HD Manual Arc Welders

©2000 CIGWELD All rights reserved

18

9. ARC WELDING ELECTRODES

Metal arc welding electrodes consist of a core wire surrounded by a flux coating. The flux coating is

applied to the core wire by an extrusion process.

The coating on arc welding electrodes serves a number of purposes:

a) To provide a gaseous shield for the weld metal, and preserve it from contamination by

the atmosphere whilst in a molten state.

b) To give a steady arc by having ‘arc stabilisers’ present, which provide a bridge for

current to flow across.

c) To remove oxygen from the weld metal with ‘deoxidisers’.

d) To provide a cleansing action on the work piece and a protective slag cover over the

weld metal to prevent the formation of oxides while the metal is solidifying. The slag

also helps to produce a bead of the desired contour.

e) To introduce alloys into the weld deposits in special type electrodes.

9.2 Types

of

Electrodes

Arc Welding electrodes are classified into a number of groups depending on their applications.

There are a great number of electrodes used for specialised industrial purposes which are not of

particular interest for everyday general work. These include some low hydrogen types for high

tensile steel, cellulose types for welding large diameter pipes, etc.

The range of electrodes dealt with in this publication will cover the vast majority of

applications likely to be encountered; are all easy to use and all will work on even the most

basic of welding machines.

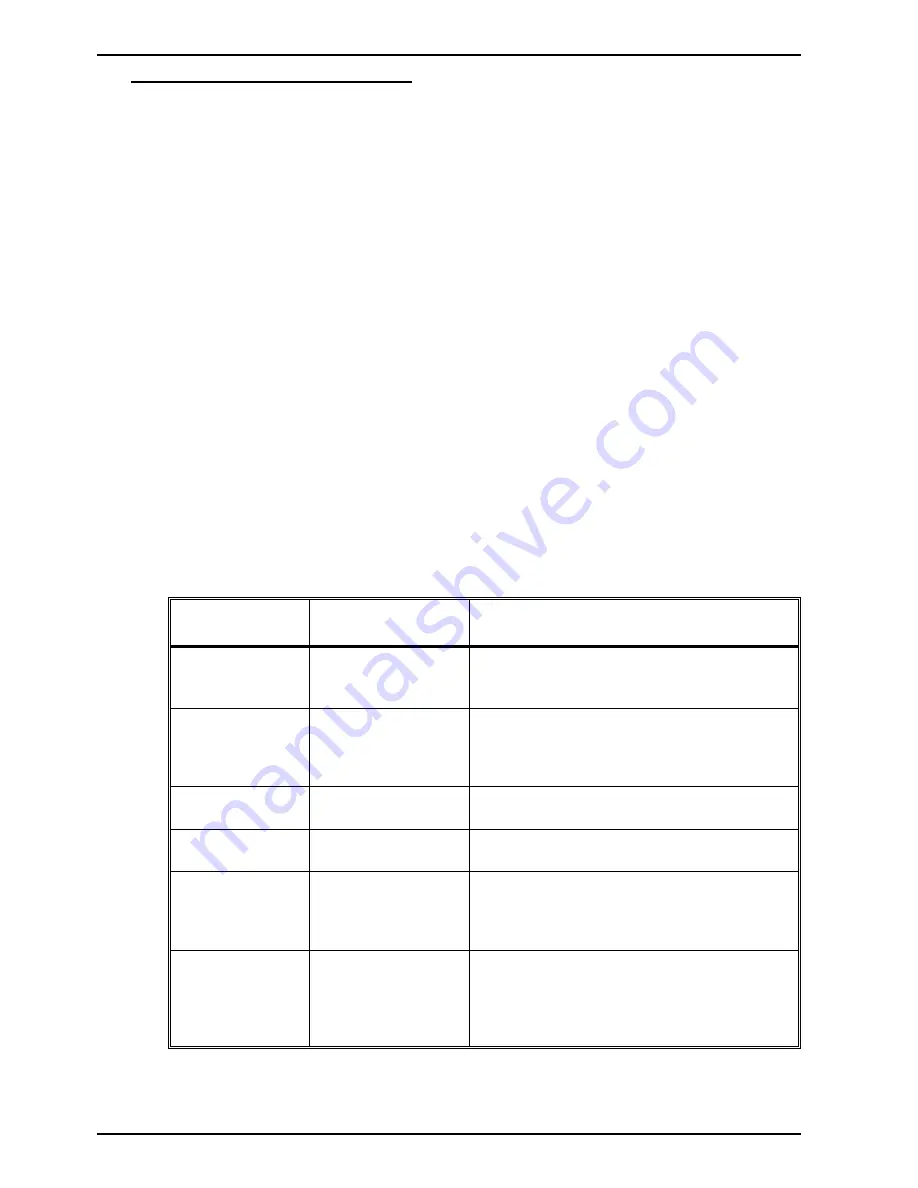

Metals being

joined

CIGWELD

Electrode

Comments

Mild steel

Satincraft 13

(AS/NZS E4113-0)

Ideal electrodes for all general purpose work.

Features include out standing operator appeal,

easy arc starting and low spatter.

Mild steel

Ferrocraft 21

(AS/NZS E4818-2)

All positional electrode for use on mild and

galvanised steel furniture, plates, fences, gates,

pipes and tanks etc. Especially suitable for

vertical-down welding.

Cast iron

Castcraft100

Suitable for joining all cast irons except white cast

iron.

Stainless steel

Satincrome 318-16

(AS/NZS E316L-17)

High corrosion resistance. Ideal for dairy work,

etc. On stainless steels.

Copper, Bronze,

Brass, etc.

Bronzecraft

(AS/NZS E6200-A2)

Easy to use electrode for marine fittings, water

taps and valves, water trough float arms, etc. Also

for joining copper to steel and for bronze overlays

on steel shafts.

High alloy steels,

Dissimilar metals,

Crack resistance,

All hard-to-weld

jobs.

Weldall

(AS/NZS E312-17)

Weldall does truly what its name states. It will

weld even the most problematical jobs such as

springs, shafts, broken joins mild steel to stainless

and alloy steels.

Not suitable for Aluminium.

Table 2 - Types of Electrodes