7

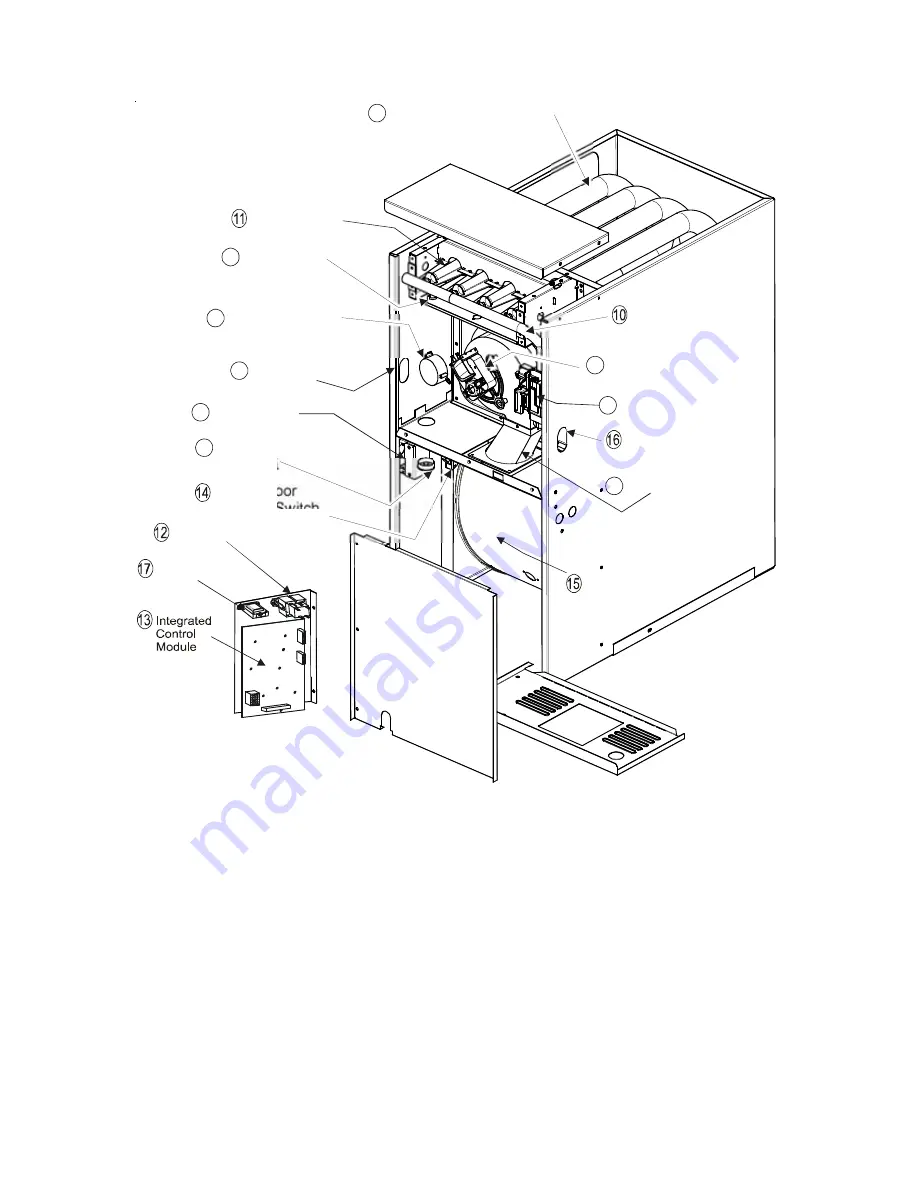

COMPONENT IDENTIFICATION

Flue Pipe Connection

Induced Draft Blower

Gas Line

Entrance

Gas Valve

Rollout Limit

Junction Box

Wiring Harness

Grommet

Gas Manifold

Inshot Burner

3

4

5

6

7

8

9

Blower Door

Interlock Switch

Transformer

Circulator Blower

Inductor

Pressure Switch

2

Gas Line Entrance

(Alternate)

Tubular Heat Exchanger

1

1

Tubular Heat Exchanger

2

Pressure Switch

3

Flue Pipe Connection

4

Induced Draft Blower

5

Gas Line Entrance

6

Gas Valve

7

Rollout Limit

8

Junction Box

9

Wiring Harness Grommet

10 Gas Manifold

11 Inshot Burner

12 Transformer

13 Integrated Control Module

14 Blower Door Interlock Swtich

15 Circulator Blower

16 Gas Line Entrance (Alternate)

17 Inductor