15

SERVICE AND MAINTENANCE

WARNING

Always stop engine, disconnect spark plug wire, and ground against engine

before performing any type of maintenance on your machine.

Oil Service

•

Check oil level regularly.

•

Be sure correct oil level is maintained. Check every five hours or daily before

starting engine. See oil checking procedure in the Operation section.

Oil Change

IMPORTANT:

Be sure to check engine on a level surface with the engine stopped.

Drain the oil while the engine is still warm to assure rapid and complete draining.

1.

Remove all fuel from tank by running engine until it stops from lack of fuel.

2.

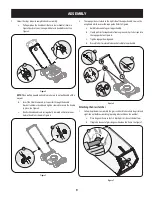

Remove drain plug and allow oil to drain into a suitable container. See Figure

16.

Oil Fill Cap

Drain

Plug

Figure 16

WARNING

Before tipping engine or equipment to drain oil, drain fuel from tank by

running engine until fuel tank is empty.

3.

Reinstall the drain plug and tighten it securely.

4.

Refill with the recommended oil and check the oil level. Refer to the Set-Up

section.

5.

Reinstall the oil fill cap securely.

IMPORTANT:

Used motor oil may cause skin cancer if repeatedly left in contact with

the skin for prolonged periods. Although this is unlikely unless you handle used oil

on a daily basis, it is still advisable to thoroughly wash your hands with soap and

water as soon as possible after handling used oil.

NOTE:

Please dispose of used motor oil in a manner that is compatible with the

environment. We suggest you take it in a sealed container to your local service

station for reclamation. Do not throw it in the trash or pour it on the ground.

Air Filter Service

Paper filters cannot be cleaned and must be replaced once a year or every 100

operating hours; more often if used in extremely dusty conditions.

WARNING

Never use gasoline or low flash point solvents for cleaning the air filter

element. A fire or explosion could result.

IMPORTANT:

Never run the engine without the air filter. Rapid engine wear will

result.

1.

Press down on the tabs securing the air filter cover. Pull back and remove the

cover. See Figure 17.

Paper Element

Tab

Figure 17

2.

Remove the paper element. To loosen debris, gently tap the filter on a hard

surface. If the filter is excessively dirty or damaged, replace with a new filter.

3.

Insert the cover’s bottom tabs into slots in bottom of base.

4.

Tilt the cover up into place and secure with tabs.

Carbon Canister Filter Service

The foam carbon canister filter must be cleaned or replaced once a year or every 100

operating hours.

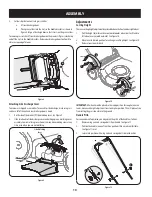

1.

Remove outer engine shroud and recoil starter housing as shown in Figure 18.

2.

Lift up inner engine shroud and carefully pull out carbon canister filter

assembly from under shroud as shown in Figure 18.

3.

Remove cap from end of canister and pull out round foam filter from inside

the assembly. See Figure 19. Clean element or replace when damaged.

4.

To clean foam element, wash in mild liquid detergent and water. Squeeze or

press the foam element to rinse out dirt and water. Do not twist, this could

damage or tear the foam element. Allow to dry thoroughly before using. Oil

the foam element with a light engine oil.

5.

Carefully place foam filter back into canister assembly and reattach the

rubber cap removed earlier.