C-3) Liquid Level Controls:

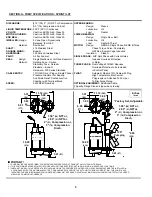

Figure 2 shows a typical installation for any submersible pump

using a level control mounted to the discharge piping with a

piggy-back plug.

General Comments:

1) Never work in the sump with the power on.

2) Level controls are factory set for a pumping differential

of 9 inches. If that is the cycle desired, simply circle the

discharge pipe with the pipe mounting strap, feed the end

through the worm drive, and tighten with a screwdriver.

Be certain that the level control cannot hang up or foul in

it’s swing. Also, make certain the pump impeller is still

submerged when the level control is in the ’off’ mode.

3) If a higher pump differential is needed, grip the cord near

the neck of the float, then using the other hand, exert a

steady force on the lower edge of the cable clamp.

The cable clamp should slide up to the new pivot point.

Attach the level control to the discharge hose in the

manner described above.

4) Plug the level control plug into the receptacle, then plug

the pump into the piggyback plug. One cycle of operation

should be observed , so that any potential problems can

be corrected.

5) It is recommended that the float should be set to insure

that the sump well liquid level never drops below the top

of the motor housing or a minimum level of 3.5 inches on

SPRINT II Series and 5.5 inches on SPRINT III Series

above the pump bottom.

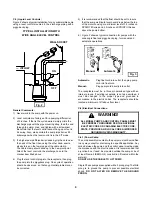

6.) Figure 3 shows a typical connection for pumps with the

wide angle float and piggy-back plug, for manual and

automatic operations.

Automatic-

Plug float cord into outlet, then plug pump

cord into float cord.

Manual-

Plug pump cord directly into outlet.

The receptacle must be a three pin polarized type with an

internal ground. If existing receptacle is not as described, it

must be changed to the proper type and grounded in

accordance to the electric codes. The receptacle should be

located a minimum of 4ft above floor level.

C-4) Electrical Connections:

WARNING!

ALL MODEL PUMPS AND CONTROL PANELS MUST

BE PROPERLY GROUNDED PER THE NATIONAL

ELECTRIC CODE OR CANADIAN ELECTRIC CODE,

STATE, PROVINCE AND LOCAL CODES. IMPROPER

GROUNDING VOIDS WARRANTY.

C-4.1) Power Cable:

The cord assembly mounted to the pump must not be modified

in any way except for shortening to a specific application. Any

splice between the pump and the control panel must be made

in accordance with the electric codes. It is recommended that

a junction box, if used, be mounted outside the sump or be of

at least Nema 4 (EEMAC-4) construction if located within the

wet well.

DO NOT USE THE CABLE TO LIFT PUMP.

Single Phase pumps are supplied with a 3 prong plug. The third

prong is to ground the pump to prevent possible electrical

shock.

DO NOT ALTER OR REMOVE THE GROUND

PRONG.

WALL SOCKET

DISCHARGE

⇒

⇒

INFLOW

TYPICAL INSTALLATION WITH

WIDE ANGLE LEVEL CONTROL

ON

OFF

Fig. 2

Fig. 3

Automatic

Manual

9

Содержание Barnes SPRINT II Series

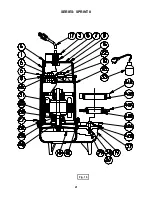

Страница 13: ...Fig 4 CONNECTION DIAGRAMS USED FOR DETERMINING WINDING RESISTANCE 13 ...

Страница 21: ...Fig 15 SERIES SPRINT II 21 ...

Страница 22: ...Fig 16 SERIES SPRINT II 22 ...

Страница 25: ...SERIES SPRINT III Fig 17 25 ...

Страница 26: ...SERIES SPRINT III Fig 18 26 ...

Страница 28: ...NOTES 28 ...