20 • MultiFlex I/O Board Operator’s Guide

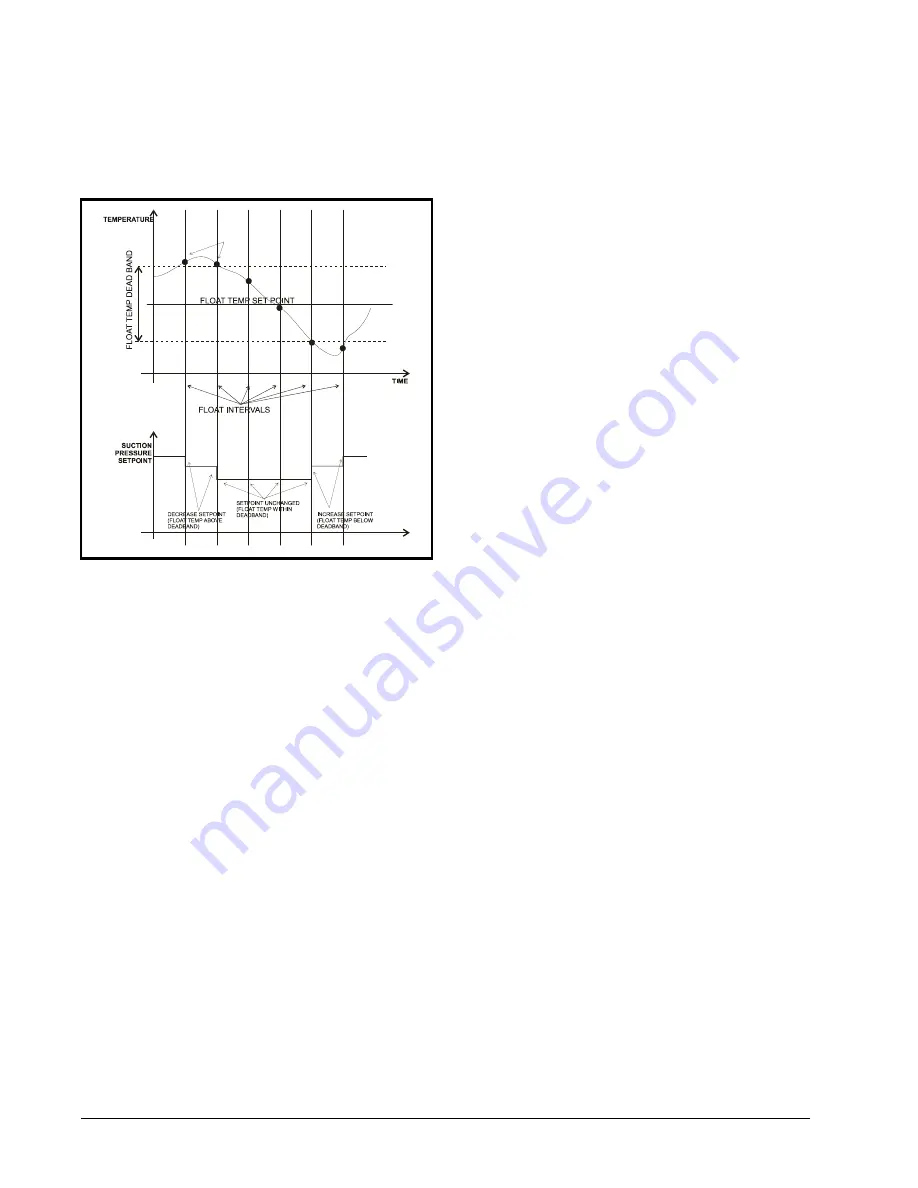

temperature in line with the float setpoint. A

graph showing an example of suction pressure

setpoint adjustment versus float temperature is

provided in

.

The amount of the interval for each adjust-

ment, as well as the frequency of adjustment, is

programmable by the user. Also, the user must

specify a minimum and maximum range for the

suction setpoint to prevent suction float from

floating the setpoint too high or too low.

6.1.5.1.

Suction Float Input Sources

Up to 20 case temperatures may be used to

provide the combined case temperature used

during suction float. The E2 may use case tem-

peratures from:

•

Standard Circuit applications in the E2,

•

Emerson Climate Technologies EC2 case

controllers,

•

Danfoss EKC514 SNMP case controllers,

•

WCC case controller (Microm/Tektronix/

Barker/Elm/CDK),

•

Danfoss DFMC Micro-Cool case controllers.

Each case temperature input value used in

the combination is determined by taking the

average value of the input over a time window

(called the averaging window), which averages

all sampled temperatures between the current

time and

x

minutes before the current time

(where x is the user-defined averaging window

time period). Once the averages of each input are

determined, these values are then combined into

a single temperature by calculating either the

average value, the median value, or the maxi-

mum value. The result, called the

float temper-

ature

, is compared to the float setpoint to

determine which direction to float the suction

pressure setpoint.

6.1.5.2.

Defrost Inhibit

All case temperatures used as inputs for Suc-

tion Float are only used in the combined case

temp calculation if they are in refrigeration

mode. If a case is not in refrigeration mode, its

temperature input value will be ignored.

This includes cases in defrost, pump down,

drip or "drain" mode, clean or "wash" mode, and

cases whose case control devices are offline or

otherwise shut down.

If a case that is being inhibited returns to

refrigeration mode, the E2 will wait for a user-

defined delay period to elapse before including

its temperature value in the combined case temp

calculation. The inhibit delay is designed to

allow the case enough time to recover its case

temperature setpoint.

6.1.5.3.

Bad Case Temp Inhibit

In addition to excluding case temperatures

from circuits or case controllers that are not in

refrigeration, the PAK application in the E2 will

exclude up to a user-defined number of case

temperatures from cases determined to be "poor

performers." A poor-performing case is defined

as one whose temperature deviates outside of the

float temperature deadband.

Figure 6-1

- Suction Pressure Setpoint Vs. Float Temperature

Содержание MultiFlex PAK

Страница 1: ...026 1712 Rev 3 03 JAN 2008 MultiFlex PAK Compressor Condenser Control Board User s Guide...

Страница 2: ......

Страница 4: ......

Страница 8: ......