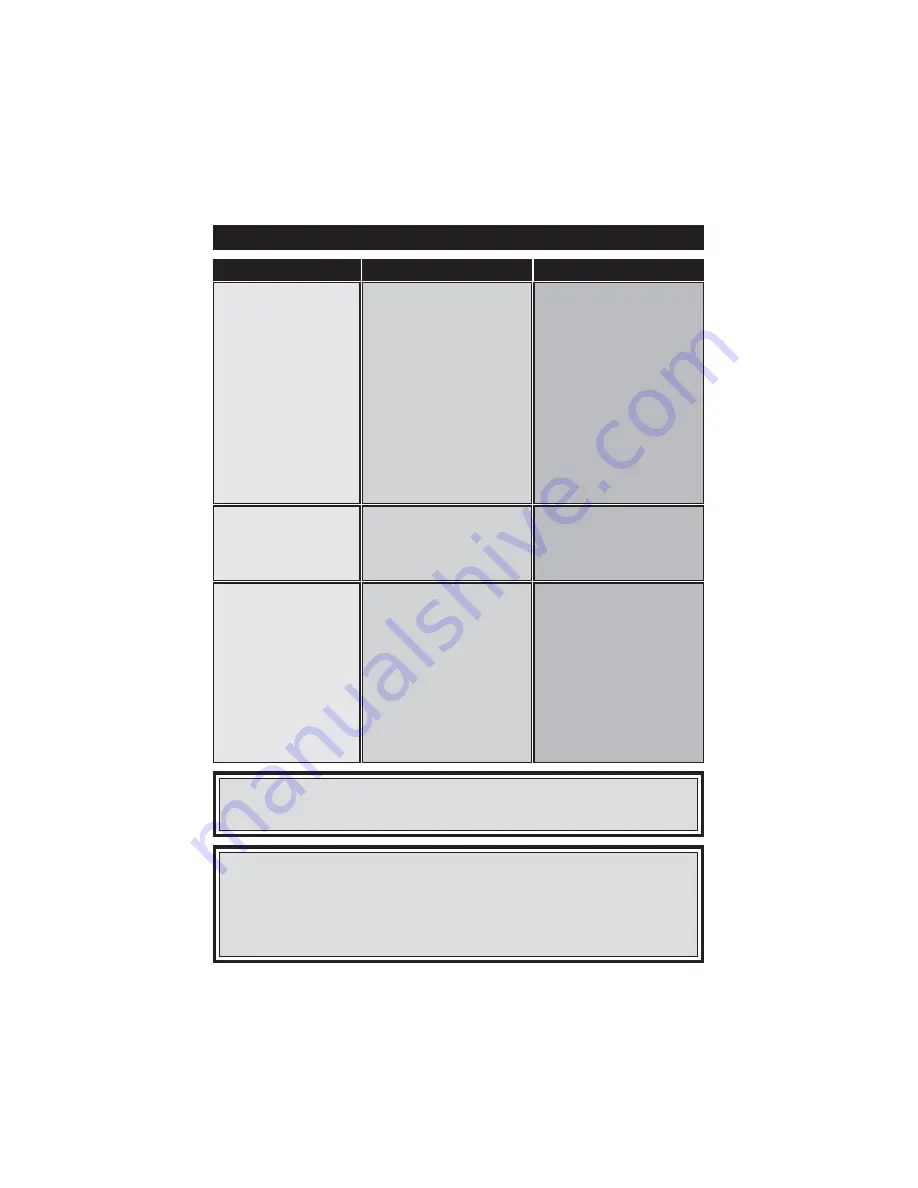

Trouble Shooting

Problem

Probable Cause

Remedy

Log fails to split.

Incorrect positioning of the

log.

Reposition the log.

Log exceeds permitted

dimensions or wood is too

hard or knotty for the

capacity of the machine.

Use logs of the correct

specifications.

Wedge not cutting.

Check the splitting wedge

and sharpen if necessary.

Oil Leak

Locate the leak and rectify,

if necessary, contact your

nearest Clarke dealer.

Log pusher advances

jerkily and/or vibrates

badly.

Air in hydraulic system.

Check oil level. Top up if

necessary. If problem

persists, consult your

nearest Clarke dealer.

Oil leaks.

Leaking from the tank.

Check the bleed screw has

been unscrewed before

operating the machine.

Washer/seal on plug/

dipstick worn or damaged.

Fit replacement washer.

Worn or damaged oil seals.

Fit new oil seals, consult

your nearest Clarke dealer.

PARTS & SERVICE TEL: 020 8988 7400

or e-mail as follows:

PARTS: [email protected]

SERVICE: [email protected]

IMPORTANT:

T

he use of parts other than CLARKE replacement parts may result in safety hazards,

decreased tool performance and may invalidate your warranty.

Log pusher advances

jerkily or with strong

vibrations.

-14-

Содержание Log Buster 3

Страница 15: ...Parts Diagram 15...

Страница 18: ...18...