Technical Support Manual – 03/2017 Rel. 0

Page 46

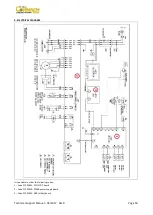

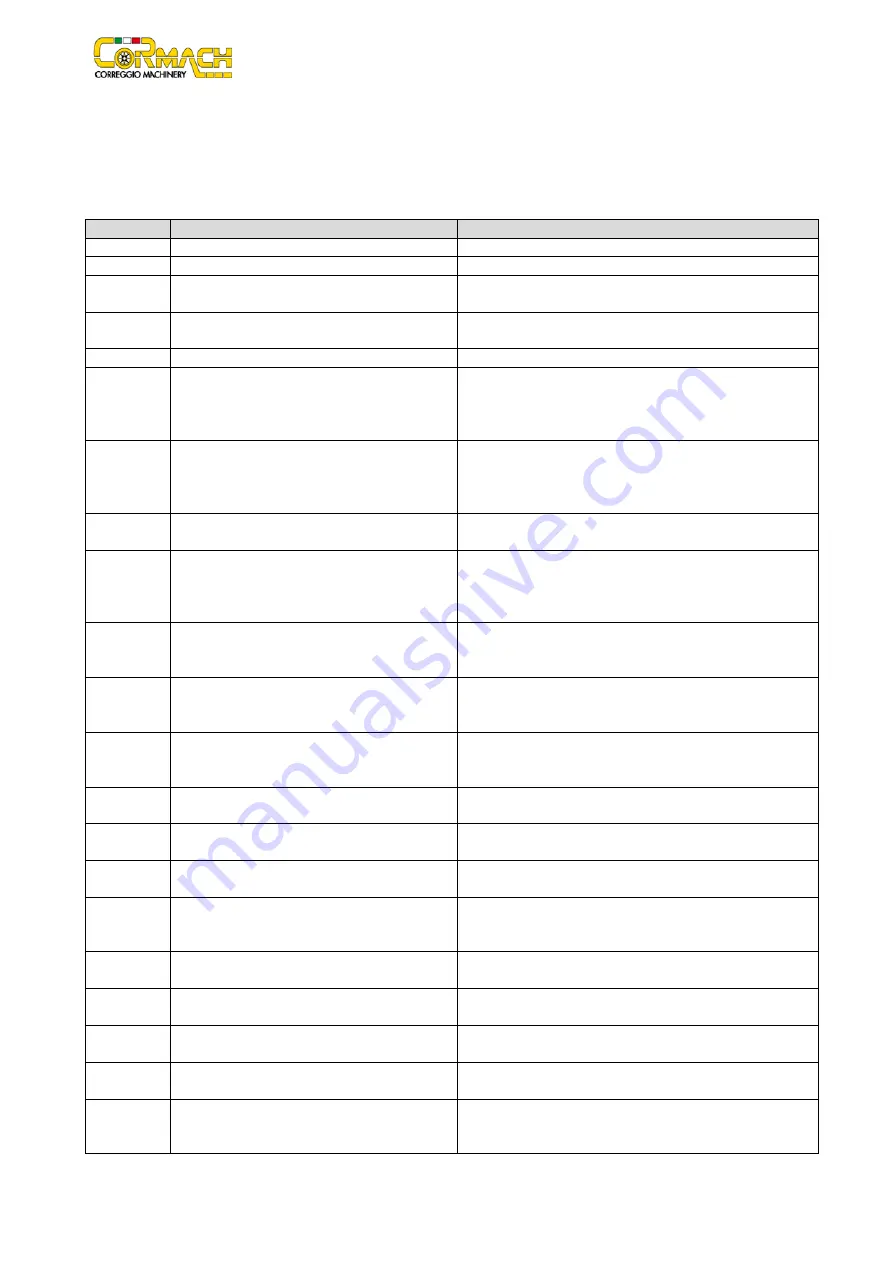

5. ERROR AND WARNING CODES

The machine indicates error conditions by alternating the display of an error code with a brief description (in English) of the error

cause. The machine displays the code for different times depending on the error code itself, as indicated in the "Display" column in

table T5.1.

Table T5.1: Error codes

Code

Description

Notes

000 to 009

ERROR: Machine parameters internal error.

Change the CPU-LCD board.

010

ERROR: Reverse rotation of the wheel.

Change the power supply board.

011

WARNING: Wheel speed too low.

1.

Check the mains voltage.

2.

Check belt and pulley tension.

012

ERROR: The wheel cannot be stopped at the end

of the launch.

1.

Check the ENCODER.

2.

Check the power supply board.

013

ERROR: Wheel speed too high.

Change the power supply board.

014

ERROR: The wheel does not spin.

1.

Check the MICRO guard.

2.

Power supply board.

3.

CPU board.

4.

ENCODER disc.

019

WARNING: No communication processor

Turn the machine off and then on again. If the error persists,

contact technical support.

The machine can still be used but all functions related to the

USB port are disabled.

020

ERROR: No communication with the eeprom

memory.

Turn the machine off and then on again. If the error continues,

change the CPU-LCD board.

021

WARNING: No machine calibration data or

incorrect calibration data.

Carry out calibration for the CAR/SUV Wheel Type and/or for

the MOTO Wheel Type. If the error persists, contact technical

support.

Also see ERR 030 and ERR031.

022

ERROR: Pick-up A channel excessively high.

Excessive imbalance or anomaly. Turn the machine off and then

on again. If the error continues, check whether pick-up is

broken. Change the pick-up.

023

ERROR: Pick-up B channel excessively high.

Excessive imbalance or anomaly. Turn the machine off and then

on again. If the error continues, check whether pick-up is

broken. Change the pick-up.

024

ERROR: Internal timer channel excessively high.

Excessive imbalance or anomaly. Turn the machine off and then

on again. If the error continues, check whether pick-up is

broken. Change the pick-up.

025

WARNING: Presence of weight during the Cal0

calibration phase.

Remove the weight and repeat the launch of the Cal0 phase. If

the error persists, contact technical support.

026

WARNING: Launch without weight or no pick-up

A signal in the Cal2 calibration phase.

Apply the intended weight and repeat the launch. If the error

persists, contact technical support.

027

WARNING: Launch without weight or no pick-up

B signal in the Cal2 calibration phase.

Apply the intended weight and repeat the launch. If the error

persists, contact technical support.

028

WARNING: Launch with weight on the internal

side during the Cal3 calibration phase. In this

phase, the weight must be on the external side.

Remove the weight from the internal side and repeat the

launch. If the error persists, contact technical support.

030

WARNING: No calibration data for the CAR/SUV

(passenger car and off-road vehicle) Wheel Type.

Carry out the calibration of the machine for the CAR/SUV Wheel

Type.

031

WARNING: Lack of calibration data for the MOTO

(motorbike) Wheel Type.

Carry out machine calibration for the MOTO Wheel Type.

032

WARNING: Diameter sensor not calibrated.

ONLY TECHNICAL STAFF.

Calibrate the Diameter sensor.

034

WARNING: The MOTO Wheel Type: it is not

possible to use a Program Type other than ALU1.

Other Program Types cannot be selected.

035

WARNING: The electromagnetic stopping brake is

disabled: it is not possible to perform the SWI

procedure at a low speed.

Enable the electromagnetic stopping brake.

Содержание TOUCH MEC 1000 SONAR

Страница 1: ...WHEEL BALANCERS TOUCH MEC 1000 SONAR TECHNICAL SUPPORT MANUAL UK...

Страница 2: ......

Страница 5: ...Technical Support Manual 03 2017 Rel 0 Page 3 4 At the end of the test the machine is in NORMAL mode 5...

Страница 53: ......