PXR

Installation Instructions

26

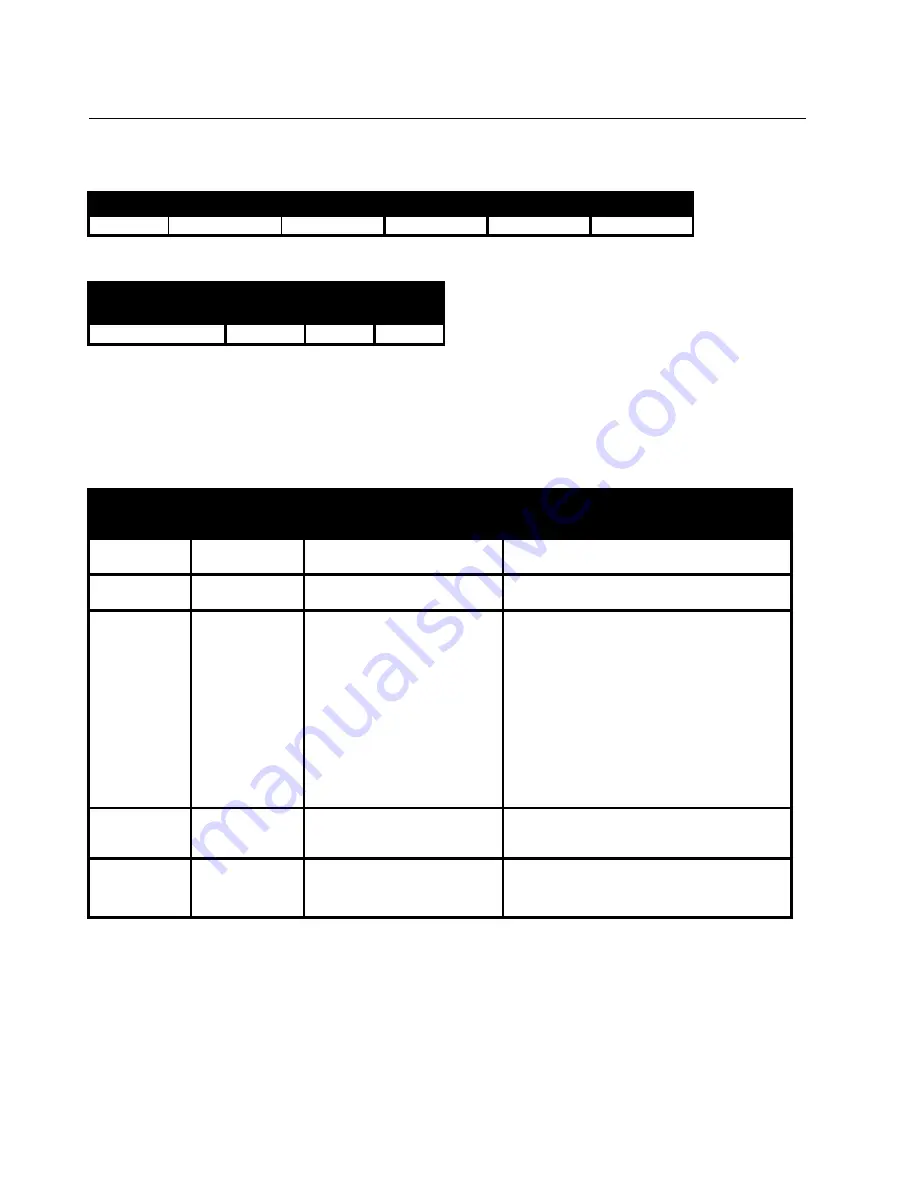

Get System Status (0x2F)

Command Message

Status Response with Position Data

Example of how to get the blink code status of the PXR (assumes product address is 00)

Send command

>06002F93

response =

<805022

This would indicate the unit has a status of 8050 (check digits 22), blinking 5 times and that the unit has not successfully been

through

LEARN

mode.

PXR Blink Codes

Fault Conditions

IMPORTANT ! :

If the PXR control system sees a fault condition it will stop the operation. A green light will flash on the main

control board (visible through the control housing). A red light will flash the same code on top of the unit.

NOTE:

Each time the PXR receives an IR command, the red light will blink on top of the unit.

NOTE:

If there are repeated faults or faults not listed in PXR Blink Codes table, please contact Chief Customer Service.

SOM

Product ID

Address

Command

Check Code

EOM

>

06

XX

2F

XX

<CR>

SOM

System

Status

Check

Code

EOM

<

XXXX

XX

<CR>

Fault Code

(# of blinks)

System Status

(hexadecimal)

Description

Corrective Action

0

0x0000

System is OK and working

normally

None

2

0x0020

Main control board lost

communication to the I/O board

Verify the ribbon cable connecting the I/O board to

the Main control board has not come loose.

4

0x0040

thru

0x0049

System has stalled

Pressing [STOP] for 5 or more seconds will clear

this error. It doesn’t fix the problem, but will make the

PXR operational again.

• Weight of display has changed. Re-run the LEARN

mode sequence.

•Cables are tied too tight. Review cable

management, leaving enough slack so that

cables are never too tight.

•PXR path is obstructed. Remove any obstructions

from path of PXR. Press [STOP] for 5 or more

seconds to clear error code.

5

0x8050

Not programmed (or has lost

programming) to

recognize size of screen

Re-run the LEARN mode sequence.

6 or 10

0x8060

thru

0x0061

Pan limit switches are not

timed correctly

Contact Chief Customer Service

Содержание PXR

Страница 29: ...Installation Instructions PXR 29 ...

Страница 30: ...PXR Installation Instructions 30 ...

Страница 31: ...Installation Instructions PXR 31 ...