6

REASSEMBLY — GENERAL

The tool is reassembled in the reverse order of disassem-

bly. Clean all parts thoroughly in kerosene and inspect for

damage or wear. Check all bearings for wear which can be

detected by excessive end play and/or roughness which

would indicate a brinelled condition. The rotor blades should

be replaced at every repair cycle if they measure less then

1/4" (6.4mm) at either end. All gear teeth, bearings, and pins

should receive a close inspection and be replaced if neces-

sary.

NOTE: During reassembly of the complete tool, it is impor-

tant that the motor be free. After the tool is completely

assembled, the right angle square drive spindle should turn

freely using a small hand wrench. If the spindle does not turn

freely, the motor should be checked for proper spacing. Do

not run the tool until the spindle turns freely. Failure to do this

could result in damage to motor components.

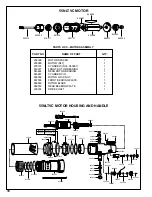

Motor Unit

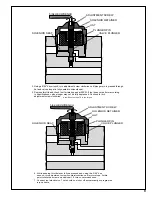

Install the rear rotor bearing into the rear bearing plate.

Make sure the outer bearing race is firmly seated in bearing

plate. Clamp the rotor lightly in the vise with the threaded

end up and slip the rear bearing plate assembly onto the

rotor shaft far enough for the bearing lock nut to start.

Tighten the lock nut until there is approximately .0015"

clearance between the rotor and bearing plate. The outer

bearing race should be firmly seated and the rotor held

forward when checking this clearance.

Pack both rotor bearings with a good grade of No. 2 Moly

grease after assembly of the motor unit.

Gear Train

When installing the spider assembly the idler gears must be

aligned with the pockets machined in the ring gear. Line up

the hole in the ring gear with the hole in the transducer and

install the pin, No. 812164.

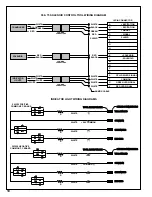

Transducer Wiring Connection

NOTE: Do not bend, strike, push or pull the transducer on

the plastic coated area of the transducer. Connect the cable

connector, No. 202183, to the transducer and wrap the

wiring around the transducer until the cable connector is one

(1) wrap past the connection and then thread the connector

thru the hole in the transducer. Install the transducer on the

motor housing, feeding the connector thru the hole in the

housing. Line up the tangs on the transducer with the

grooves in the housing being careful not to pinch the

connector.

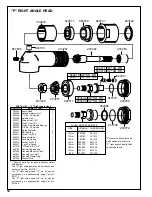

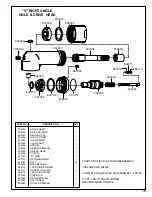

Right Angle Head

During reassembly of the gear train and angle head, all of

the various gears and bearings should receive a generous

amount of NLGI 2-EP grease. The pinion needle bearing

should be slipped onto the pinion gear and then pressed into

the right angle housing until the rear of the bearing is flush

or slightly below the step in the housing.

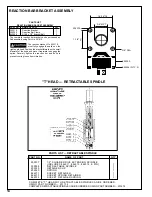

NOTE: During reassembly of the "T" right angle head, the

bearing cap, No. 867509, should be torqued to 100-110 ft.

lbs. Also, the bearing cap lock screw, No. 867997, should be

torqued to 10 in. lbs. minimum.

Pour a few drops of 10W machine oil into the air inlet after

complete assembly to ensure immediate lubrication of all

motor parts when air is applied.

SAFETY CHECK

After repair or replacement of parts, tools equipped with an

automatic shut-off device should be tested to verify that it is

functioning properly. The torque setting entered into the

torque control monitor must not exceed maximum torque

range or tool will stall and not shut-off.

SERVICE INSTRUCTIONS

Must be replaced if

7/32" (5.6mm) or less

at either end.

SOFT

JAWED

VISE

.0015"

Clearance

Содержание 55NLTVC Series

Страница 21: ...21...

Страница 22: ...22 NOTES...

Страница 23: ...23 NOTES...

Страница 24: ...24 670 Industrial Drive Lexington SC 29072 Phone 803 359 1200 Fax 803 359 2013...