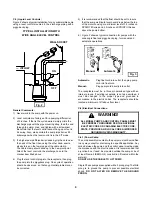

F-2.5 Shaft Seal:

Place two or three drops of oil on face of ceramic seat. Slide

the rotating member on the shaft so that the face washer will

make contact with the ceramic seat. Tamp the square rubber

ring into the stainless steel case if required. CAUTION: There

cannot be oil on the pump shaft where the rubber ring seats as

it will allow the rotating member of seal to slide off of shaft

shoulder before seal retaining tool can be installed (see Fig. 5)

Be sure seal is installed square and true.

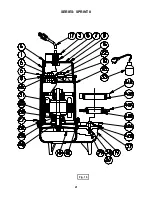

F-2.6 Motor:

After motor has been resistance checked as described in

Section D-4, assemble motor to end bell (29) with 4 motor bolts.

Place Tetraseal (28) in groove in end bell (29) and lower shell

(13) over motor while feeding leads out terminal block opening,

and bolt to end bell with screws (12). Place o-ring (16) over

motor leads and make connectiond as shown in Figs. 10 thru

14. Secure terminal block (15) with 4 round head screws (14).

Conduct motor air check per Section F-1.4 and fill with oil per

Section F-1.3.

F-2.7 Current/Voltage Relay:

The .5HP units use a current relay (22) and 1HP units use a

voltage relay. Mount relays with terminals up using screws (10).

F-2.8 Starting Capacitor:

The

1HP units use a start capacitor (20). Retain capacitor with

o-ring (21) and two mounting brackets (24). O-ring is retained

under each bracket and stetches over capacitor.

F-2.9 Cord and Cover:

Apply thread sealent to cord grip (5) and install in cover (2).

Insert cord set (17) thru cord grip (5) and tighten compression

nut to secure cord. Insert Tetraseal (9) into groove on shell (13).

Connect cord set (17) to terminal block and assemble pump

cover onto shell using screws (6). See Fig. 9 for pump cover to

shell location. Check for ground per Section D-4. Check

rotation per Section D-2 and Air check per Section F-1.4.

Fig. 9

POSITION OF PUMP COVER (1) WITH SHELL (13).

CURRENT/VOLTAGE

RELAY

MOTOR SHELL

PUMP COVER

Fig. 8

TOOL USED FOR INSTALLATION OF BEARING

ON ROTOR.

MATERIAL: 4.00" DIA. C.R.S. OR EQUIV.

16

Содержание Barnes SPRINT II Series

Страница 13: ...Fig 4 CONNECTION DIAGRAMS USED FOR DETERMINING WINDING RESISTANCE 13 ...

Страница 21: ...Fig 15 SERIES SPRINT II 21 ...

Страница 22: ...Fig 16 SERIES SPRINT II 22 ...

Страница 25: ...SERIES SPRINT III Fig 17 25 ...

Страница 26: ...SERIES SPRINT III Fig 18 26 ...

Страница 28: ...NOTES 28 ...