3

Cooper Tools GmbH, Carl-Benz-Str. 2, 74354 Besigheim, P.O. Box 1351

Germany, Tel: (07143) 580-0, Fax: (07143) 580108

1

Description

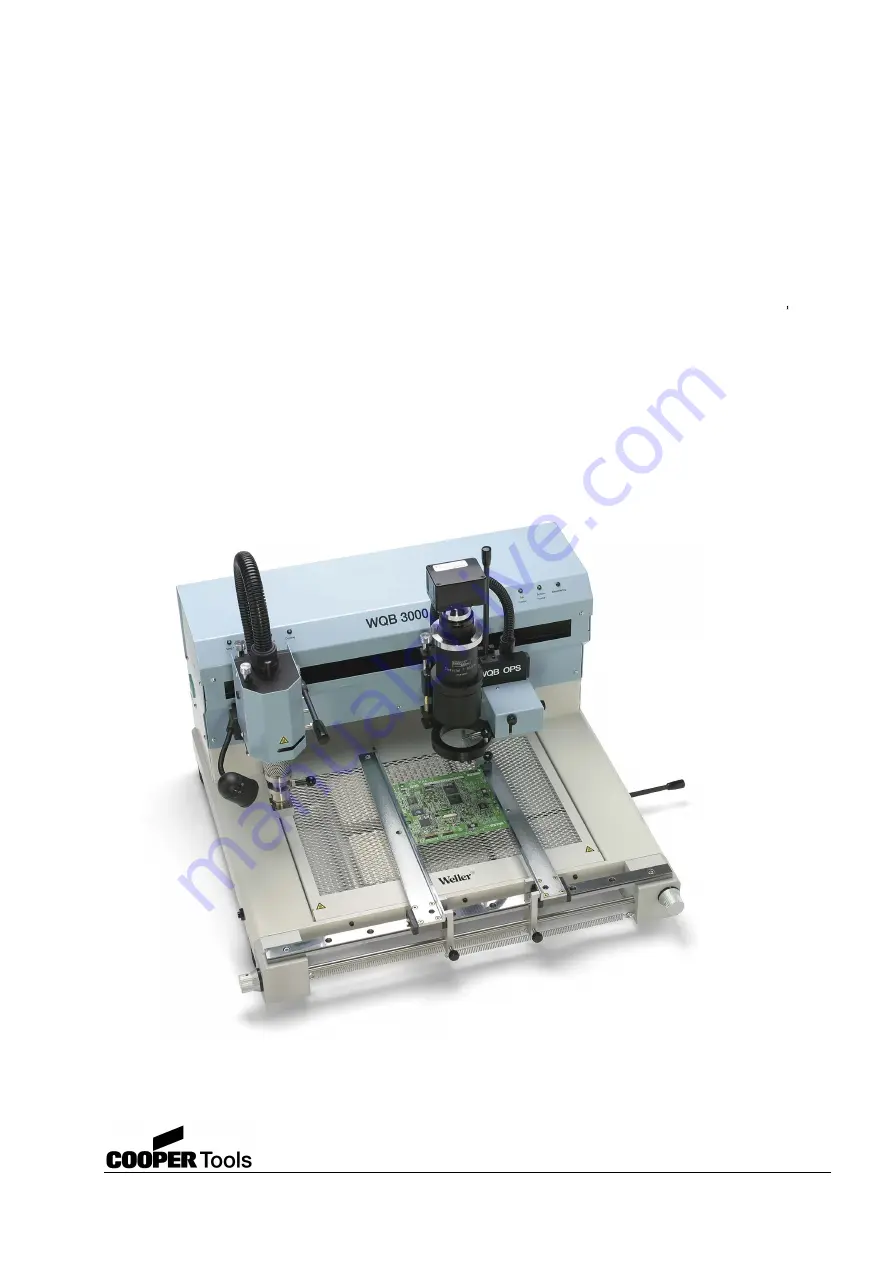

With the new WQB OPS, Weller is again demonstrating its extensive capacity for innovation in the repair

sector and presents a new type of camera positioning system for the WQB 3000 rework system. Using this

system all common components up to a minimum length of 3 x 3 mm can be reliably and precisely placed on

circuit boards.

The heart of the positioning system is the modern FireWire

TM

CCD camera with full digital data transfer. The

high image resolution, the excellent image quality at high rates of movement, and very low image noise

create the prerequisites for universal, precise, and ergonomic component placement. The data transfer from

the camera to the PC is made in real time via the IEEE 1394a interface using the OHCI protocol. Distortion

free pictures of the component to be placed can be achieved using the telecentrical objective lens, that s the

prior condition for a precise component placement.

The component placing software includes a component library from which the component to be positioned is

selected. New components can be very straightforwardly edited and inserted by the user.

With the aid of positioning frames displayed in the live image from the camera, both the circuit board and the

component are aligned independently using the x, y and theta precision drives. On key press the positioned

component will be set down automatically onto the circuit board and the vacuum be switched off. This

prevents undesired movement of the component during the lift down of the component onto the circuit board.