5

SERVICE INSTRUCTIONS

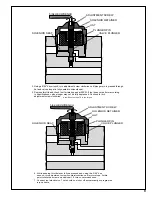

DISASSEMBLY — GENERAL

Disconnect tool from air supply. Clamp the right angle head

in a vise and loosen (left hand threads) the motor housing.

Hold the tool in a vertical position with the right angle head

up. Unscrew (left hand threads) and remove the head, and

transducer housing from the motor housing. Disconnect the

wire connector, No. 202183, at the transducer and remove

the transducer and gear train from the motor housing. Slip

the complete motor unit out the front of the housing.

Clamp the angle head in the vise and unscrew (left hand

threads) the right angle housing lock nut, No. 867521, to

remove the transducer housing.

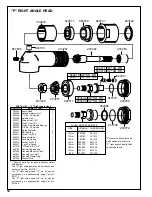

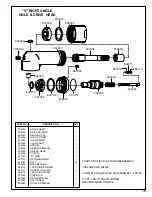

"M" Right Angle Head

Using a suitable spanner wrench, unscrew (left hand threads)

the bearing cap, No. 864396. Remove the square drive

spindle, No. 867643, ball bearing, No. 842517, and driven

gear by clamping the square drive in the vise. Drive the right

angle housing, No. 867506, away from the square drive

using a soft-faced mallet. The ball bearing can now be

removed by pressing the square drive end of the spindle

through the bearing I.D. Press the smaller end of the spindle

through the gear to remove the driven gear. Screw a 1/40

NC bolt into the pinion gear. Clamp the head of the bolt in the

vise and use a soft-faced mallet to drive the housing off the

gear. If this method fails, it will be necessary to use a suitable

puller.

"P" Right Angle Head

Using a suitable wrench, unscrew (left hand threads) the

bearing cap, No. 203250. Remove the square drive spindle,

No. 203249, ball bearing, No. 842517 and driven gear, No.

203251, by clamping the square drive in the vise. Drive the

right angle housing, No. 203247, away from the square

drive using a soft-faced mallet. Remove the spindle retainer

nut, No. 203248, with a wrench. The ball bearing can now

be removed by pressing the square drive end of the spindle

through the gear to remove the driven gear. Screw a 1/40

NC bolt into the pinion gear. Clamp the head of the bolt in

the vise and use a soft-faced mallet to drive the housing off

the gear. If this method fails, it will be necessary to use a

suitable puller.

"T" Right Angle Head

Loosen the bearing cap lock screw, No. 867997, and

unscrew (left hand threads) the bearing cap, No. 867509.

Remove the square drive spindle, No. 867510, ball bearing,

No. 867547, and driven gear by clamping the square drive

in the vise. Drive the right angle housing away from the

square drive using a soft-mallet. Press the square drive end

of the spindle through the bearing I.D. to remove the ball

bearing. The driven gear may be removed by pressing the

smaller end of the spindle through the gear. Remove the

grease plug, No. 867546, and , using a suitable driver, drive

the pinion gear out of the right angle housing.

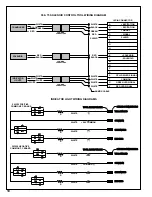

Gear Train 2, 3, 4, 6, & 10

Important: Do not bend, strike, push or pull in any way that

will cause strain in the plastic coated area of the transducer.

Remove the gear train from the front of the ring gear.

Remove the retainer ring and ball bearing. Drive roll pin, No.

812164, in far enough to clear the ring gear and slip the ring

gear off the transducer.

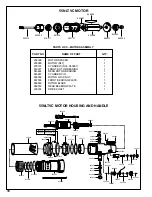

Gear Train

Important: Do not bend, strike, push or pull on the plastic

coated area of the transducer. Drive roll pin, No. 812164, in

far enough to clear the ring gear. Remove the ring gear and

align the idler gears with the pockets machined in the ring

gear. Slip the spider assembly out the rear of the ring gear.

Remove the retainer ring and ball bearing and drive the roll

pin into the bearing bore.

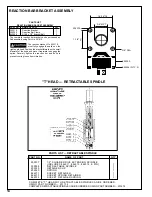

Motor Unit

Clamp the cylinder lightly in a vise with the gear end of the

rotor up. Note: Rotor pinion, No. 867524, used on the and

models should be removed at this time. Drive the rotor out

of the front rotor bearing, No. 619377. Be careful not to

damage the rotor. The front bearing plate, No. 867536,

cylinder, and rotor blades, No. 203219, can now be re-

moved from the rotor. Clamp the rotor in the vise with the

rear bearing plate up. After unscrewing the bearing lock nut,

No. 865352, the rotor can be driven out of the rear rotor

bearing.

Motor Housing

Clamp the flats of the motor housing in the vise and use a

strap wrench to unscrew the handle, No. 202182. Discon-

nect the wire bundle from the cable connector, No. 202183.

Remove solenoid retainer, No. 203369, with wrench and

remove solenoid, No. 203363. Remove retainer ring, No.

203053 and rear light ring, No. 203263. Unplug P.C. Board,

and remove from rear of tool. Remove set screw, No.

813315 and remove front light ring, No. 203262. Remove

exhaust deflector, No. 203261, exhaust screen, No. 202177,

and muffler, No. 202012, from the rear of the housing.

Remove throttle valve cap, No. 864531, valve cap, No.

203380 and shut-off valve cap, No. 203550 with screw-

driver to check seals and "O"-rings.

Содержание 55NLTVC Series

Страница 21: ...21...

Страница 22: ...22 NOTES...

Страница 23: ...23 NOTES...

Страница 24: ...24 670 Industrial Drive Lexington SC 29072 Phone 803 359 1200 Fax 803 359 2013...