Civemasa Implementos Agrícolas

44

GDFH

Disk harrow maintenance

Maintenance

• In disuse period wash the harrow, repair the damaged paintwork, protect the disc

blades with oil, lubricate all grease fittings and store the equipment in a covered and dry

location, avoiding contact with the soil.

• The disc blades should be replaced as soon as you notice a low-income thereof,

characterized mainly by the reduction in diameter, cut loss and other damages to which

they are subjected during working.

• After 24 operation hours, check if the bolts are still tightened. To assure a greater

performance and to avoid unecessary wear and rupture, retighten the bolts every so often.

• Make sure all moving parts have no wear. If necessary, replace them.

• Replace the missing or damaged safety decals. Civemasa can provide these decals

under request just being necessary to inform their serial numbers. The operator must know

the need to keep each decal in good condition and on its proper place. The operator also

have to know that the lack of safety may be harmful and the higher chance of an accident

if the instructions are not being followed.

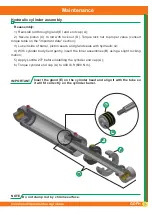

IMPORTANT When uncoupling the equipment from the tractor, lift it, place the locks

(A) on the cylinders, lower the disk harrow until it touches the locks

and place the parking jack with a pin and cotter pin.

If it is necessary to completely lower the equipment, do not place the

locks and neither the pin on the parking jack, as such act may cause

damages to the jack itself.

A

A

NOTE Use Civemasa original parts only.

Содержание GDFH

Страница 1: ...OPERATOR S MANUAL GDFH GDFH ...