WIRING DIAGRAMS 11

WIRING DIAGRAMS 12

With the low current and voltage levels found in some

circuits, it is important that the best possible bond at all

wire splices be made by soldering the splices.

Use care when probing the connections or replacing

terminals in them, it is possible to short between opposite

terminals. If this happens to the wrong terminal part, it is

p o s s i b l e that d a m a g e may be d o n e to c e r t a i n

c o m p o n e n t s . Always use j u m p e r wires between

connectors for circuit checking. Never probe through the

Weather-Pack seals.

When diagnosing for possible open circuits, it is often

difficult to locate them by sight because oxidation or

terminal misalignment are hidden by the connectors.

Merely wiggling a connector on a sensor or in the wiring

harness may correct the open circuit condition. This

should always be considered when an open circuit is

indicated while troubleshooting. Intermittent problems

may also be caused by oxidized or loose connections.

METRl-PACK CONNECTORS

The Metri-Pack connectors use a pull-to-seat type

terminal, as shown in figure 19. The special tool required

to remove the terminal is J-35689-A terminal remover. If

removal is attempted with an ordinary pick, there is a

good chance that the terminal will be bent or deformed.

Refer to figure 19.

[<>] Remove or Disconnect (Figure 19)

Tool Required:

J-28742 Terminal Remover

1. Primary lock (121) by lifting.

2. Connector sections.

3. Secondary lock (125) by spreading the sides of the

hasp, thus clearing the staples and rotating the

hasp (127).

4. Terminal (131) by using J-28742 (128).

* Snip off the old terminal assembly.

5. 5 mm of the wire insulation (130).

[^]

Clean

Terminal barrel (124).

[><] Install or Connect (Figure 19)

1. Terminal insulator (134) on the wire. Slide the

insulator back on the wire about 8 cm (3 inches).

2. Terminal (131) on the wire.

* Roll crimp (132) and solder the terminal

3. Terminal insulator (134) and the roll crimp (133).

4. Terminal into the connector.

5. Secondary lock (125).

6. Connector sections until the primary lock (121)

engages.

METRI-PACK CONNECTOR REPLACEMENT

[<>] R e m o v e or Disconnect (Figure 19)

Tool Required

J-35689-A Terminal Remover

1. Primary lock (121) by lifting.

2. Connector Body (1ST).

3. Connector seat (120) by pulling the seal back onto

the wires away from the connector body (137).

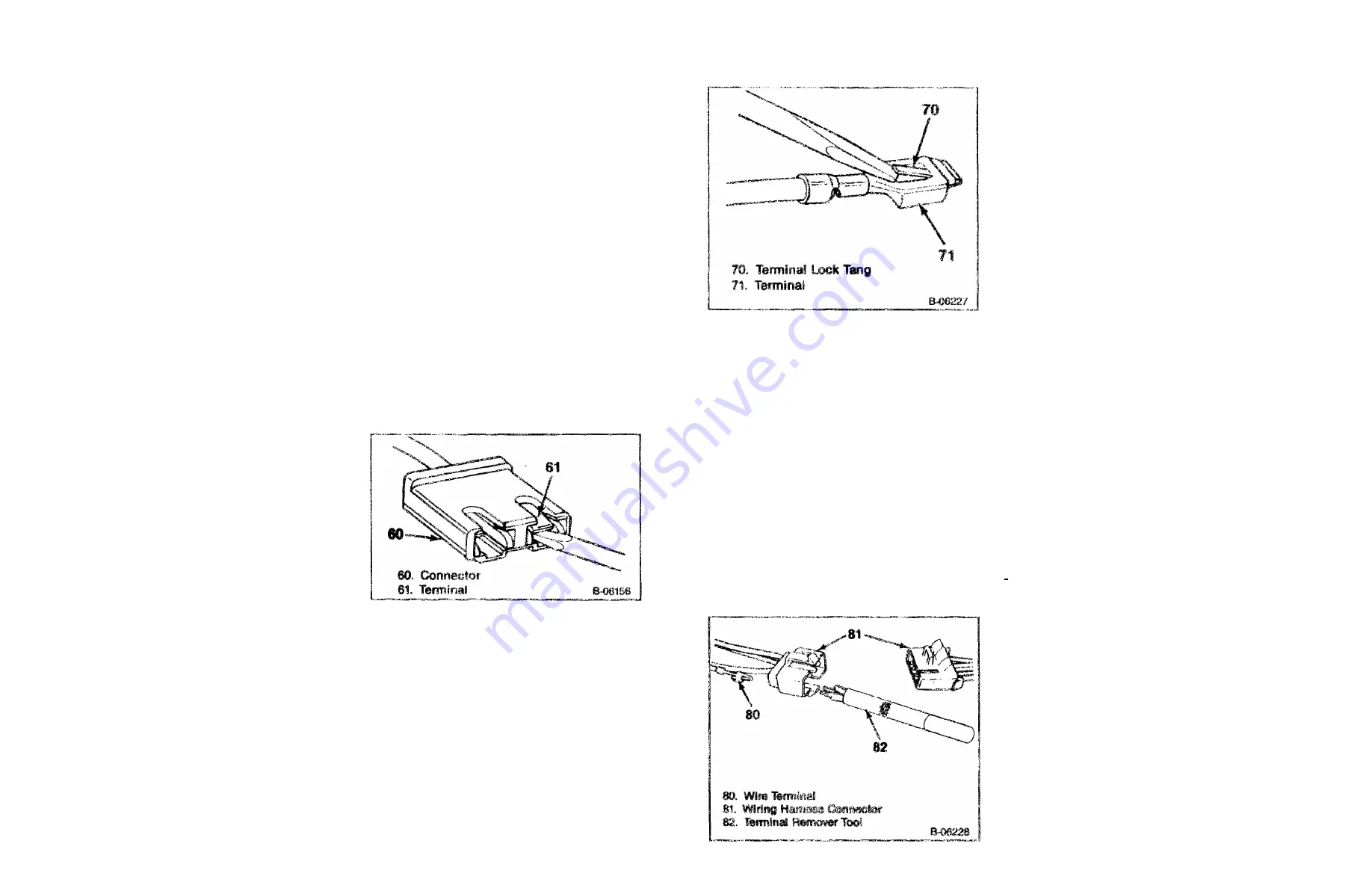

Figure 18—Twin Lock Connector Terminal

Figure 17—Resetting the Lock Tang

WEATHER-PACK CONNECTORS

Special connectors known as Weather-Pack connectors

(figure 19) require a special tool J-28742 for servicing.

This special tool is required to remove the pin and sleeve

terminals. If removal is attempted with an ordinary pick,

there is a good chance that the terminal will be bent or

deformed. Unlike standard blade-type terminals, these

terminals cannot be straightened once they are bent.

Mate sure that the connectors are property seated and

all of the sealing rings in place when connecting the

leads. The hinge-type flap provides a back-up, or

secondary locking feature for terminals. They are used to

improve the connector reliability by retaining the terminals

if the small terminal lock tangs are not positioned

properly.

Molded-on-connectors require complete replacement of

the connection. This means splicing a new connector

assembly into the harness. Environmental connections

c a n n o t b e r e p l a c e d with s t a n d a r d c o n n e c t i o n s .

Instructions are provided with the Weather-Pack

connector and terminal packages.

Figure 16—Removing the Terminals from

the Connector

WIRING CONNECTOR TERMINAL

REPLACEMENT (TWIN LOCK TYPE)

[<>] Remove or Disconnect (Figure 18)

Tool Required:

J-22727 Terminal Remover

1. Connector lock tangs.

2. Terminal lock tangs.

3. Terminal

[><] Install or Connect

1. Pry out the tangs

2. Terminal into the connector.

.

CIRCUIT MAINTENANCE

AND REPAIR

MAINTENANCE AND REPAIR

All electrical connections must be kept clean and tight.

Loose or corroded connections may cause a discharged

battery, difficult starting, dim lights, and possible damage

to the generator and regulator. Wires must bo replaced if

insulation becomes burned, cracked, or deteriorated.

To splice a wire or repair one that is frayed or broken

always use rosin flux solder to bond the splice and

insulating tape to cover all splices or bare wires.

When replacing wire, it is important that the correct size

wire be used as shown on applicable wiring diagrams or

parts book. Each harness or wire must be held securely in

place to prevent chafing or damage to the insulation due

to vibration.

Never replace a wire with one of a. smaller size or

replace a fusible link with a were of a larger size.

WRING CONNECTOR TERMINAL

REPLACEMENT (BLADE TYPE)

[<>] Remove or Disconnect (Figure 10)

1. Terminal lock tang.

2. Terminal (61).

[><] Install or Connect (Figure 17)

I. Pry up on the tang (70).

2. Terminal into the connector.

ON-VEHICLE SERVICE

Wiring harnesses are joined by using a multiple plug

and receptacle connector block, or a terminal post

chassis junction block. In the instrument panel area

plastic insulated blade-type connectors and screw-type

terminals are used.

Each harness or wire must be held securely in place by

clips or other holding devices to prevent chafing of the

insulation.

WIRE SIZE

Wire size in a circuit is determined by the amount of

current, the length of the circuit and the voltage drop

allowed. Wire size is specified using the metric gage. The

metric gage describes the wire size directly in cross

section area measured in square millimeters.

WIRE SIZE

CONVERSION TABLE

METRIC AWG

SIZE SIZE

(mm)

2

0.22 24

0.35 22

0.5 20

0.8 18

1.0 16

2.0 14

3.0 12

5.0 10

8.0 8

13.0 6

19.0 4

32.0 2

40.0

1

50.0

0

62.0

00

Содержание P 1989

Страница 10: ......

Страница 11: ......

Страница 12: ......

Страница 13: ......

Страница 14: ......

Страница 15: ......

Страница 16: ......

Страница 19: ......

Страница 20: ......

Страница 21: ......

Страница 23: ......

Страница 26: ...2 2 0 RED THERMO HW FUSIBLE LINK 2 8 BLK RED 30 2 O m I C H m 3 2 m 3 0 z 1...

Страница 28: ......

Страница 29: ...15 8 BLK TO A C COMP l P CLUSTER CONN FUSE BLOCK IGNITION L 2 5 V 6 SECTION A PAGE 21...

Страница 32: ...l P CLUSTER CONN TO GENERATOR IGNITION L05 L19 V 8 SECTION A PAGE 24 FUSE BLOCK REAR...

Страница 34: ...HOT FUEL HANDLING HOT FUEL HANDLING L05 L1 9 V8 SECTION A PAGE 26...

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 41: ......

Страница 42: ......

Страница 47: ...439 8 PNK BLK 439 8 PNK BLK 439 8 PNK BLK ELECTRONIC CONTROL MODULE INPUTS L05 L 1 9 V 8 SECTION A PAGE 39...

Страница 49: ...TO ECM ELECTRONIC CONTROL MODULE OUTPUTS L05 L19 V8 SECTION A PAGE 41...

Страница 52: ......

Страница 53: ......

Страница 54: ......

Страница 64: ...TO GLOW PLUG RELAY CONTROLLER INDICATOR LAMPS SECTION A PAGE 56 TO AUTO TRANS KICKDOWN SOLENOID M40...

Страница 71: ......

Страница 72: ...TO ROOF MARKER LPS RPO 401 9 8 BRN 9 8 BRN RADIO EQUIPMENT RPO UM6 UP8 SECTION A PAGE 64...

Страница 74: ......

Страница 77: ...150 1 0 BLK C0 m g o z im o o 30 m 3D O m n O G C D m 30 30 O o o C O...

Страница 86: ......

Страница 93: ......

Страница 97: ...START IGNITION LT9 V8 BODY S TY LE 42 SECTION B PAGE 4 FRONT REAR...

Страница 99: ...POWER DISTRIBUTION L25 BODY STYLE 4 2 SECTION B PAGE 6 FRONT FUSE BLOCK REAR...

Страница 100: ...FUSE BLOCK REAR POWER DISTRIBUTION LE8 V 8 BODY S TY LE 32 SECTION B PAGE 7...

Страница 101: ...POWER DISTRIBUTION LT9 V 8 BODY STYLE 4 2 SECTION B PAGE 8 FUSE BLOCK REAR...

Страница 102: ...32 BLK BATT CABLE FRONT FUSE BLOCK REAR POWER DISTRIBUTION L 0 5 V 8 SECTION B PAGE 9...

Страница 110: ...r ru___n f i r BATTERY 2 FRONT REAR START IGNITION L 2 5 6 CYL BODY STYLE 4 2 SECTION B PAGE 17...

Страница 113: ...START IGNITION L05 V8 SECTION B PAGE 20...

Страница 117: ...AIR DIVERT SOLENOID NA5 AIR CONTROLLER NA5 IDLE STOP SOLENOID EMISSION CONTROLS L25 SECTION B PAGE 24...

Страница 121: ...CD FUEL SHUT OFF VALVE 12020274 GLOW PLUGS LL4 DIESEL SECTION B PAGE 28...

Страница 126: ...TO ECM 439 8 PNK BLK ELECTRONIC CONTROL MODULE L05 V8 SECTION B PAGE 33...

Страница 137: ...X...

Страница 138: ...r...

Страница 139: ...s...

Страница 140: ...s...

Страница 141: ......

Страница 142: ...i a...

Страница 143: ......