15

ENGLISH

COMUNELLO

®Copyright 2019 - All rights reserved

5 PREPARATION FOR ELECTRICAL

CONNECTIONS

WARNING!

To connect to the network, use a multipolar cable provided by

regulations by the book’s unit.

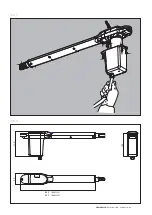

• Perform the manual release as illustrated in heading 4.4.3.

• Remove the plastic cover as shown in FIG. 10.

• Loosen cable gland “G” located on the lower side of the operator FIG.

10.

• Insert the power cable FIG. 11.

• Connect the wires to the terminal board as shown on the adjacent label.

• Connect the earth wire to the terminal eye next to the terminal board

FIG.

11.

(for models of class I).

• Secure the cable by tightening the cable gland.

6 TESTING

Each part of the automation system, e.g. safety edges, photocells,

emergency stop, etc. must be tested; follow the procedures shown in

the instruction manuals supplied with the devices in question. Perform the

following sequence of operations for testing of RAM:

• Check that all the prescriptions in this manual have been followed

scrupulously, with special attention to the matters set down in chapter 1

“Prescriptions”.

• Using the supplied control or stopping devices (key selector switch,

control buttons or radio trasmitters), perform gate opening, closing and

stopping tests and make sure the gate responds correctly to the various

commands.

• Check operation of all the system’s safety devices (photocells, safety

edges, emergency stop, etc.) one by one.

• If potentially hazardous situations caused by movement of the gate leaf

have been eliminated by limitation of impact force, the associated force

must be measured as prescribed in standard EN 12445.

7 PRODUCT MAINTENANCE

Lubrificate the spindle when needed.

Maintenance must be carried out at regular intervals by qualified personnel in

compliance with the provisions of statutory legislation and the regulations in

force. RAM must be serviced at least once every 6 months or after 10.000

operating cycles since the last service.

• Disconnect the operator from all power supplies

• Check all the moving parts and replace any worn parts.

• Check all parts of the automation system for signs of deterioration.

8 SPARE PARTS

Spare parts can be purchased by contacting technical service.

9 DISPOSAL

At the end of its useful life the automation system must be dismantled by

qualified personnel and the materials must be recycled or disposed of in

compliance with the local legislation in force.

10 WARRANTY

fmndjklsvnbdsjkl Fratelli Comunello SpA provides a warranty for 24 months

for the correct functioning of the actuators from the date of manufacture,

provided that the performance specications indicated in the product

instruction manuals are respected. Free of charge repair and replacement

of components that are found to be faulty according to the indisputable

judgment of the company’s technical staff shall be guaranteed at the sole

discretion of Fratelli Comunello Spa, and so excluding any claim for damages

made by others. Warranty material shall be returned to Fratelli Comunello

S.p.a. headquarters carriage paid and will then be shipped to the customer

carriage unpaid. The material found to be faulty and returned to Fratelli

Comunello S.p.a. shall remain property of the Seller. Any cost resulting from

any work needed to repair the defect or to replace the material shall be

charged to the Buyer. No compensation shall be allowed for the period of

device inactivity. Work under warranty does not prolong the warranty period.

The defect of the product shall be reported by the Buyer within 8 (eight) days

from its discovery or from the date of delivery of the goods, under penalty of

invalidation of the warranty. Such claim shall be notied in writing.

Warranty does not cover:

Any product defect or damage that may have been incurred during

transport; any defect or damage arising from any fault and/or from neglect,

inadequacy and misuse of the electrical wiring in the Buyer’s property; any

defect or damage caused by any repairs carried out by non authorised

personnel or by incorrect use/installation (with reference to this, system

maintenance is recommended every 6 months) or if not original spare parts

are used; any defect caused by chemicals or atmospheric conditions. The

warranty does not cover any cost neither for consumable materials nor for

alleged defects or convenient surveys.

Product Features Fratelli Comunello SpA products are subjected to

continue changes and improvements; their technical features and image

may therefore change without previous notice.

Competent court

Since the contract of sale is conrmed by an Order Conrmation drawn up

in Rosà, any such dispute shall be settled by the laws of Italy and by the

court of Vicenza (VI).