Page 10

SKU 97080

For technical questions, please call 1-800-444-3353.

Connect a high pressure air hose (not included) to the Pressure Regulator (24).

1.

Connect an air blow gun (not included) to the other end of the air hose. Turn the

compressor on. Refer to Hose Connection Instructions on page 8.

When the maximum air pressure, 100 PSI, is reached as indicated by the Tank

2.

Pressure Gauge (26), the motor will stop.

Blow air out of the blow gun while you turn the Pressure Regulator (24) knob

3.

to adjust Pressure Regulator (24). Turn the Pressure Regulator (24) knob

counterclockwise to decrease the PSI, turn it clockwise to increase the PSI.

When the Regulated Pressure Gauge (70) shows the pressure that you want to

limit the compressor to, the Pressure Regulator (24) is set.

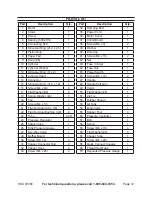

(See Figure C.)

Between the Pressure Regulator knob and valve body, a narrow ring acts as a

4.

lock-ring for the knob. Rotate the ring in a counterclockwise direction and tighten

it against the knob to secure the setting.

(See Figure C.)

NOtE

: When the maximum air pressure, 100 PSI, is reached as indicated by the

Tank Pressure Gauge (26), the motor will stop. The Compressor will automatically

restart when the air pressure drops below 85 PSI.

(See Figure C.)

to Stop the Compressor:

Push the ON/OFF Power Switch (45) to its “OFF” position.

1.

Unplug the Air Compressor from its electrical outlet. Place a collector can (not

2.

included) under the Air Tank (53) and turn the Drain Valve (54) counterclockwise.

Pull out on the Safety Valve (25) to release all remaining air pressure from the

3.

Air Tank (53).

(See Figure C.)

This will not only drain the air, but will also drain

any accumulated moisture. After all air is drained, turn the Safety Valve (25)

clockwise.

Squeeze the trigger on the pneumatic tool to release any remaining air pressure

4.

from the tool. Then disconnect the air hose from the tool, and store the tool in a

clean, dry, safe location out of reach of children.

Remove any moisture in the Air Tank (53) by opening the Tank Drain Valve (54).

5.

Then, retighten the Drain Valve (54).

(See Figure b.)

Allow the Air Compressor to completely cool. Then store the unit in a clean, dry,

6.

safe location out of reach of children.

REV 07k

to Adjust the Air Regulator: