2

Included Accessories:

USB cable, charger adapter, cal. cert. printer

cable, square driver adapter connector

Optional Accessories:

RS-232 cable, Rundown adapters,

Printer. Note: Software available for free at www.shimpoinst.com

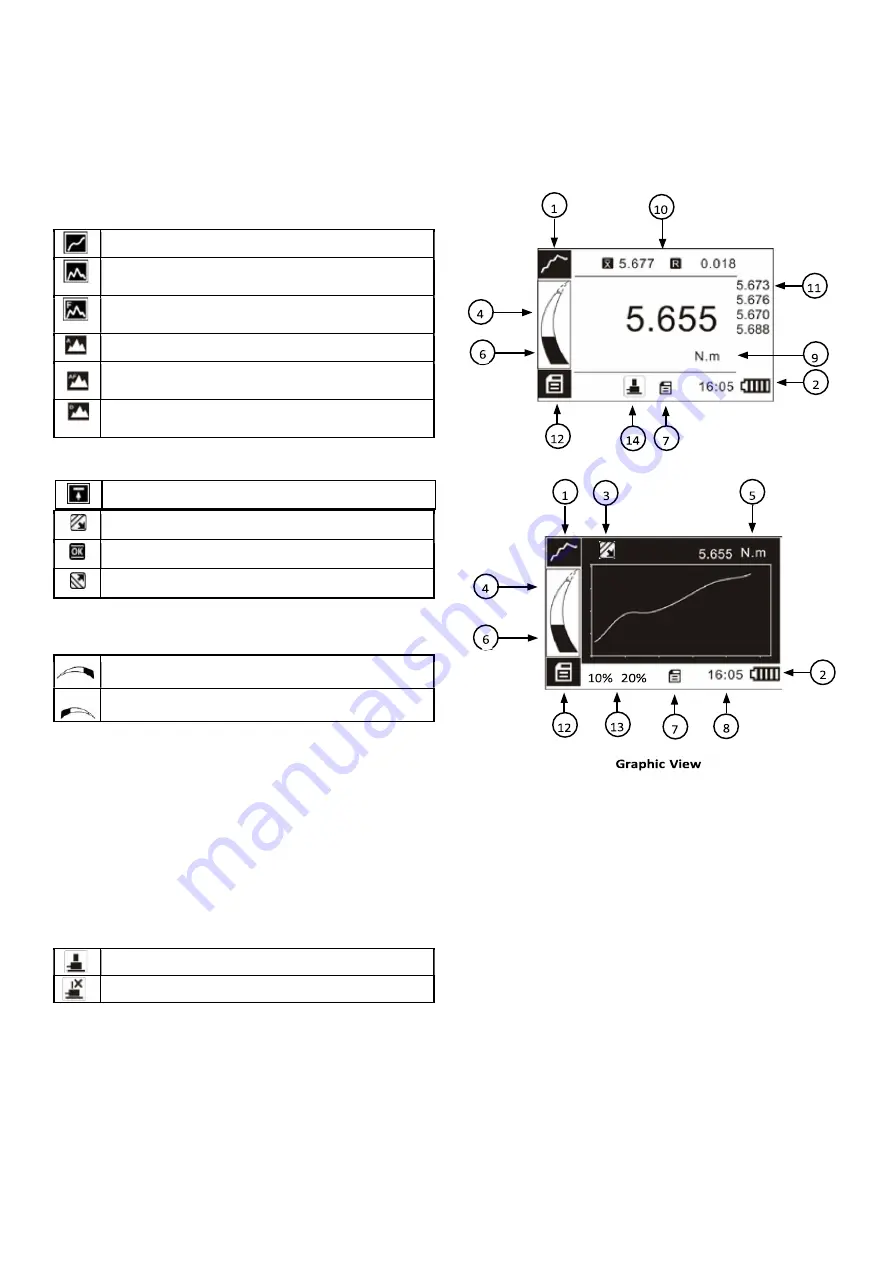

1. LCD SCREEN STANDARD VIEW

Test Mode Icons:

2.

Battery Icon: Battery level or charging status. Flashes when gauge

needs to be recharged.

Digital View

3.

OK/OV Preset Indicator:

4.

Torque Icons: Indicates force direction.

5.

Current measured value

6.

Analog Bar: Indicates current position within full scale. When the bar enters the area enclosed by the dotted line,

this signifies the full scale capacity is exceeded by an overload condition.

7.

Storage Icon: Indicates data is being saved.

8.

System time

9.

Units Indicator: Selected engineering unit.

10.

Statistics X: Average; R: Variance

11.

Data list: Five Point Measurement in Peak & First Peak Modes12. Key Setting Mode: Printer Icon Key press will print.

Disc icon key will store reading.

13.

Double Peak Mode Percentages

14.

Sensor Icons: TTC-E Only

Sensor is Connected

Sensor not Connected

Track: Real Time, live measuring mode

Peak: Reading will not change until a higher value is measured

First Peak: Captures First Peak after a decrease has been detected.

Drop Ratio set in menus.

Auto Peak: Resets Peak after a programmed time period

Auto First Peak: Resets the First Peak after a programmed time

period. First Peak drop Ratio set in menus

Double Peak: Captures two First Peak values. Both drop ratios set

in drop ratio menu

Preset: Set the upper & lower limit for GO/NG testing

Under Lower Limit

Between Low Limit & Upper Limit

Over Upper Limit

Clockwise (CW)

Counterclockwise (CCW)