4-21

4.11 Setting the Clock

The clock is only visible while in the Last Fault

Display and the purpose of the clock is only to

“Date/Time Stamp” system faults.

1) To set the clock, turn the Main power on.

While the unit is powering up, press the PC

key until a tone occurs. This action will place

the system in the Last Fault Code Mode

(LFC).

2) For 3 seconds: “LF[” will be displayed in the

Cut Window, which is for Last Fault Codes.

The Coag window will display “rX”, (where X

is a numeric value for the software revision).

3) If any errors are stored in memory, the Cut

Window will next display “Err”; the Coag

window will display the error code (a numeric

value); and the Bipolar Window will display

the storage location of that error code.

4) Press PC key: the display will show the DIP

switch settings on the Controller Assembly.

5) Press PC key: the “Date” will be displayed

as MO – DAY – YEAR. Press the Power

Adjustment Keys associated with each win-

dow to set the date. Once the date is set,

Press the STORE” key that is below the

Program Window scroll key to lock the date

in memory.

6) Press PC key: the “Time” will be displayed as

HOUR – MINUTE – SECONDS. Press the

Power Adjustment Keys associated with each

window to set the time. The Cut Window

has either a “P” for PM. or “A” for AM. Once

the time is set, Press the STORE” key that is

below the Program Window scroll key to lock

the time in memory.

7) Press PC key to return to the error code dis-

play. To exit the Last Fault Code Mode, it is

necessary to turn off the main power.

4.12 Troubleshooting

Listed in Table 4.11 are potential errors that

may occur and problem solving ideas for each.

All error codes (Err xxx) can only be cleared by

cycling power. When an error code is displayed,

reset the system to determine if the error can be

cleared with a System Reset or if further service

is required. Error codes are stored as Last Fault

Codes (See Last Fault Codes).

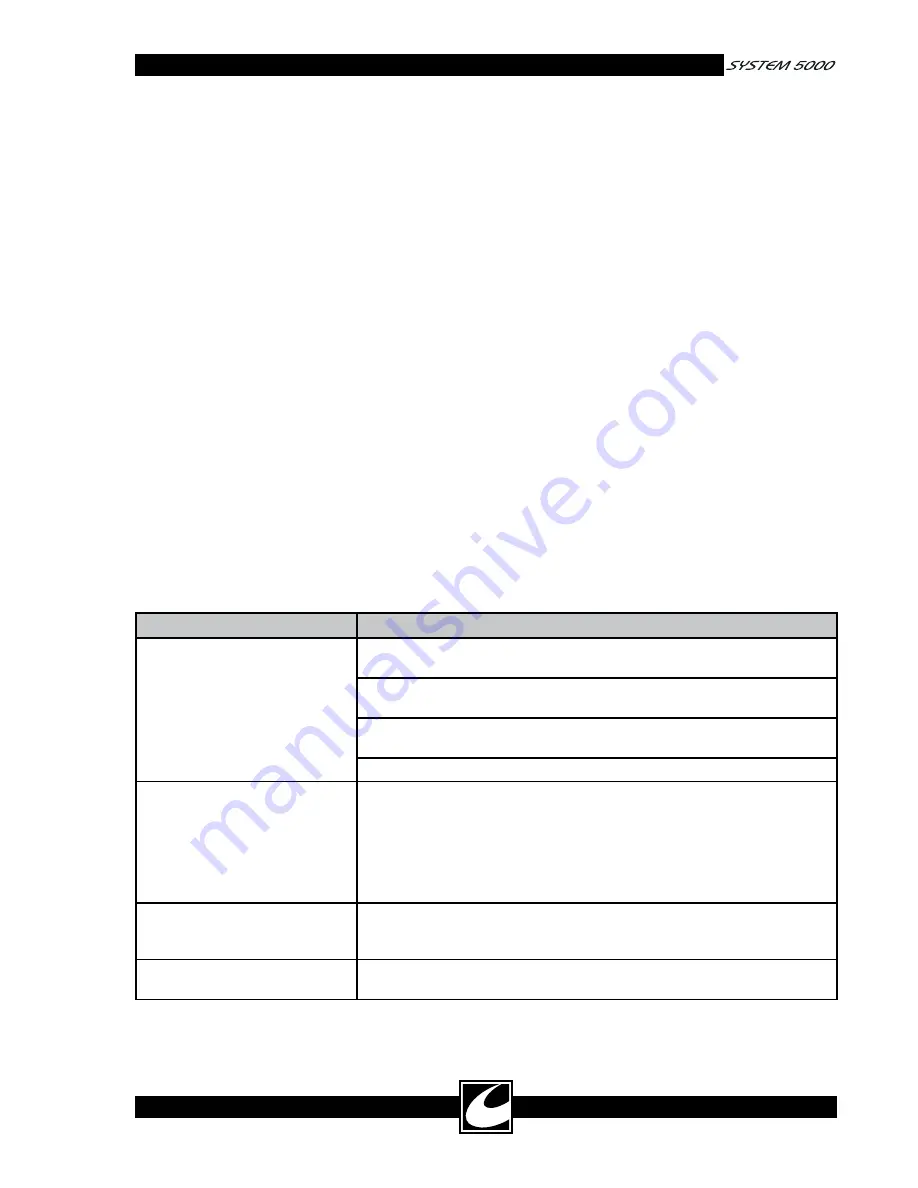

Table 4.11 Troubleshooting

Problem

Possible Cause

Display Panel Blank when System is

Powered on

Verify the power cord is fully seated in the power receptacle on the back of the

System.

With the power cord disconnected, verify fuses are good and are installed prop-

erly in the receptacles on the back panel of the generator.

Remove the top cover and verify that the controller board and all harnesses are

properly seated.

Check the Low Voltage Power Supply for +5V and +15V.

Display:

A[[

xxx

Accessory error – Faulty accessory is connected, a hand controlled accessory

is erroneously actuated, or a footswitch is erroneously actuated. Ensure that

footswitches are not stacked on top one another.

A[[ rH

and

A[[ LH

, indicate

problems with the accessories connected to the right-hand and left-hand Hand

Controlled Monopolar Accessory Receptacles, respectively.

A[[ FS

indicates a

problem with the footswitch connected to either of the Monopolar or Bipolar

Footswitch Connectors.

Display:

A[[ [P

xx

Control Panel error – Check for a faulty push button on the front control panel,

a control panel push button that has been pushed while the unit is being turned

on, or a faulty cable connection between the front panel and the display board.

Display:

LF[

xxx

Last Fault Codes – the Remote Power Control Key was pressed while power was

initialized. The generator must be reset to clear this condition. See section 4.8.