Installation, Operating & Maintenance instructions

PAGE 7

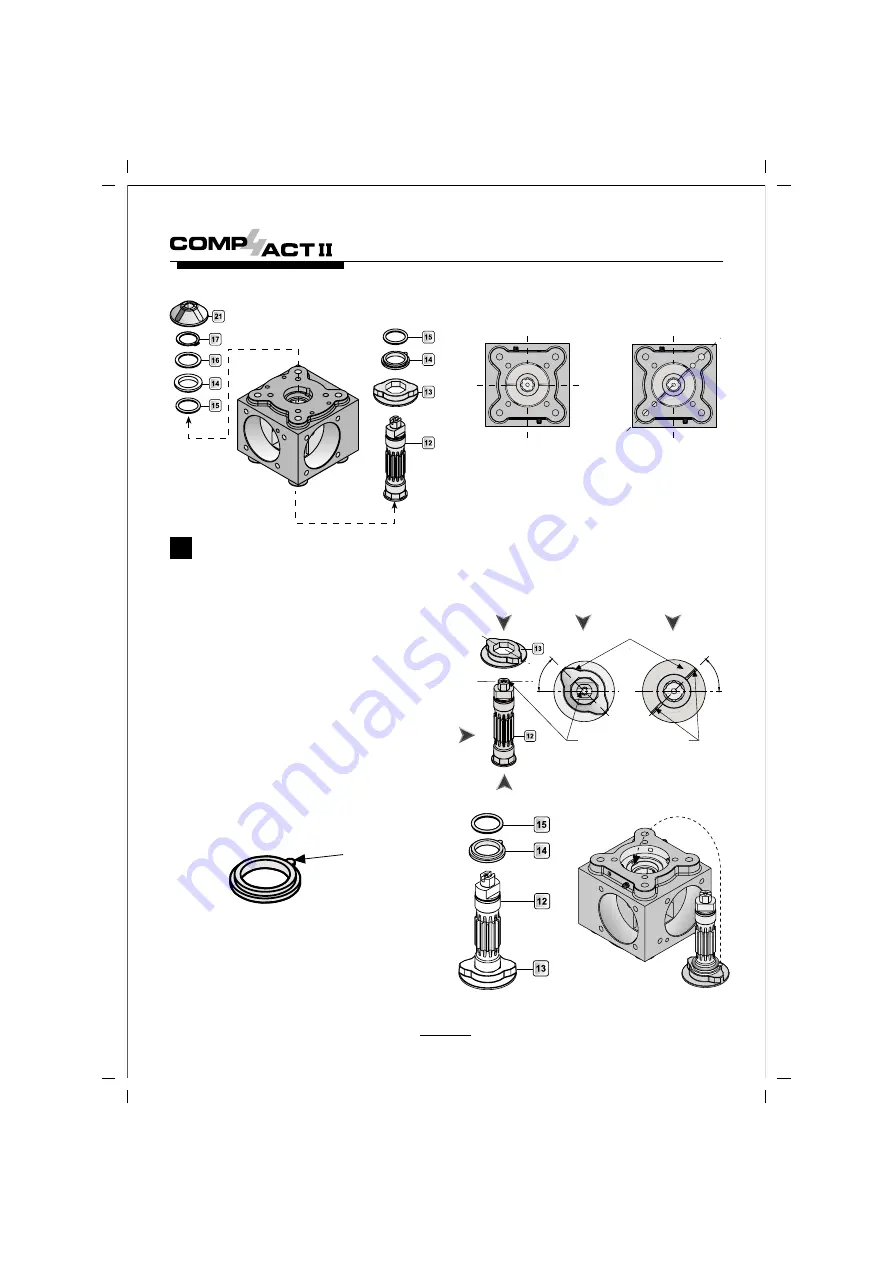

Assembly

6

General

Before performing assembly, clean the grease in the cylinders

and all the actuator parts. Check the cylinder for any scratches.

The surface should be smooth and without any damage,

debris, rust or other contaminants.

Apply grease to all the parts prior to assembly.

6.1

If you have removed the pads, push them back into

their holes as shown in section 4.4.

6.2

If the stop (13) has been removed from the pinion

(12), insert it back making sure the orientation of the

two stop protrusions are at 45

°

to the Namur slot as

shown in the drawing to the right. Use the two grooves

which are cast on the stop bottom plane to identify

the stop orientation.

6.3

Fit the thrust washer (14) and pinion O-ring (15) to the

pinion (12) and stop (13).

For C45 to C75 go to section 8.0

6.4

Insert the pinion assembly into the body. Make sure

that the thrust washer tongue engages to the opposing

groove in the body.

Thrust washer

tongue

6.5

When inserting the pinion to the body, bring the

grooves of the stop perpendicular to the adjustment

screws to ensure correct angle of rotation. Rotate the

pinion CCW until the protrusion flats hit the adjustment

screws and the grooves line up with the threaded

holes as shown below.

Step 1

Grooves perpendicular to

adjustment screws

Step 2

Grooves aligned to

adjustment screws

Bottom View

Bottom View

6.6 Fit the pinion O-ring (15), thrust washer (14) and disc

bearing (16) to the pinion. Make sure that the thrust

washer tongue engages to the opposing groove in

the body.

6.7

Always use a new circlip (17). Insert it on the pinion.

If the pinion does not protrude high enough, make

sure that the bottom thrust bearing tongue has properly

engaged into the body groove and the stop is recessed

in the body. Clip the indicator (21) back on the pinion.

6.8

Place the assembled body with the pinion on the rig

with the adaptor for inserting the pistons back in the

Position the Namur slot horizontaly and the stop protrusions

at 45

°

as shown. The stop has a groove that indicates the

orentation of the protrusions for ease of assembly.

Bottom View

Top View

45

°

45

°

Namur Slot

Stop

Protrusions

Grooves

Top View

Bottom View

Actuator bottom

plane

Trust washer

tongue engages

to groove in body