3

MPA IO&M

B51223-005

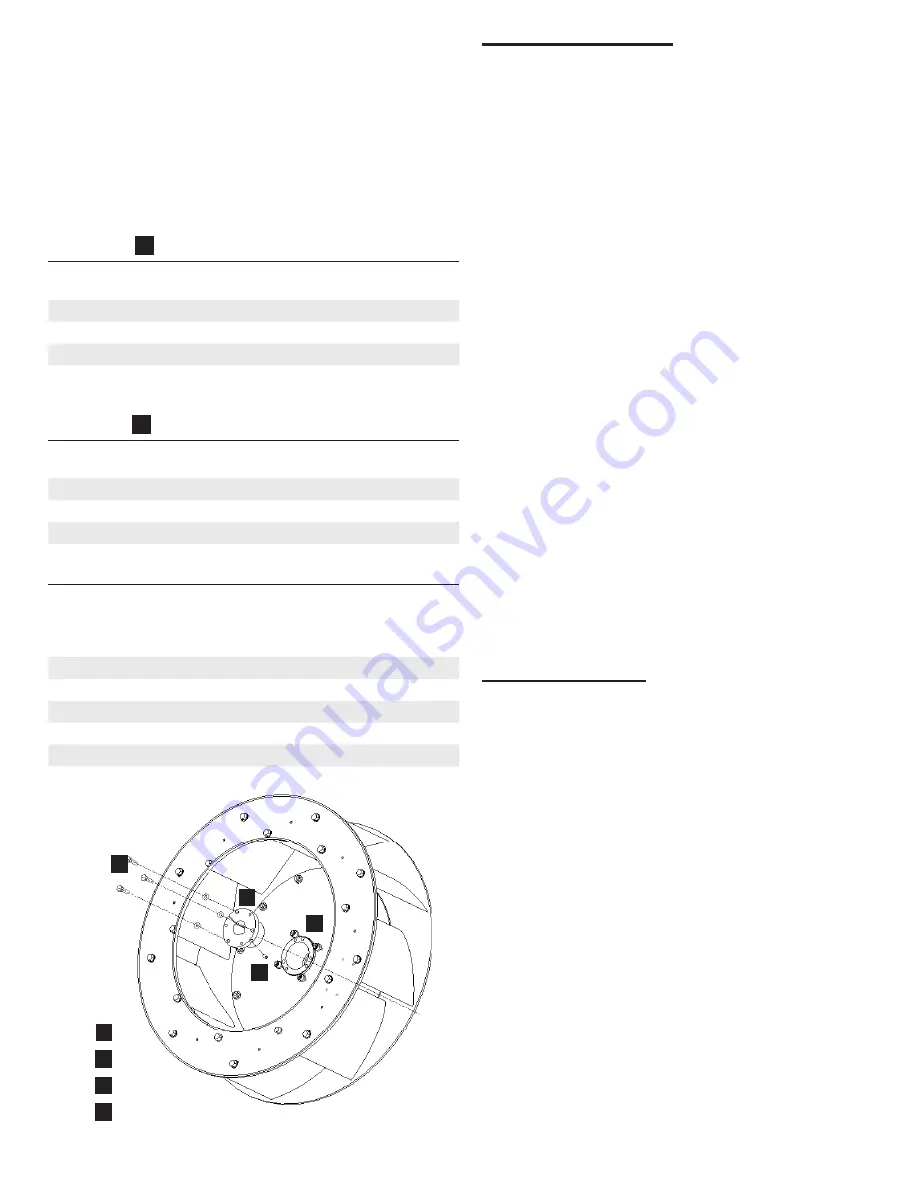

Hub

Bushing

Bushing Screws

Bushing Set Screw

D

C

B

A

D

C

B

A

Verify fastener tightness, these may have loosened

during shipment or installation:

• Bushing set screw torque

• Bolts on inlet funnel.

• Motor bolt torque

• Nuts holding housing frame to base and base to ground

(customer specifications)

• Bushing fastener torque

• Ensure piezo ring tubing will not contact the impeller

Perform list again until unit is operating properly.

Motor Maintenance

The three basic rules of motor maintenance are to keep the

motor clean, dry, and properly lubricated. Keeping motors

and windings clean is important because dirt and dust

can cause heat to be trapped causing overheating and/or

premature failure. Blow dust and dirt out of windings and off

the motor periodically. Use low pressure (50 psi) airstream

to prevent winding damage. Keep the areas surrounding the

motor clear so the air can circulate through the motor cooling

fan.

Motors should be kept dry to avoid electrical short circuits.

Motors kept in storage for long periods of time can have

moisture condense on the windings. Be certain the motor is

dry before using.

Some smaller motors are permanently lubricated. Motor

bearing lubrication, if required, must follow a rigorous

schedule. Motors less than 10 hp running eight hours a

day in a clean environment should be lubricated once

every five years; motors 15 to 50 hp, every 3 years; and

motors 50 to 150 hp, yearly. See motor manufacturer

specifications for recommended greases. For motors in a

dusty or dirty environment or running 24 hours a day, divide

the service interval by 2. If the environment is very dirty or

high temperatures exist, divide the service interval by 4.

Lubrication requirements are normally attached to the motor.

Do not over-lubricate.

The major cause of motor bearing failure is contamination

of grease, insufficient grease, over lubrication, and

incompatibility of grease. If a fan is to be stored for any

length of time and the bearings are re-greasable, the motor

bearings should immediately be filled with grease while

rotating the fan and then the bearings should be re-greased

and rotated monthly. This will prevent moisture, which

condenses within the bearing, from corroding the raceways.

Troubleshooting

Use safety practices when investigating fan or system

performance problems. General safe practices and

performance troubleshooting guidelines can be found in

AMCA Publication 410: Recommended Safety Practices for

Users and Installers of Industrial and Commercial Fans, and

AMCA Publication 202-98 (R2011): Troubleshooting. Fan

application and field measurement procedures can be found

in AMCA Publication 201-02 (R2011): Fans and Systems

and AMCA Publication 203-90 (R2011): Field Performance

Measurement of Fan Systems.

The following chart on page 4 indicate possible

areas to check when air or sound values do not meet

expectations. Most fan problems can be pinpointed to

one of these areas:

Bushing Fastener Torque

Bushing Type

Screw Size

Recommended

Torque

JA

10-24

60 in-lbs.

SD/SDS

1/4-20

108 in-lbs.

SK

5/16-18

180 in-lbs.

SF

1/8-16

360 in-lbs.

C

Bushing Set Screw Torque

Bushing Type

Screw Size

Recommended

Torque

SD/SDS

1/4-20

60 in-lbs.

SK

5/16-18

110 in-lbs.

SF

3/8-16

200 in-lbs.

B

Motor Bolt Torque

NEMA Frame

Bolt Size

(Grade 5)

Washers

Size

(Top and

Bottom)

Recommended

Torque (ft-lb)

56-145T

5/16

5/16

18

182-215T

3/8

3/8

31

254U-286TS

1/2

1/2

75

324-365T

9/16

9/16

107

404T-405T

3/4

3/4

267