18

Shut Down Procedure

A) Shut Engine off by turning key to

“0”

B) Set Control Panel Main Panel switch to

“

OFF ”

.

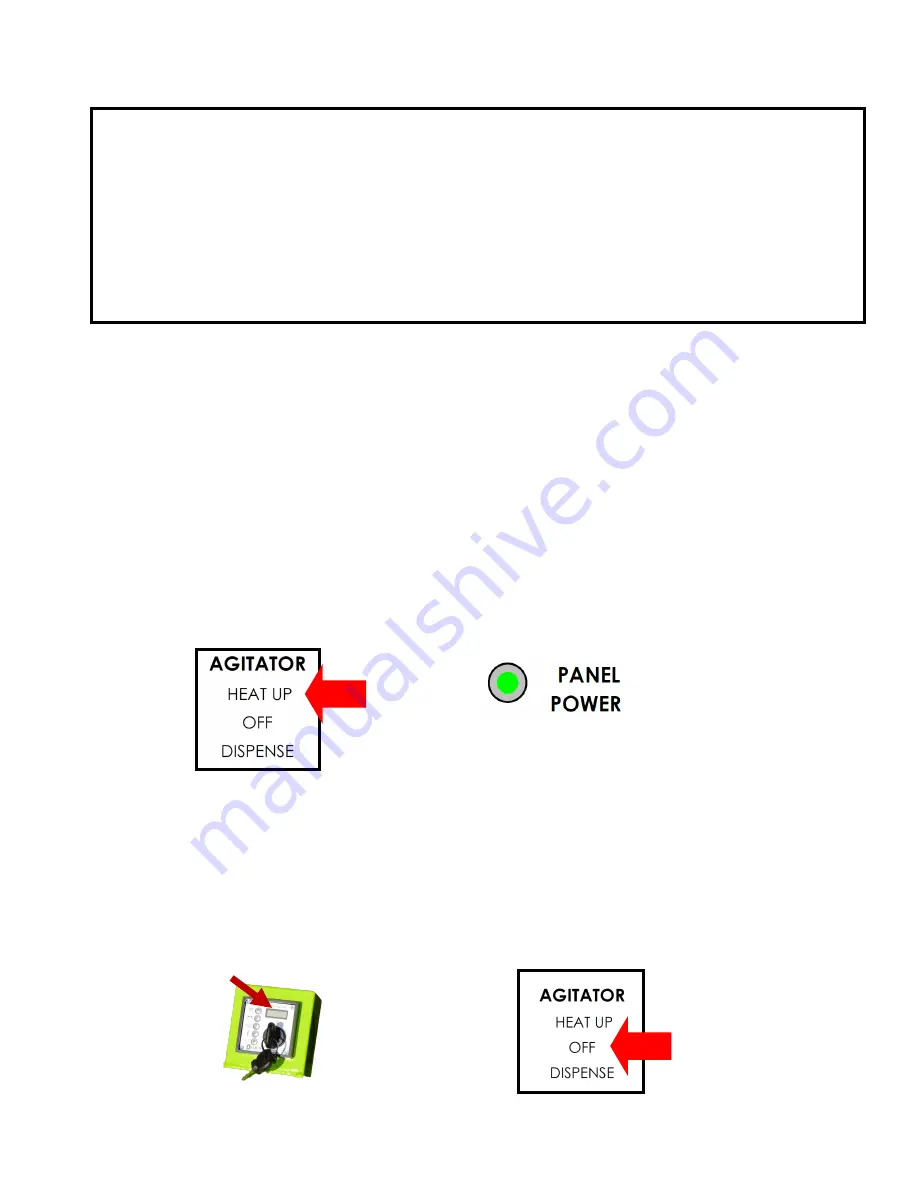

C) Put the Agitator Directional Switch to the

“OFF”

position.

D) Ensure all valves are closed going to the tool box and trough

burners.

Cool Down Procedure

A) Close the 2 propane needle valves (Near the Tool Box Heater and trough), 3 ball

valves (2 at the propane tank and the 3rd at the back of the machine on the

passenger side), and close the propane tank.

B) Set Control Panel Main Panel switch to

“OFF”

. Indicated by the Panel Power

LED being unpowered.

C) Put the agitator into the

“Heat Up”

position.

D) Let machine run for 15 to 30 minutes..

E) Put the Agitator Directional Switch to the

“OFF”

position.

APPLYING MASTIC

With Start Up procedure complete, you are ready to begin sealing

A) Turn Agitator to the

“DISPENSE”

Position

B) Open Material Gate at rear of machine.

C) Let material flow onto heated chute.

D) Scrape material from chute into Desired Tool.

Содержание ME3

Страница 13: ...13 Inside the Main Control Panel box is a Sub Control Panel See the next page for detailed explanation of use ...

Страница 15: ...15 Sub Control Panel Controls and Their Functions 1 2 3 4 6 7 8 5 ...

Страница 34: ...34 Trailer Wiring Diagram ...

Страница 39: ...39 Burner Internal Wiring Diagram ...

Страница 43: ...43 Mastic Hydraulic Manifold Components ...

Страница 44: ...44 Hydraulic Schematic ...

Страница 49: ...49 Miscellaneous Parts 28 29 30 30 ...

Страница 51: ......

Страница 52: ...52 2601 Niagara Lane Plymouth MN 55447 763 557 1982 800 328 3874 Fax 763 557 1971 ...