MACHINE SAFETY

To ensure that work is carried out in the best safety conditions, proceed as follows:

1. Make sure the solution tank is empty. If this is not the case, empty it (read "

2. Make sure the recovery tank is empty. If this is not the case, empty it (read "

3. Sit on the driver’s seat.

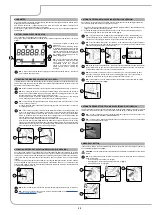

4. Insert the key (1) into the main switch on the control panel. Set the main switch to "I" by turning

the key (1) a quarter turn clockwise (

Fig.1

).

5. Turn the brush head control lever (2) anti-clockwise (

Fig.2

); in this manner the brush head body

will be raised off the floor.

6. Turn the squeegee control lever (3) clockwise (

Fig.3

) to raise the squeegee body off the floor.

7. Set the main switch to “0" (

Fig.5

) by turning the key (1) a quarter turn anti-clockwise. Remove the

key from the instrument panel.

8.

Get off the machine.

CAUTION

: when getting down from the machine, do not place your foot on the scrubbing brush

head or side brush head brush.

9. Grip the back of the seat (4) and turn the seat support plate to its maintenance position (

Fig.5

).

ATTENTION:

to prevent the seat from rotating, insert the retainer (5) into the slot (6) (

Fig.6

).

10. Disconnect the battery connector from the machine's main system connector (

Fig.7

).

11. Grip the back of the seat (4) and turn the seat support plate to the working position.

N.B.

: before rotating the seat support plate, remove the retainer (5).

3

2

1

1

2

3

ON

6

5

5

6

4

4

1

OFF

7

BATTERY MAINTENANCE AND DISPOSAL

For battery maintenance and recharging, respect the instructions provided by the battery manufacturer.

When the batteries reach the end of their service life, they must be disconnected by specialized and

properly trained personnel, and must be subsequently removed from the battery compartment using

suitable lifting devices.

N.B.

: dead batteries are classified as dangerous waste and as such must be delivered to an

authorised body for disposal.

INSERTING THE BATTERIES INTO THE MACHINE

The batteries must be housed in the special compartment beneath the recovery tank and should be

handled using lifting equipment that is suitable in terms of both weight and its coupling system.

DANGER

: make sure that you comply with the accident prevention regulations in force in the

country where you work or with DIN EN 50272-3 and DIN EN 50110-1, before any handling of

the batteries.

CAUTION

: to prevent an accidental short circuit use insulated tools to connect the batteries, and

do not place or drop metal objects on the battery. Remove rings, watches and any clothing with

metal parts that may come into contact with the battery terminals.

The various phases for inserting the batteries in the battery compartment are as follows:

1. Make sure the solution tank is empty. If this is not the case, empty it (read "

").

2. Make sure the recovery tank is empty. If this is not the case, empty it (read "

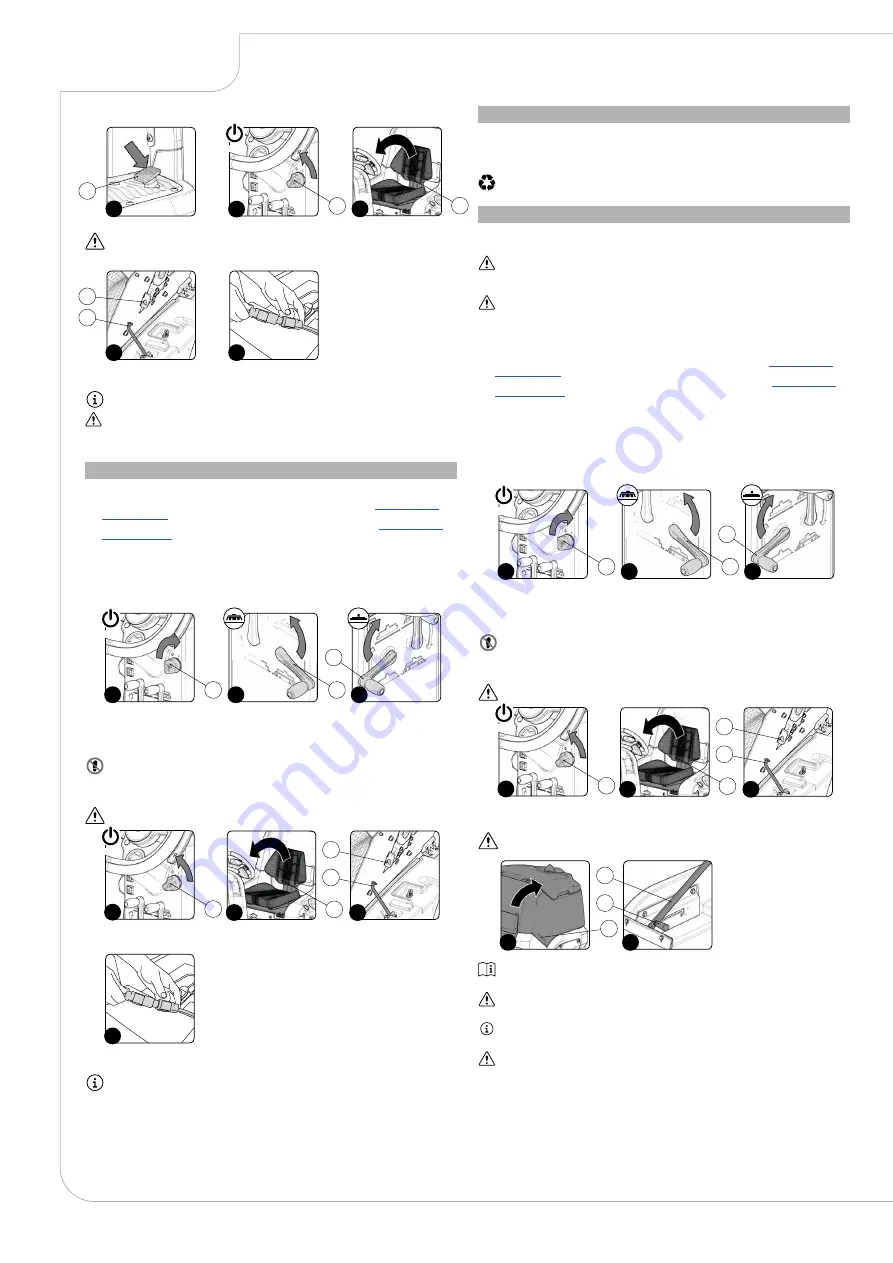

3. Make sure the electronic brake is engaged. If this is not the case, turn the lever (1) clockwise. The

traction gear motor is located on the rear left-hand side of the machine (

Fig.1

)

4. Sit on the driver’s seat.

5. Insert the key (1) into the main switch on the control panel. Set the main switch to "I" by turning

the key (1) a quarter turn clockwise (

Fig.1

).

6. Turn the brush head control lever (2) anti-clockwise (

Fig.2

); in this manner the brush head body

will be raised off the floor.

7. Turn the squeegee control lever (3) clockwise (

Fig.3

) to raise the squeegee body off the floor.

8. Set the main switch to “0" (

Fig.5

) by turning the key (1) a quarter turn anti-clockwise. Remove the

key from the instrument panel.

9.

Get off the machine.

CAUTION

: when getting down from the machine, do not place your foot on the scrubbing brush

head or side brush head brush.

10. Grip the back of the seat (4) and turn the seat support plate to its maintenance position (

Fig.5

).

ATTENTION:

to prevent the seat from rotating, insert the retainer (5) into the slot (6) (

Fig.6

).

11. Grip the handle (7) and raise the recovery tank to the maintenance position (

Fig.7

).

ATTENTION

: to prevent the recovery tank from rotating, grip the handle (8) on the safety stop

lever (9) and position the lever in the second stop slot (

Fig.8

).

N.B.

: for battery maintenance and daily recharging, you must fully respect the indications

provided by the manufacturer or retailer.

CAUTION

: all installation and maintenance operations must be carried out by specialised

personnel.

N.B.

: before installing the battery, clean the battery compartment. Check that the connectors on

the cables supplied are functioning correctly.

ATTENTION

: check that the characteristics of the battery that you are looking to use are

appropriate for the type of work to be performed. Check the battery charge and the condition of

the contacts on the battery.

3

2

1

1

2

3

ON

6

5

5

6

4

4

1

OFF

7

8

7

9

8

10. Grip the back of the seat (5) and turn the seat support plate to its maintenance position (

Fig.6

).

ATTENTION

: to prevent the seat from rotating, insert the retainer (6) into the slot (7) (

Fig.7

).

11. Disconnect the battery connector from the machine's main system connector (

Fig.8

).

12. Grip the back of the seat (5) and turn the seat support plate to the working position.

N.B.

: before rotating the seat support plate, remove the retainer (6).

WARNING

: secure the device according to the directives in force in the country of use, so that it

cannot slide or tip over.

4

4

6

5

5

1

OFF

8

7

6

7

16