18

5.4 Maintenance of the Speed Controller:

CAUTION

Only a qualified electrician is allowed to do the maintenance for the controller.

WARNING!

There are no user serviceable parts inside the controller. No attempt should be made to open, repair,

or otherwise modify the controller. Doing so may damage the controller and will void the warranty.

CLEANING

It is recommended that the controller be kept clean and dry and that its fault history file be checked and

cleared periodically.

Periodically cleaning the controller exterior will help protect it against corrosion and possible electrical

control problems created by the dirt, grime, and chemicals that are part of the operating environment and

that normally exist in battery powered systems.

Please use the following cleaning procedure for routine maintenance:

1) Turn the power key to OFF position.

2) Cut off power by disconnecting the battery.

3) Discharge the capacitors in the controller by connecting a load (such as a contactor coil or a horn)

across the controller’s B+ and B- terminals.

4) Remove any dirt or corrosion from the connector areas. The controller should be wiped clean with a

moist rag. Dry it before reconnecting the battery. The controller should not be subjected to pressured

water flow from either a standard hose or a power washer.

5) Make sure the connections are tight, but do not over-tighten them.

Faulty History File

The handheld programmer (ordered separately) can be used to access the controller’s fault history file. The

programmer will read out all the faults the controller has experienced since the last time the history file was

cleared. Faults such as contactor faults may be the result of loose wires; contactor wiring should be

carefully checked. Faults such as over temperature may be caused by operator habits or by overloading.

After a problem has been diagnosed and corrected, it is a good idea to clear the fault history file. This

allows the controller to accumulate a new file of faults. By checking the new history file at a later date, you

can readily determine whether the problem was in deed fixed.

Or checking the problems according to the flashing of the STATUS light on the top of the controller, please

refer to the details mentioned in our service manual which is available separately.

Please contact your local dealer or a qualified electrician to work on the problems related to the

motor, controller or electrical system of the vehicle when you are not able to fix them.

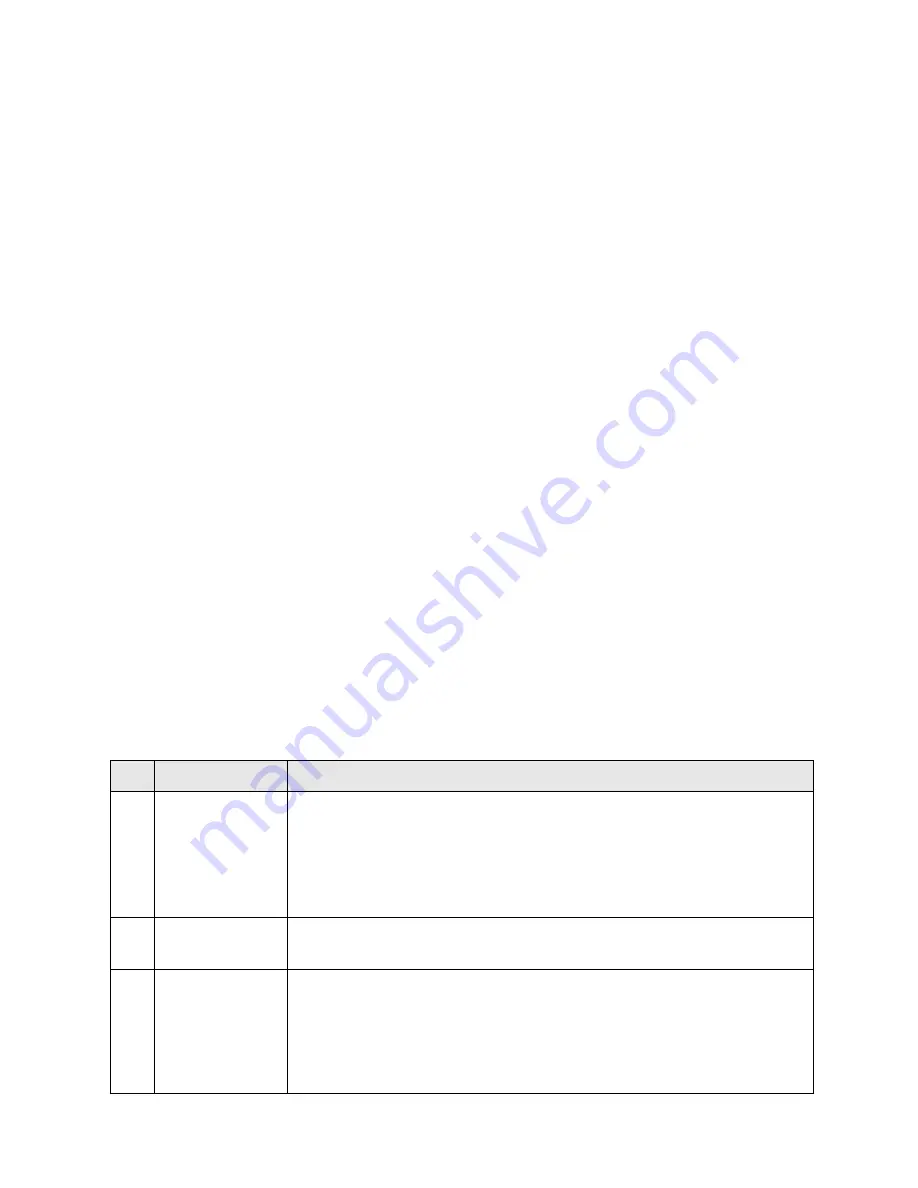

Main malfunction symptoms and possible causes of the controller

Item Symptoms

Possible Causes

1

The vehicle

cannot start

1) The controller does not have power

2) No signal is transmitted to the controller

3)

The contacting point of the contactor is stuck

4) The controller or the motor is damaged

5) The Motor encoder is not programmed properly or is damaged

6) The Motor or controller is over-temperature

7) The Electromagnetic brake locked

2

The vehicle can

only move in one

direction

1) The F/R switch is damaged or disconnected from the harness.

3

The vehicle

cannot reach

maximum speed

1) The battery is going to run out.

2)

The hand brake is not released or the brake shoe doesn’t release.

3)

The accelerator failed

4)

The Controller failed

5)

Too much loading

6) The Motor or controller is over-temperature

7)

The Motor encoder failed

Содержание Street Legal

Страница 6: ...6 2 Controls 1 Schematic Figure of controls Fig 1 Fig 2 Fig 3 ...

Страница 27: ...27 ...