GB-1

Contents: General Information on

Installation and Use:

Details of Contents:

Page 1

Before You Begin:

Page 2

Check List:

Page 2, figs. -

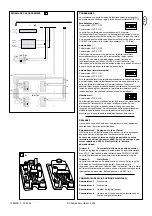

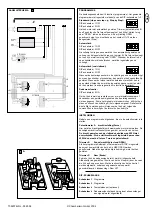

Overview of Installation:

Page 2

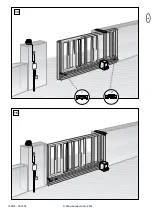

Installation of Rack Bar:

Page 2, fig.

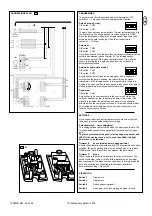

Electrical Installation:

figs. -

Installation of Base Plate:

Page 2

Mounting Drive on Base Plate:

Page 2, figs.

+

-

A

Drive Release Mechanism:

Page 2, fig.

Limit Switches:

Page 2, fig.

Light Barrier:

Page 3, figs.

A

Flashing Lamp:

Page 3, figs. -

External Antenna:

Page 3

Initial Operation:

Page 3

Maintenance Work:

Page 3, figs.

Typical System Set-up:

Page 4, fig.

Teaching in Remote Control:

Page 5, fig.

Technical Data:

Page 3

CE Conformity Certificate:

Page 4

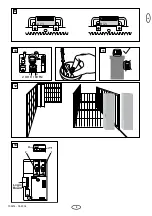

Contents in HC100/HC500 packs

(1)

Drive motor (1x)

(2)

Capacitor (pre-installed) (1x)

(3)

Limit switch A or (1) (1x)

(4)

Limit switch B or (2) (1x)

(5)

Base plate for drive motor (1x)

(6)

Accessories bag

(7)

Control unit with pre-installed radio receiver(1x)

(8)

Flashing lamp 100287

(9)

Light barrier (pair) 263EML

(10)

Remote control 84333EML

Optional Accessories

(11)

Remote control 84335EML

(12)

Remote control 84330EML

(13)

External Antenna ANT4X-EML

(14)

Key switch 41EML

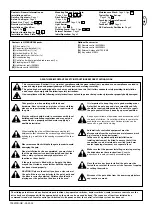

READ THESE IMPORTANT SAFETY INSTRUCTIONS BEFORE STARTING WORK

CAUTION! Only use the drive if you have a clear view of

the gate, if there are no obstacles in the gate's path and

the drive is correctly adjusted. Children should not be

playing near the gate when the drive is to be used.

Disconnect the gate drive from the power supply before

any repairs are made.

This symbol means 'Caution!'; it is a sign that compliance with the given instruction is required as non-compliance can lead to

persons being injured and property damaged. Please read such warnings carefully.

This gate drive has been designed in such a way and tested to ensure that it offers adequate safety providing its installation

and use exactly comply with the following safety instructions.

Non-compliance with the following safety instructions can lead to persons being seriously injured or property badly damaged.

The sliding gate drive can be activated via push-buttons, key-operated switches, keyless switches (radio) or remote control; once the

drive has been disengaged with the appropriate key, the gate can be opened by hand. The sequence of functions initiated by a

command issued via a remote control, push-button, etc. depends on how the control's electronic system has been set.

Electric cables should be laid in accordance with local

building and installation regulations and may only be

connected to a properly earthed mains supply by a

qualified electrician.

When installing the drive, sufficient clearance must be left

between the item driven and the surrounding parts of the given

building (e.g. a wall) due to the opening movement of the item

driven.

Automatically controlled equipment must be

disconnected from the mains when maintenance work

e.g. cleaning is being performed.

In the case of a permanently laid installation, an

isolating device must be fitted to ensure that all the

connections can be isolated via a switch (min. 3mm

contact opening clearance) or a separate fuse.

Take great care when working with tools and

hardware. Never wear rings, watches or loose clothing

when you are performing installation or repair work on

the gate.

Make sure that the persons installing, servicing or using

the drive observe these instructions.

Keep the

instructions in a safe yet readily accessible place.

Please remove all locks fitted to the gate in order to avoid

damaging the gate.

It is important to keep the gate in good working order.

Gates that do not open and close smoothly and fully

should be repaired without delay. Do not try to repair

the gate yourself. Have it done by a person qualified.

Keep any extra items of equipment and accessories out of

the reach of children. Do not allow children to operate the

push-buttons or remote control. Serious injuries can be

caused by a gate that is closing.

Once installation has been completed, you must check

that the mechanism is correctly adjusted and that the

drive, safety system and emergency release all

function as they should.

Once the drive has been installed, the gate must be

tested to ensure that there is no risk of persons trapping

or cutting themselves.

If the gate system is fitted with a slip-gate, the drive

may not be started or move further until the slip-gate

has been closed properly.

1

4

5

7

8

9

10

11

12

2

3

6

6

13

A

C

709207B-GB - 05.2004

Содержание MotorLift HC100

Страница 27: ...1 200 215 12 40 60 28 30 1 2 160 mm 100 m m 180 mm M10x50 270 mm 75 mm 4 5 6 6 A 7 709276 05 2004 1...

Страница 28: ...2 A 1 B 2 2 3 0 V 50 Hz 9 7 6 5 8 2 1 3 4 0 8 10 11 12 13 N L 2 1 Logic Board 2 1 709276 05 2004 2...

Страница 29: ...3 709276 05 2004 Chamberlain GmbH 2004 1 2 14 15...