11

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

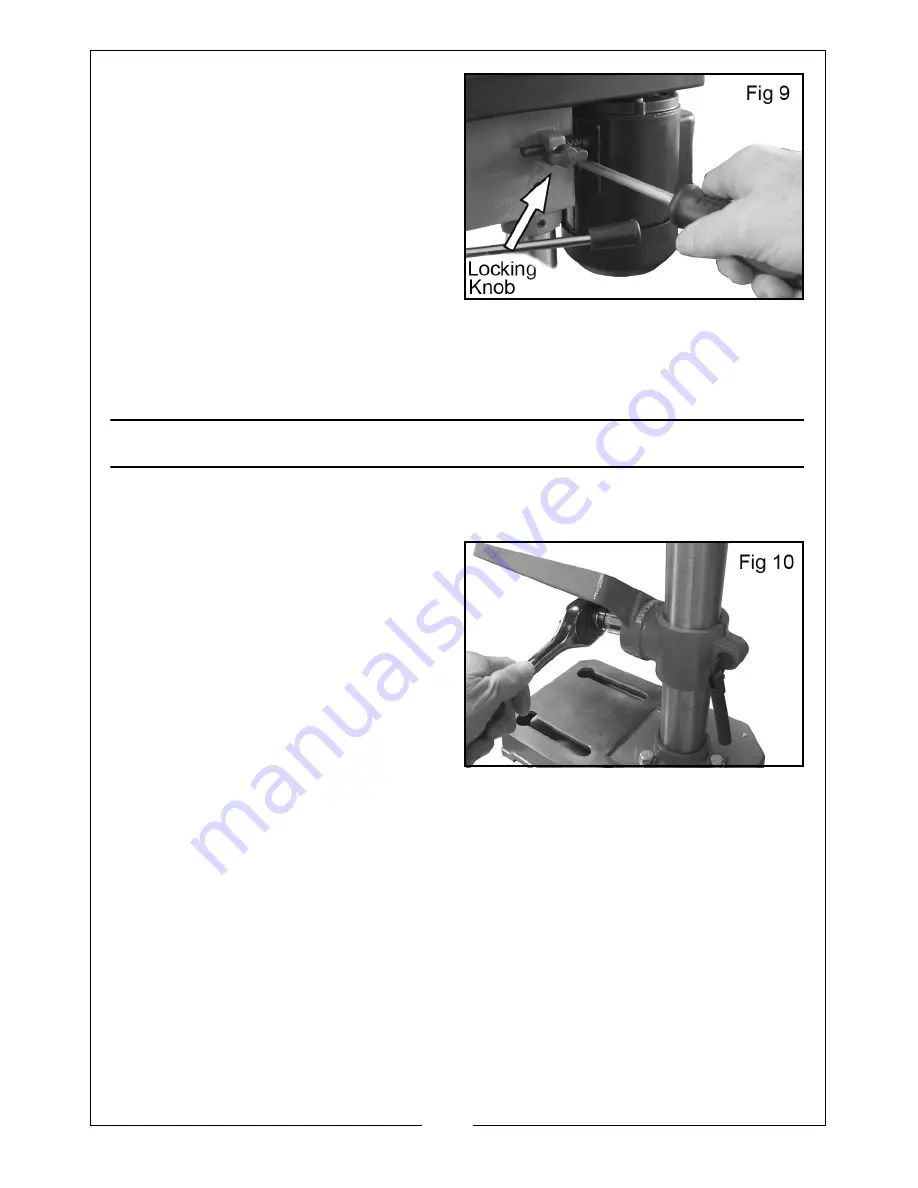

3. Lever the motor/bracket, away

from the head, so that tension is

applied to the belt.

4. Lock the motor in this position

using the locking knob.

NOTE:

If the belt slips whilst drilling,

re-set the belt tension.

IMPORTANT: When closing the cover, check the operation of the safety

switch. It should operate as soon as the cover is unfastened. Undo the

switch actuator fixing screw shown in Fig 8 and adjust if necessary.

SETTINGS AND ADJUSTMENTS

TABLE

The table may be raised, lowered or

swivelled around the column, by

slackening off the table support

locking handle, adjusting

accordingly and re-tightening the

handle.

It may also be tilted by loosening the

bolt beneath the table, tilting the

table to the required position and

re-tightening the bolt shown in Fig 10.

A bevel scale is provided on the table mounting, (measured in degrees), to

assist in setting the required angle. However, for greater accuracy, the use of a

protractor is recommended.

For all normal operations, the table should be set to 0°. To check to ensure the

drill is entirely perpendicular to the table, install a large drill bit in the chuck,

place a set-square on the table, and bring it up to the drill. Adjust the table if

necessary, so that it is perfectly level.