5

Product Manual - VaporMan 125

®

Manifold Vaporizer System

General

The VaporMan125 Manifold Vaporizer System is designed

to combine two bulk carbon dioxide tanks or one carbon

dioxide Perma-Cyl

®

MicroBulk Storage System tank on a

reliable, economical basis. The unit is intended to fulfill the

high flow requirements of distributors for micro-breweries,

stadium applications, industrial applications, and various

other high-flow applications.

The VaporMan 125 system comes with all the necessary

fittings to connect two Carbo-Max

®

750 Bulk CO

2

System

tanks to the unit A separate kit can be bought along with the

VaporMan 125 system for two Carbo-Max 1000 tanks There

is also a specific part number for a VaporMan 125 system

Perma-Cyl tank

System Overview

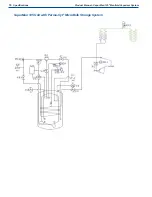

The VaporMan 125 system consists of two vaporizers, one

parallel and one series, and a manifolding sub-assembly The

CO

2

enters the manifolding section and is combined before

being routed to the parallel vaporizer The parallel vaporizer

vaporizes the CO

2

into cold gas The cold gas then enters the

series vaporizer, which warms the cold gas to an adequate

temperature before being sent downstream to equipment

The design and construction of the VaporMan 125 system

is aimed at building the most efficient and affordable

vaporizing unit available Engineered as a complete high

flow vaporizing system, the VaporMan 125 system can be

coupled with a high flow regulator to achieve flow rates

of 125 lbs/hour (56 kg/hr) The manifolding section of the

VaporMan 125 system makes installation simple and straight

forward The unit is essentially a plug and play assembly

The vaporizers are connected in a specific order and the

vaporizer selection was intentional The parallel vaporizer is

used to vaporize the liquid into cold gas The gas is then sent

through the series vaporizer in order to warm the gas and

prepare it to be used downstream

The VaporMan 125 system is protected from over-

pressurization by a primary safety relief valve set at 350

psig This has been included for the time when the system

may be mistakenly isolated or if a blockage occurs

Physical Description

VaporMan 125 Components

The components on the manifold section can be used in three

ways:

• Two Carbo-Max 750 or 1000 tanks

• One Carbo-Max 750 or 1000 tank

• One Perma-Cyl tank

The manifold section provides four connections, a pressure

gauge and an economizer regulator The manifold section is

mounted to a panel that is conveniently located for ease of

hook up. The connections are standard 5/8" ODT 45° flare.

This is the fitting needed for the standard fill hoses that are

used on all beverage tank installations

Vaporizing Circuit

The vaporizing circuit includes two vaporizers One

vaporizer is a parallel ambient vaporizer and the other is

a series ambient vaporizer The vaporizers are connected

in order to maximize the vaporization of the product The

parallel vaporizer is used to quickly vaporize liquid into gas

The series vaporizer is used to warm the gas, not vaporize

liquid Each of the vaporizers has a 600 psi maximum

allowable working pressure

Safety Pressure Relief Section

The safety relief is a 350 psi pressure relief device This is to

relieve pressure in the event liquid were to be trapped in the

vaporizers or in case of fire.

*Each VaporMan 125 PED model is equipped with relief

devices with set pressures of 20 68 Bar

Introduction

Содержание VaporMan 125

Страница 2: ......

Страница 16: ......

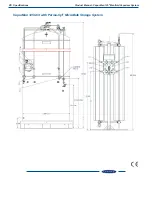

Страница 22: ...18 Specifications Product Manual VaporMan 125 Manifold Vaporizer System Set up and Dimensions VaporMan 125 Unit...