HD Manual Arc Welders

©2000 CIGWELD All rights reserved

28

13.1 Cleaning the Welding Power Source

Refer to

WARNING 5

. To clean the Welding Power Source, open the enclosure and use a

vacuum cleaner to remove any accumulated dirt, metal filings, slag and loose material. Keep

the shunt and lead screw surfaces clean as accumulated foreign material may reduce the

welders output welding current.

CAUTION 3

Do not use compressed air to clean the Welding Power Source. Compressed air can force metal particles

to lodge between live electrical parts and earthed metal parts within the Welding Power Source. This may

result in arcing between this parts and their eventual failure.

14. BASIC TROUBLESHOOTING

WARNING 6

There are extremely dangerous voltage and power levels present inside this product. Do not attempt to

open or repair unless you are a qualified electrical tradesperson and you have had training in power

measurements and troubleshooting techniques.

If major complex subassemblies are faulty, then the Welding Power Source must be returned to an

Accredited CIGWELD Service Agent for repair. The basic level of troubleshooting is that which can

be performed without special equipment or knowledge.

14.1 Welding Problems

FAULT

CAUSE

REMEDY

1 Gas pockets or voids in

weld metal (Porosity).

A

B

C

Electrodes are damp.

Welding current is too high.

Surface impurities such as oil,

grease, paint, etc.

A

B

C

Dry electrodes before use.

Reduce welding current.

Clean joint before welding.

2 Crack

occurring

in

weld metal soon after

solidification

commences

A

B

C

Rigidity of joint.

Insufficient throat thickness.

Cooling rate is too high.

A

B

C

Redesign to relieve weld joint of

severe stresses or use crack

resistance electrodes.

Travel slightly slower to allow

greater build up in throat.

Preheat plate and cool slowly.

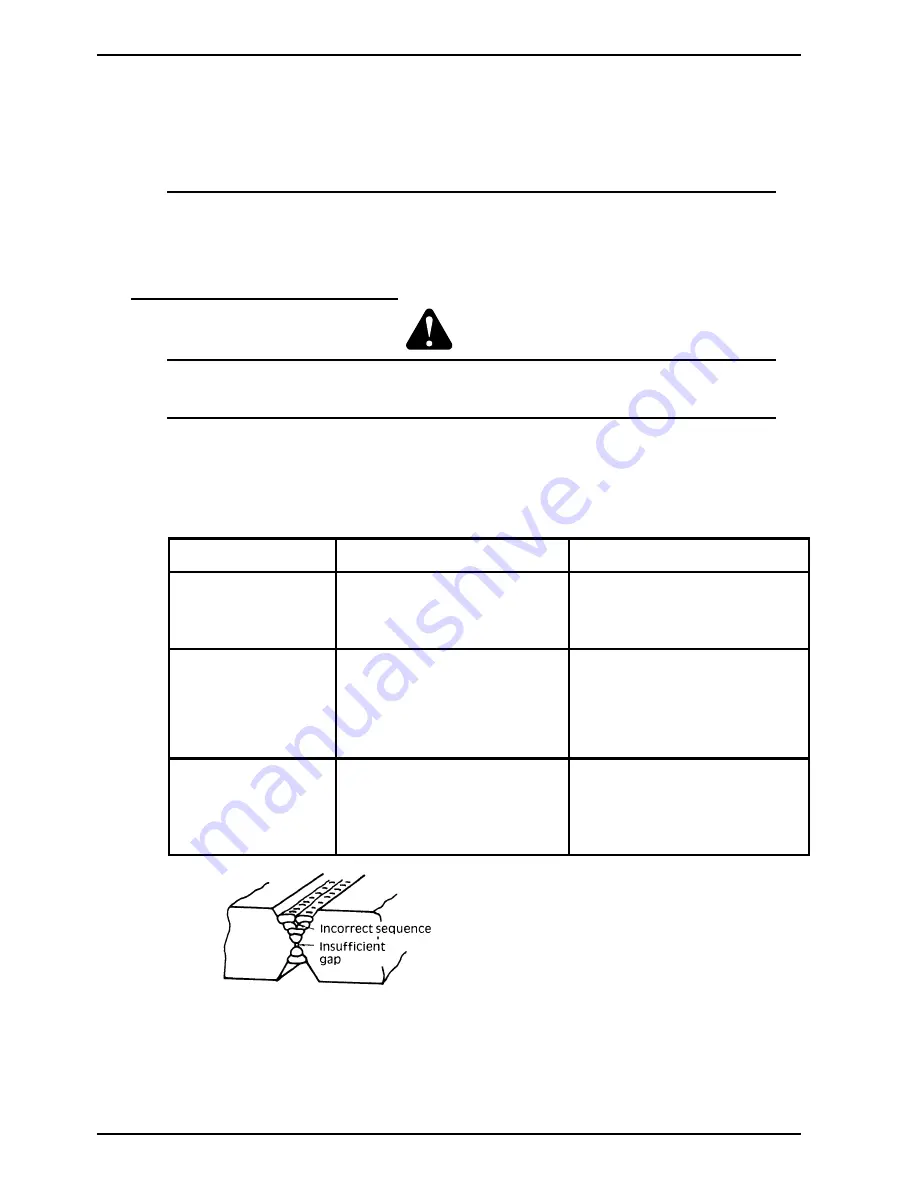

3 A gap is left by failure

of the weld metal to fill

the root of the weld.

A

B

C

Welding current is too low.

Electrode too large for joint.

Insufficient gap.

A

B

C

Increase welding current

Use smaller diameter

electrode.

Allow wider gap.

D Incorrect sequence.

D Use correct build-up sequence.

Figure 28 - Example of insufficient gap or incorrect sequence