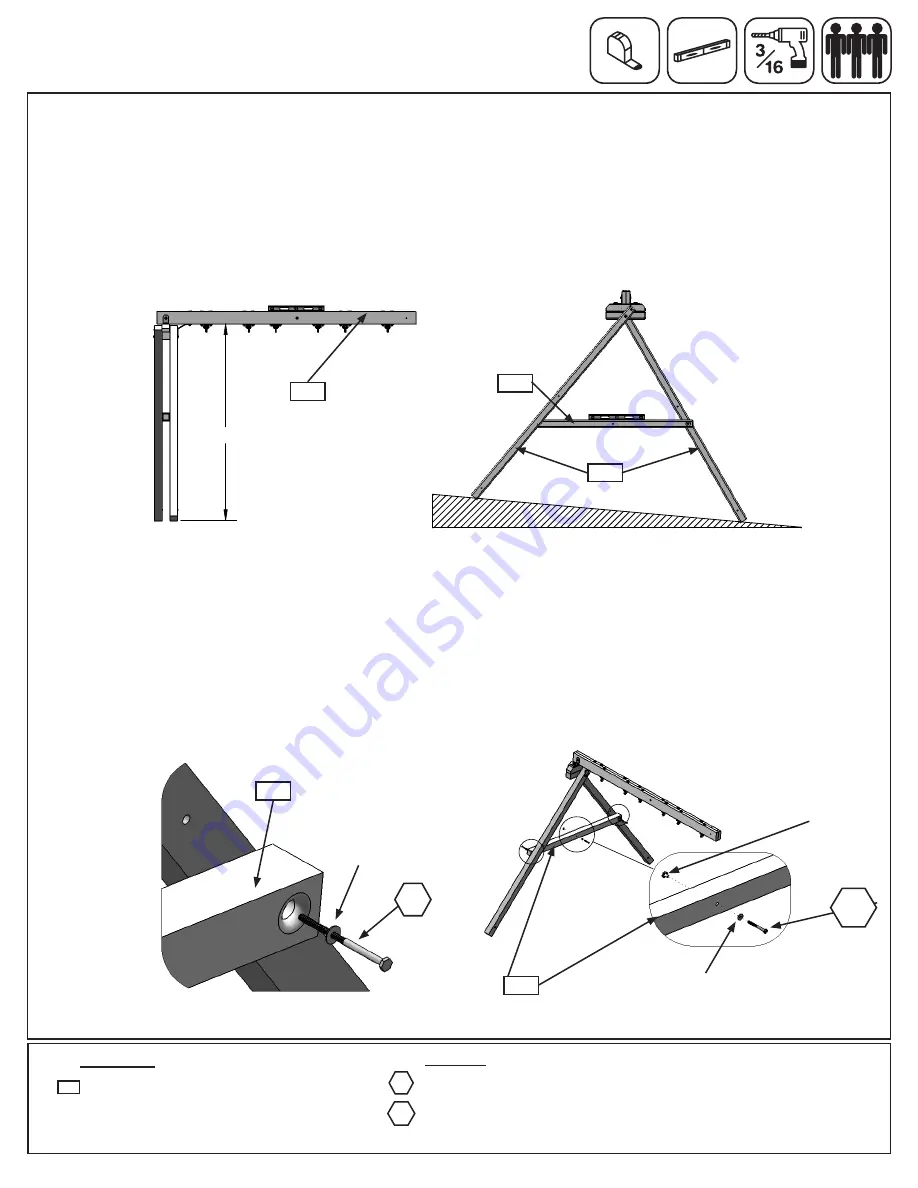

Fig. 38.1

360

85"

85"

5/16” T-Nut

290

5/16” Flat

Washer

5/16” Flat

Washer

LS9

270

290

282

WB8

Step 25: Attach Cross Support

Hardware

Wood Parts

Pre-drill all holes using a 3/16” drill bit before installing the lag screws.

A:

Check to make sure the (270) Engineered SW Beam is level and the bottom of the beam to the ground

measures 85”. (fig. 25.1)

B:

To adjust for uneven ground, raise or lower the (290) Support Cross on the (282) SW Post. Make sure the

Support Cross is level prior to attaching with the lag screws. (fig. 25.2)

2 x

5/16 x 4-3/4” Lag Screw

(5/16” flat washer)

1 x

5/16 x 2-3/8” Wafer Bolt

(5/16” flat washer, 5/16” t-nut)

WB8

LS9

1 x

Support Cross FSC 2-1/2 x 3 x 64”

290

C:

Place (290) Support Cross between (282) SW Post at the previously determined spot and fasten with 1

(LS9) 5/16 x 4-3/4” Lag Screw (with flat washer) per side. (fig. 25.3 and 25.4)

Notice one side is fastened on

the outside and one on the inside. It is important that each side is positioned exactly the same as the

diagram. (fig. 25.3 and 25.4) Tighten the lag screw when you are sure (290) Support Cross is level.

D:

Attach 1 (WB8) 5/16 x 2-3/8” Wafer Bolt (with flat washer and t-nut) to (290) Support Cross through the

middle hole. (fig. 25.3)

IMPORTANT! MAKE SURE THE BOLT IS ATTACHED TO MINIMIZE CHECKING OF

WOOD.

Fig. 25.1

Fig. 25.4

Fig. 25.2

Fig. 25.3

290

90

Содержание WESTON LODGE DELUXE - F25529

Страница 129: ...NOTES 129 support cedarsummitplay com ...