16

B. Installing the Welding Wire

NOTE: These machines are designed to accept either the Clarke ‘Mini’ or 5kg wire

spools of mild steel, stainless steel or aluminium according to the type of metal you

wish to weld. Mini Mild Steel wire spools are supplied with the machine..... others

must be purchased separately. See ‘Accessories’ or your Clarke dealer for full

details.

A. Loose Components

MIG 150TE

ASSEMBLY & INSTALLATION

Fig.1

1.

IMPORTANT: Ensure that the gas

and electrical supplies are

disconnected.

2.

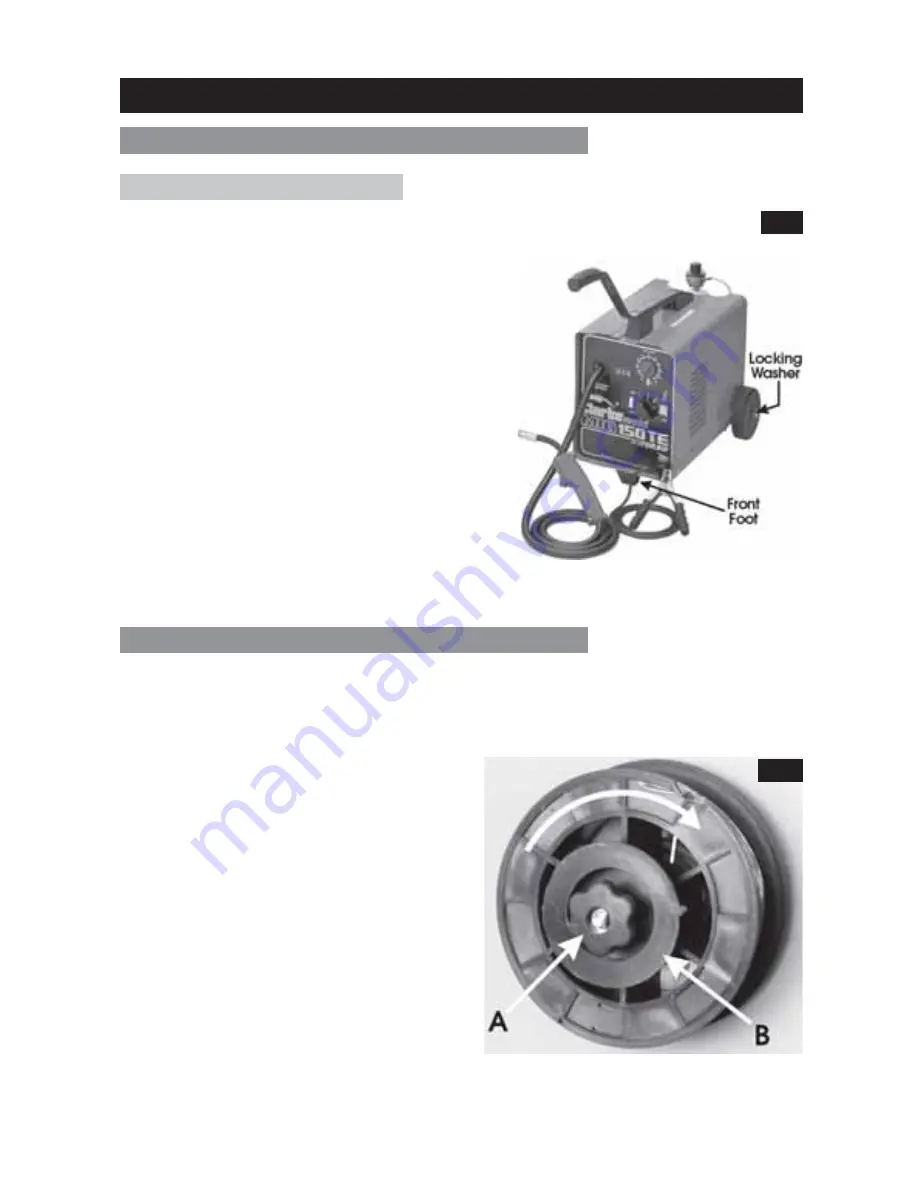

(Ref. Fig. 2).

To fit the wire spool, firstly

open the side compartment by

pulling the cover upwards.

Unscrew and remove the plastic knob

(A), followed by the spring and collar

B) and finally the wire spool. (If the

spool is already fitted during initial

assembly, remove the plastic

covering).

3.

Slide the spool on to the shaft, ensuring that it sits snugly, and the direction of feed of

the wire is in the direction of the arrow.

Insert the axle through the holes in the rear base

of the machine, then attach the wheels,

securing them by pushing the star locking

washers provided, on to the axle, using a piece

of tube or an old socket, ensuring the centre tines

of the washer face outwards.

Lay the machine gently on its side and attach

the foot to the front base using the screw and

washer provided.

Attach the handle to the top of the machine by

slotting it into place and securing with the screws

provided. Slide the handle extension into the handle

and secure with the screw provided.

The gas bottle is secured to the machine using the

large worm drive fastening band which is threaded

through the opening provided on the rear panel

of the machine.

Fig.2