7

Product Manual - VaporMan 125

®

Manifold Vaporizer System

Initial Inspections

When the tanks and/or VaporMan 125 system are first

received they should be inspected for shipping damage

Never fill a damaged tank or use a damaged VaporMan 125

system

If the tanks arrive with zero pressure, they should be

pressurized and checked for leaks

Filling Procedures

Before filling the tank it should be visually inspected for

possible damage or unsuitability for intended use If damage

is detected (i.e. serious dents, loose fittings, etc.) remove the

unit from service and conduct the necessary repairs as soon

as possible

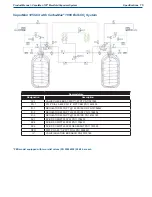

It is recommended that when using two Carbo-Max

®

750 or

1000 Bulk CO

2

System tanks that you install two fill boxes.

This will help in confirming that both tanks are completely

full. If there are no fill boxes, then you can fill the tanks

individually. When there are no fill boxes, please make sure

you have an adequate way to pipe the vent circuits outdoors

in a safe manner

Installing the VaporMan 125 Unit

The VaporMan 125 unit is assembled with a stand and base

The base has a hole in each corner This will serve as the

location for the bolts that will be used to anchor the unit

to the floor. The VaporMan 125 unit should be anchored

to the floor in an accessible location and conveniently

located for easy connections A place that has circulation is

recommended to aid in melting the ice that might build up on

the vaporizers during operation The VaporMan 125 unit will

then need to be connected to the tank or tanks in order to be

used

Note:

A video presentation of the installation

and instructions for the VaporMan 125

system can be found online at

youtube com/user/chartindustries

Operations

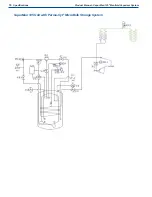

First, there are some parts that must be removed from the

two tanks that will be used Detail drawings of the parts that

are to be removed and the parts to be added are included on

the next pages of this manual The Gas Use and Economizer

sections will change on the Carbo-Max 750 Bulk CO

2

System, and the Gas Use, Economizer, and Pressure Building

sections will change on the Carbo-Max 1000 Bulk CO

2

System The parts that are removed may be kept and used

in other locations if they are in good condition Some of the

parts to be removed will actually be reused when adding the

necessary fittings to connect to the VaporMan 125 unit.

Caution! Make sure to plumb the tanks as

we recommend in the following

Plumbing Procedures section.

Do not use any other methods.

The plumbing configuration and

specific fittings have been tested

and proven to work properly.

Other methods of plumbing or

connecting to the VaporMan 125

system must be cleared through

Chart before continuing. Chart is

not responsible for improperly

plumbed tanks or improperly

connected VaporMan 125 units.

This could lead to issues with

the system, damage or poor

performance.

Содержание VaporMan 125

Страница 2: ......

Страница 16: ......

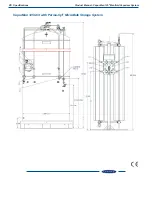

Страница 22: ...18 Specifications Product Manual VaporMan 125 Manifold Vaporizer System Set up and Dimensions VaporMan 125 Unit...